A raw material tape coiler for road construction water pipe threaded mouth

A technology for road construction and raw material tape, which is applied in thin material handling, transportation of filamentous materials, transportation and packaging, etc. problem, to achieve the effect of convenient connection and tight winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

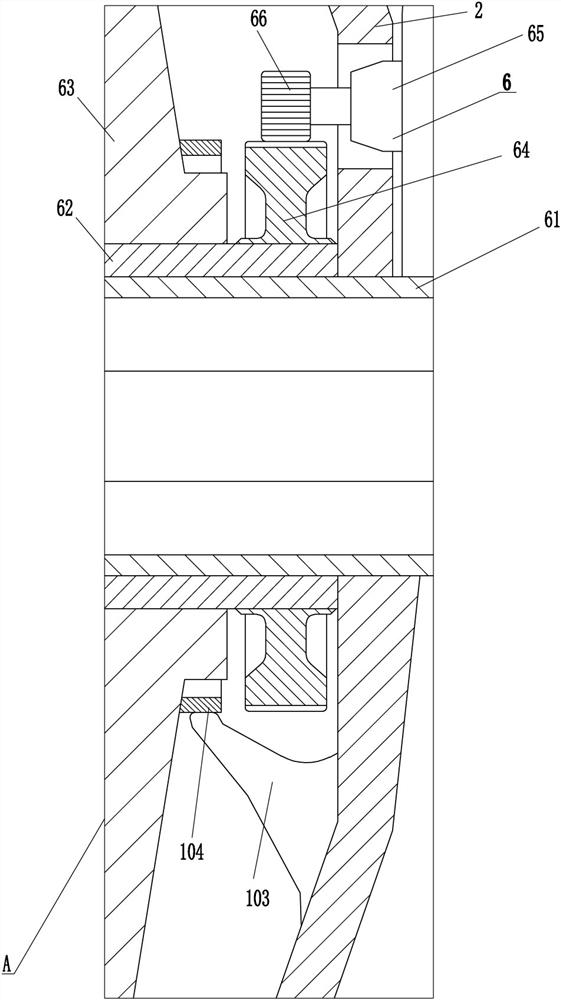

[0028] A raw material tape coiler at the threaded mouth of a water pipe for road construction, such as Figure 1-3 As shown, it includes a handle 1, a protective cover 2, a rotating mechanism 6 and a fixed assembly 8, the left side of the handle 1 is connected with a protective cover 2, the protective cover 2 is provided with a rotating mechanism 6, and the rotating mechanism 6 is provided with a fixed assembly 8, The rotating mechanism 6 is used to drive the fixed assembly 8 to rotate, and the fixed assembly 8 is used to fix the raw material belt.

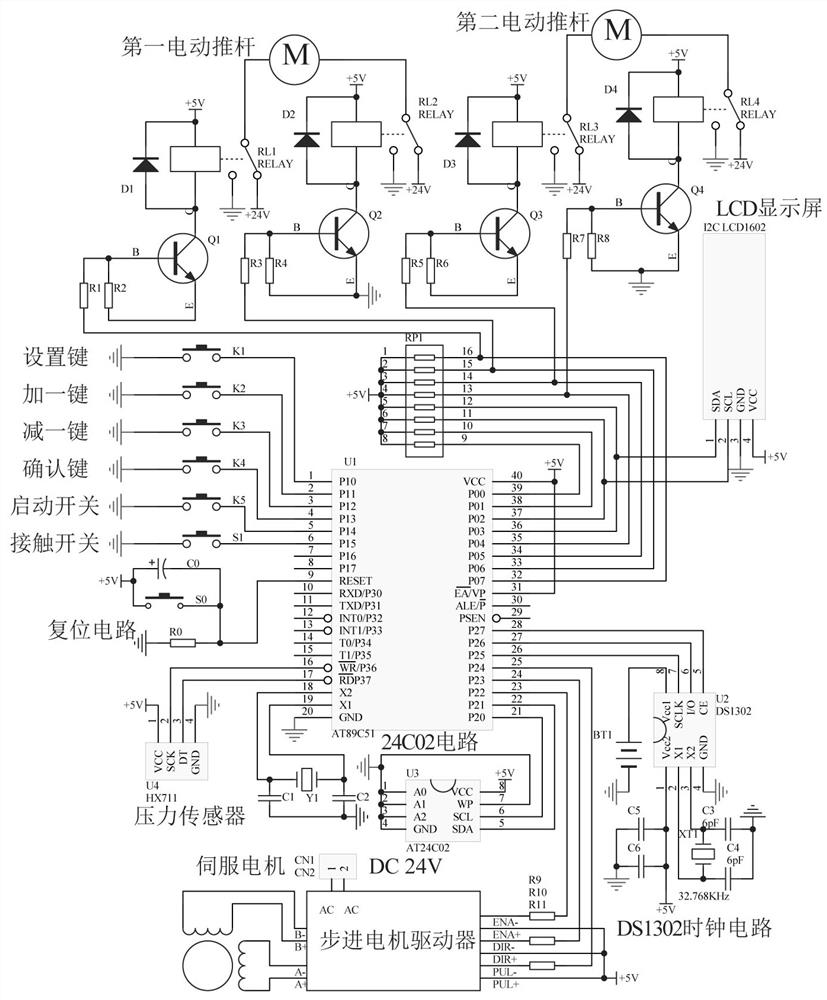

[0029] It also includes a control module, an LCD display 5 and a start switch 7. The left side of the handle 1 is provided with a start switch 7, and both the LCD display 5 and the start switch 7 are electrically connected to the control module.

[0030] The rotating mechanism 6 includes a fixed tube 61, a shaft sleeve 62, a mounting plate 63, a ring gear 64, a servo motor 65 and a gear 66. The middle part of the protective cover ...

Embodiment 2

[0036] This example is on the basis of embodiment 1, as Figure 1-6As shown, a centering assembly 9 is also included, and the centering assembly 9 includes a first electric push rod 91, a contact switch 92, a guide sleeve 93, a pressure sensor 94, a hollow cone 95, a mounting rod 96, a slider 97, an arc Block 98 and spring 910, the first electric push rod 91 is installed on the right part in the fixed pipe 61, the push rod of the first electric push rod 91 is provided with a contact switch 92, and the push rod of the first electric push rod 91 is covered with a guide The sleeve 93 is connected with the hollow cone 95, the guide sleeve 93 is in contact with the contact switch 92, the guide sleeve 93 is connected with the inner wall of the fixed pipe 61, the left end of the first electric push rod 91 is equipped with a pressure sensor 94, the hollow cone 95 is in contact with the pressure sensor 94, and the fixed pipe Both sides up and down in 61 are all connected with mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com