Novel flue gas purification tower

A flue gas purification tower, a new type of technology, is applied in the direction of gas treatment, chemical instruments and methods, and the use of liquid separation agents. It can solve the problems of high investment and operation costs, complex systems, and high power consumption, and achieve strong flue gas purification capabilities. The effect of increasing the number and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] see Figure 4 , and the difference from Example 1 is that the desulfurization efficiency required by this implementation is low, and the amount of absorption required to be sprayed is small. The water washing spray device and demister inside are changed to the flue gas outlet, and the fresh slurry of the absorbent is sprayed into the diffusion pipe at the lower end of the guide tube between the dry purification room and the main purification room, and the slurry in the main purification room is replaced by spraying industrial water.

[0035] Production line work process of the present invention is as follows:

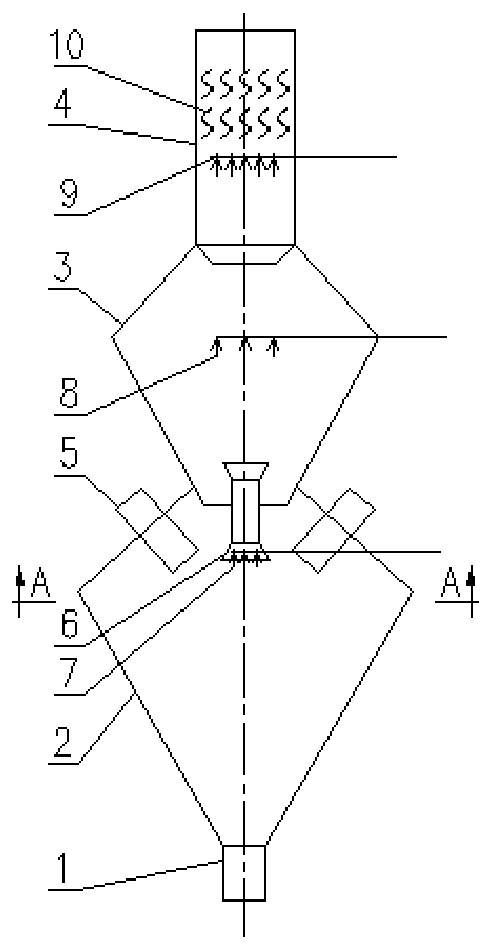

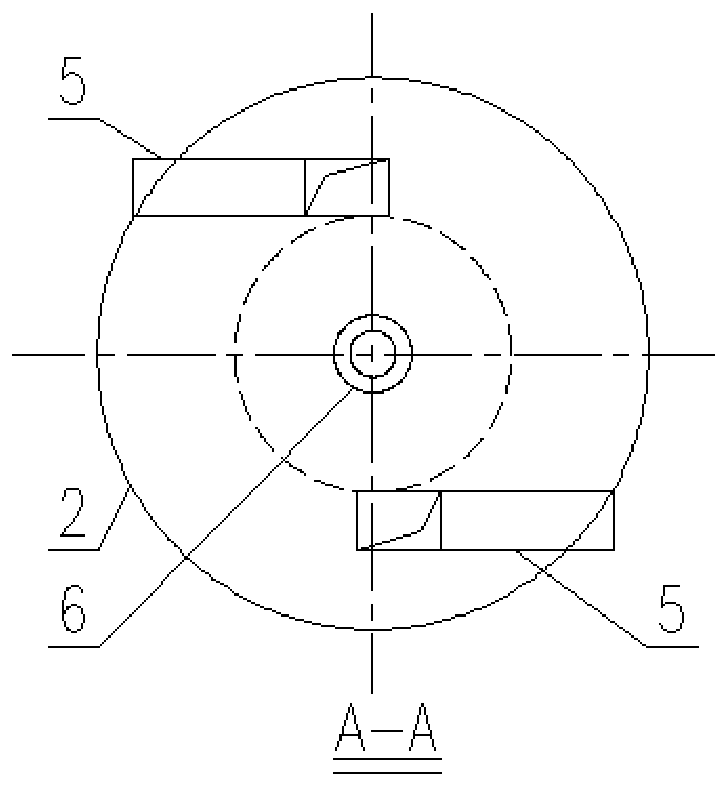

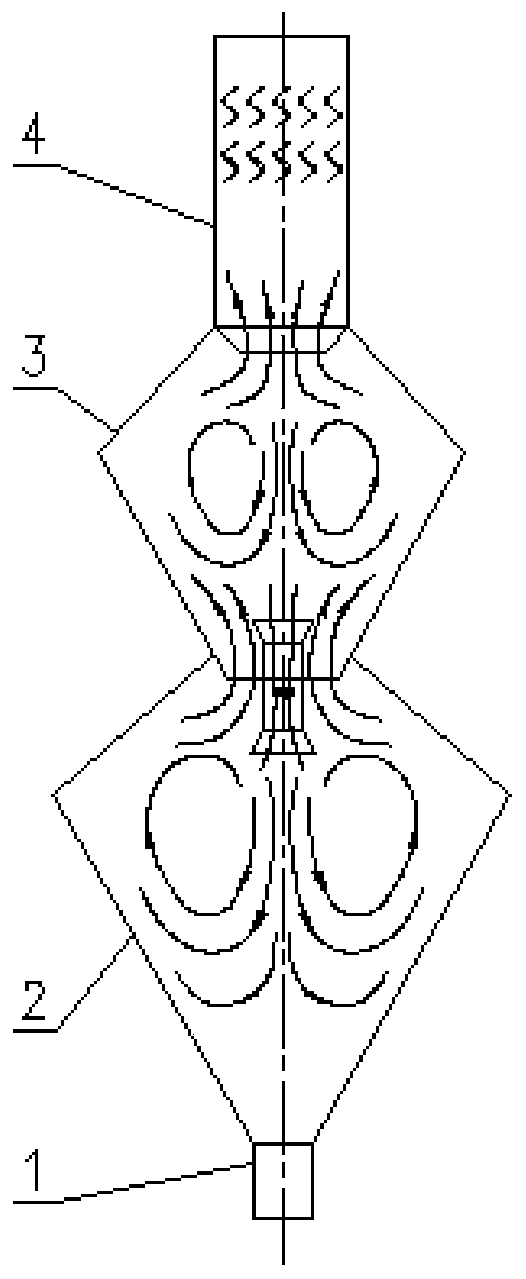

[0036] The flue gas dives in from the upper spandrel of the drying and cleaning room and flows out from the outlet of the spraying and washing room. By rationally designing the shape of the clean room and taking appropriate guiding measures, such as image 3 The flow field shown: the flue gas of the overall purification tower moves from bottom to top and is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com