Preparation method of electrospun fiber scaffold material

An electrospinning and fiber scaffold technology, applied in the field of medical materials, can solve the problems of small pore size and poor degradation performance of materials, and achieve the effects of increasing the scaffold space, enhancing the potential, and broadening the scope of the space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

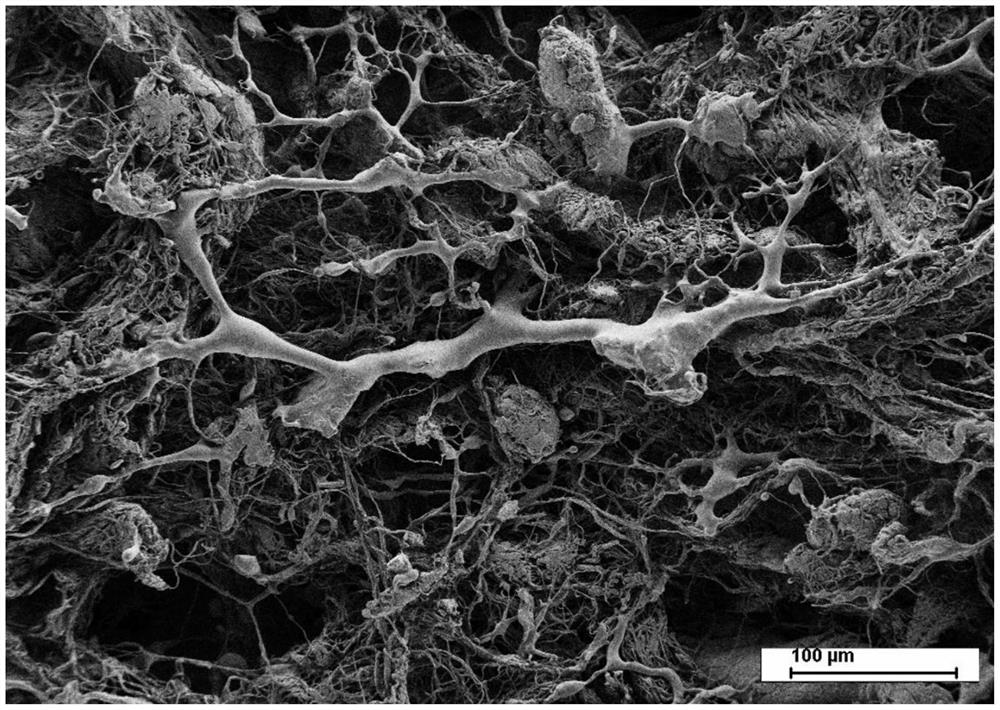

Image

Examples

Embodiment 1

[0031] Step 1. Preparation of basement membrane and stirring and crushing:

[0032] S1, preparing a polylactic acid-glycolic acid copolymer electrospinning chloroform solution with a mass percentage of 2%, and making a nanofiber film with a three-dimensional structure (also called electrospinning) by electrospinning the electrospinning solution fiber membrane), the electrospinning conditions are: voltage 5kV, receiving distance 6cm, sample injection speed 0.5mL / h;

[0033] S2. Preliminary experiment: Scissors cut 4g poly(lactic acid-glycolic acid copolymer) electrospun fiber membrane, add it to the centrifuge tube according to the design, and add Tris-HCl solution;

[0034] S3. Stir with a high-speed stirrer in the centrifuge tube (control the stirring speed to 1200r / h, stir for 2 minutes), stir and smash until completely slurryed.

[0035] Step 2, preparation of cross-linking solution:

[0036] S1. Prepare a PEI-dopamine solution with a weight ratio of 1.8% (the weight rati...

Embodiment 2

[0043] About PEI Concentration

[0044] Cross-linking electrospun fiber membranes with different concentrations of PEI-dopamine solutions

[0045] Step 1. Preparation of basement membrane and stirring and crushing:

[0046] S1, preparing a polylactic acid-glycolic acid copolymer electrospinning dimethylformamide solution with a mass percentage of 3%, and making the electrospinning solution into a nanofiber film with a three-dimensional structure (also known as Electrospun fiber membrane), the electrospinning conditions are: voltage 13kV, receiving distance 12cm, sample injection speed 2mL / h;

[0047] S2. Preliminary experiment: cut 3-5g electrospun fiber membrane with scissors, put it into a centrifuge tube according to the design, and add Tris-HCl solution.

[0048] S3. Stir with a high-speed mixer in a centrifuge tube (control the stirring speed to 1000r / h, and stir for 4 minutes), stir and crush until completely slurryed.

[0049] Step 2, preparation of cross-linking solut...

Embodiment 3

[0058] About PEI Crosslinking Sequence

[0059] Step 1, preparation of 5% polylactic acid-glycolic acid copolymer (PLGA) and polycaprolactone (PCL) electrospinning trifluoroethanol solution, and the electrospinning solution is made by electrospinning Nanofiber film with three-dimensional structure (also known as electrospun fiber film), the electrospinning conditions are: voltage 19kV, receiving distance 20cm, sample injection speed 3.5mL / h;

[0060] Break 3-5g of poly(lactic-co-glycolic acid) and polycaprolactone (PCL) film in Tris-Hcl (pH=8.5%) solution (control the stirring speed to be 1200r / h), stir for 2 minutes, until broken into pulp.

[0061] Step 2, preparing 0.5% PEI-dopamine (DA) cross-linking solution:

[0062] S1. Measure 10ml Tris-Hcl into 2 watch glasses, respectively add 2 parts of 0.02g dopamine into the watch glasses, and dissolve completely.

[0063] S2. Weigh 0.05g of PEI into the watch glass and dissolve it completely.

[0064] Step 3: Add the cross-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com