Method for preparing high-purity quartz sand iron ore concentrate from magnetite associated granular quartz

A high-purity quartz sand and magnetite technology, applied in the direction of solid separation, etc., can solve the problems of waste of by-products and tailings, waste of resources, and increase of production costs of enterprises, so as to avoid secondary pollution, ensure quality requirements, and be economical. and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

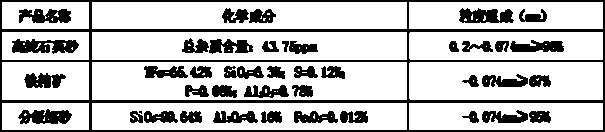

Embodiment 1

[0033] Granular quartz is selected from a foreign country. The quartz particles are cemented. The average size of the quartz particles is about 1-2mm. The appearance is dark brown. The main minerals are quartz, magnetite, ilmenite, and a small amount of feldspar, mica, etc. .

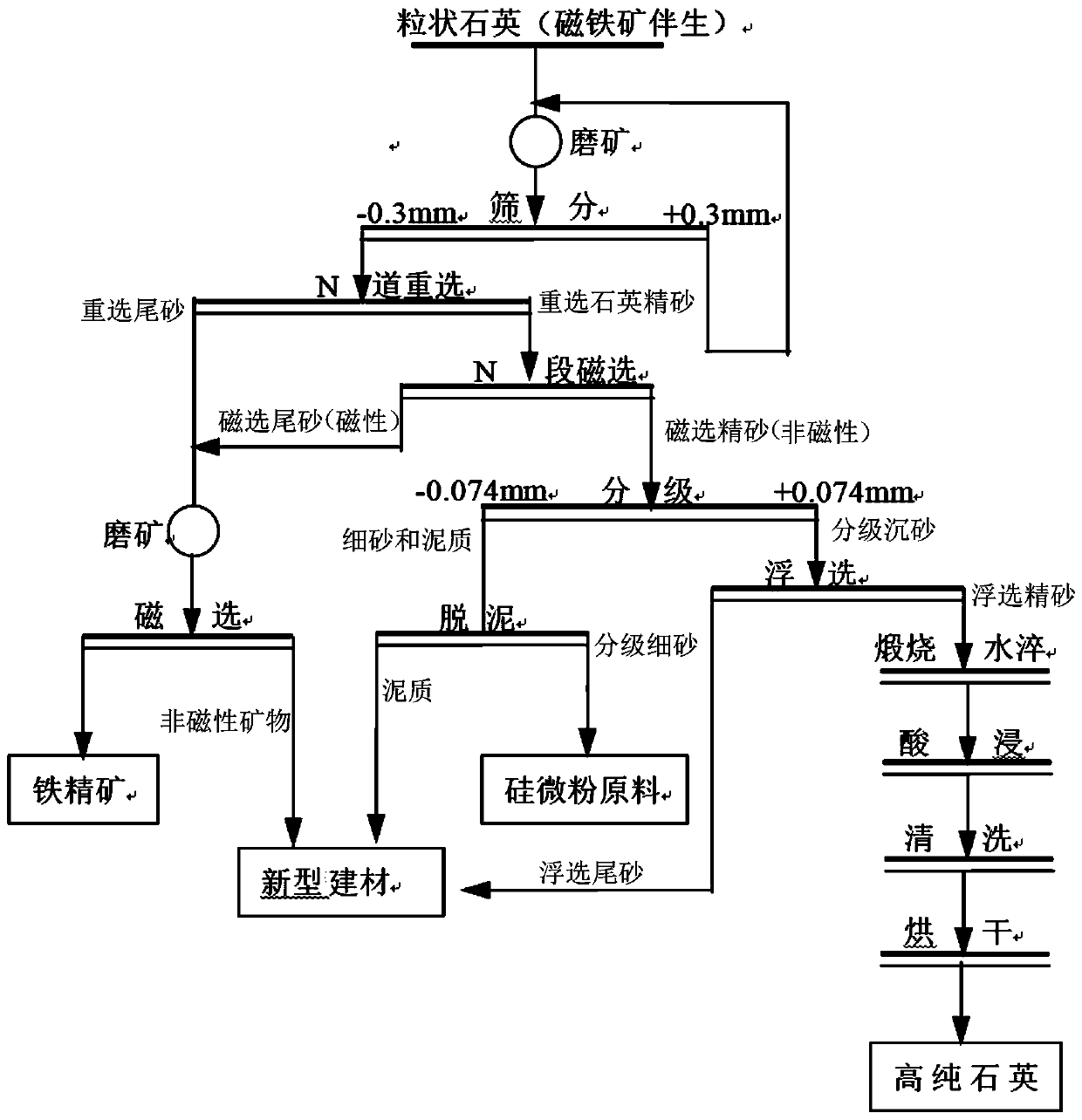

[0034] A method for preparing high-purity quartz sand iron concentrate with magnetite associated granular quartz provided by the invention, see figure 1 , take the following steps:

[0035] (1) Add water to the granular quartz and enter the ball mill for grinding, the pulp concentration is 60%, and the hourly processing capacity is 30t / h;

[0036] (2) The grinding product passes through a 0.2mm high-frequency vibrating screen, and the screened material is returned for regrinding;

[0037] (3) The 0.2mm minerals under the sieve pass through two spiral chutes to obtain the gravity-selected concentrate; the gravity-selected tailings are quartz particles containing ilmenite, magnetite and iron-coated, and...

Embodiment 2

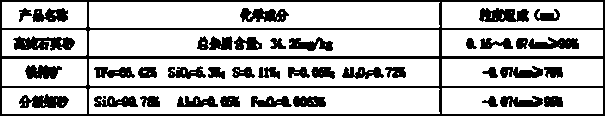

[0047] Granular quartz is selected from pegmatite veins in a certain place in China. Granular quartz particles are cemented and gray in appearance. The main minerals are quartz, magnetite, garnet, biotite, ilmenite, rutile, zircon, etc.

[0048] see figure 1 , using the following beneficiation steps:

[0049] (1) Add water to the granular quartz and enter the ball mill for grinding, the pulp concentration is 50%, and the processing capacity is 20t / h;

[0050] (2) The grinding product passes through a 0.15mm high-frequency vibrating screen, and the on-screen material is returned for regrinding;

[0051] (3) The underscreen is passed through three spiral chutes to obtain gravity-selected fine sand, and the gravity-selected tailings are rutile, zircon, ilmenite, garnet, magnetite and iron-coated quartz particles, and enter the step ( 8);

[0052] (4) Gravity-selected concentrated sand (quartz) undergoes a medium magnetic induction intensity of 0.5T and a strong magnetic induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com