Multi-automobile-type stamping part rapid carrying equipment and multi-automobile-type mixed production line

A technology for handling equipment and multiple models. It is applied in the directions of conveyor objects, transportation and packaging, and manipulators. It can solve problems such as non-conformity and slow efficiency, achieve high precision, expand space range, and improve the effect of handling rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

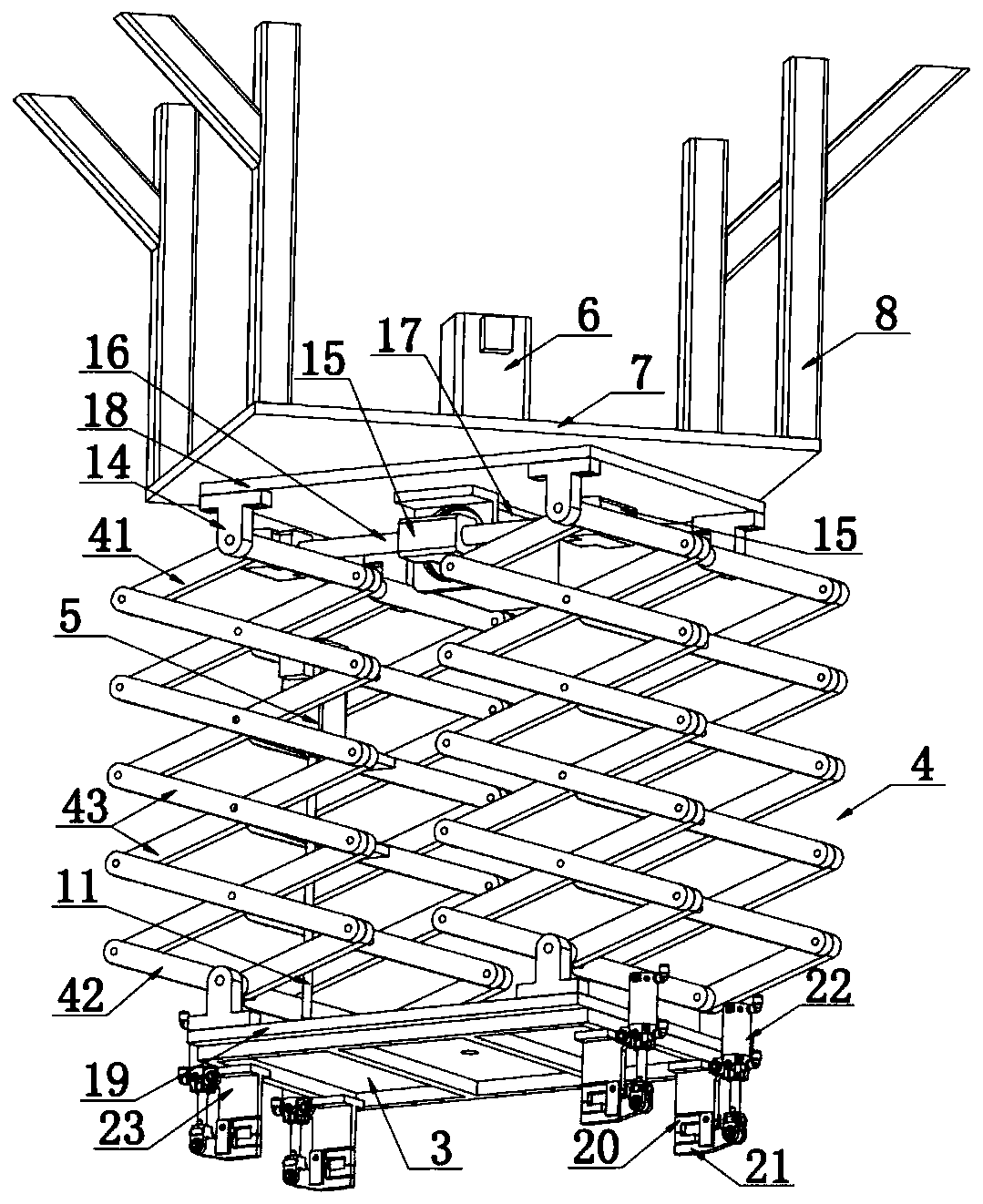

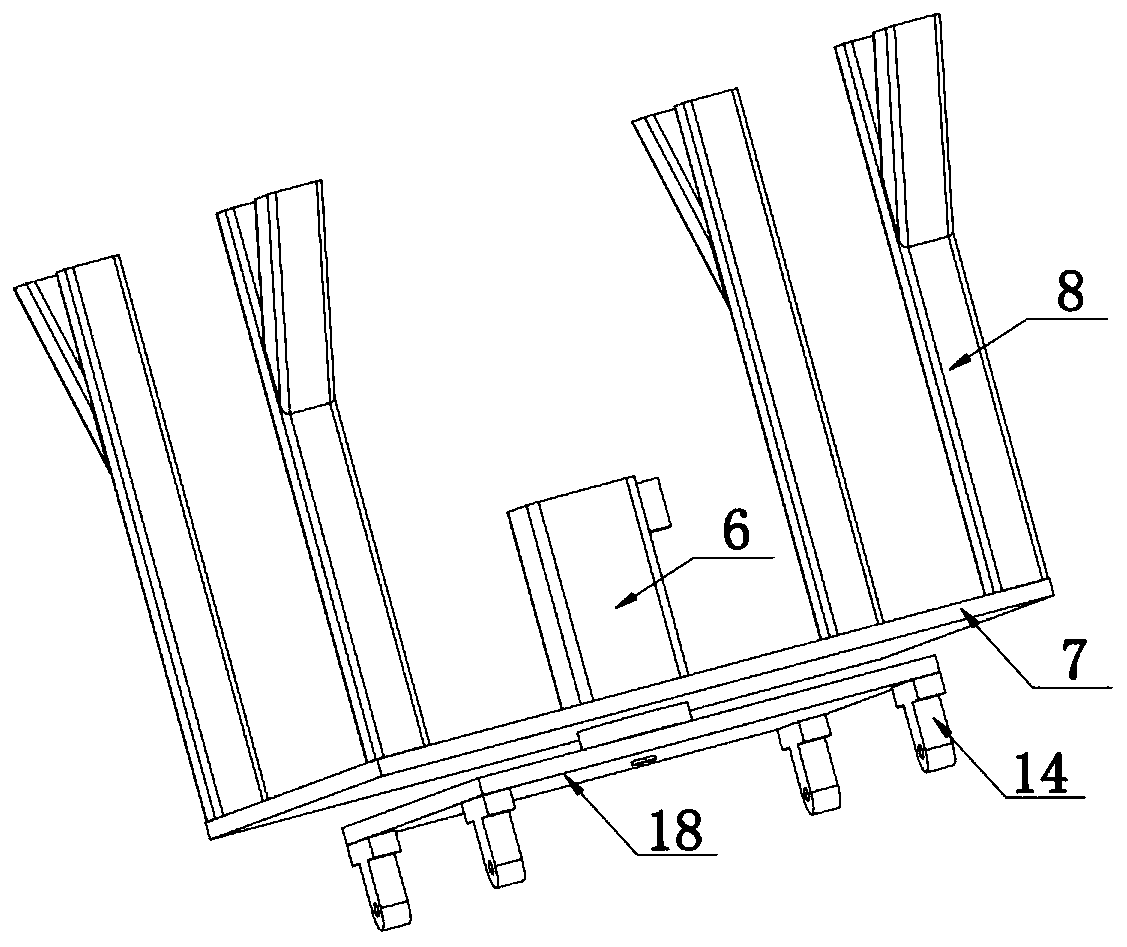

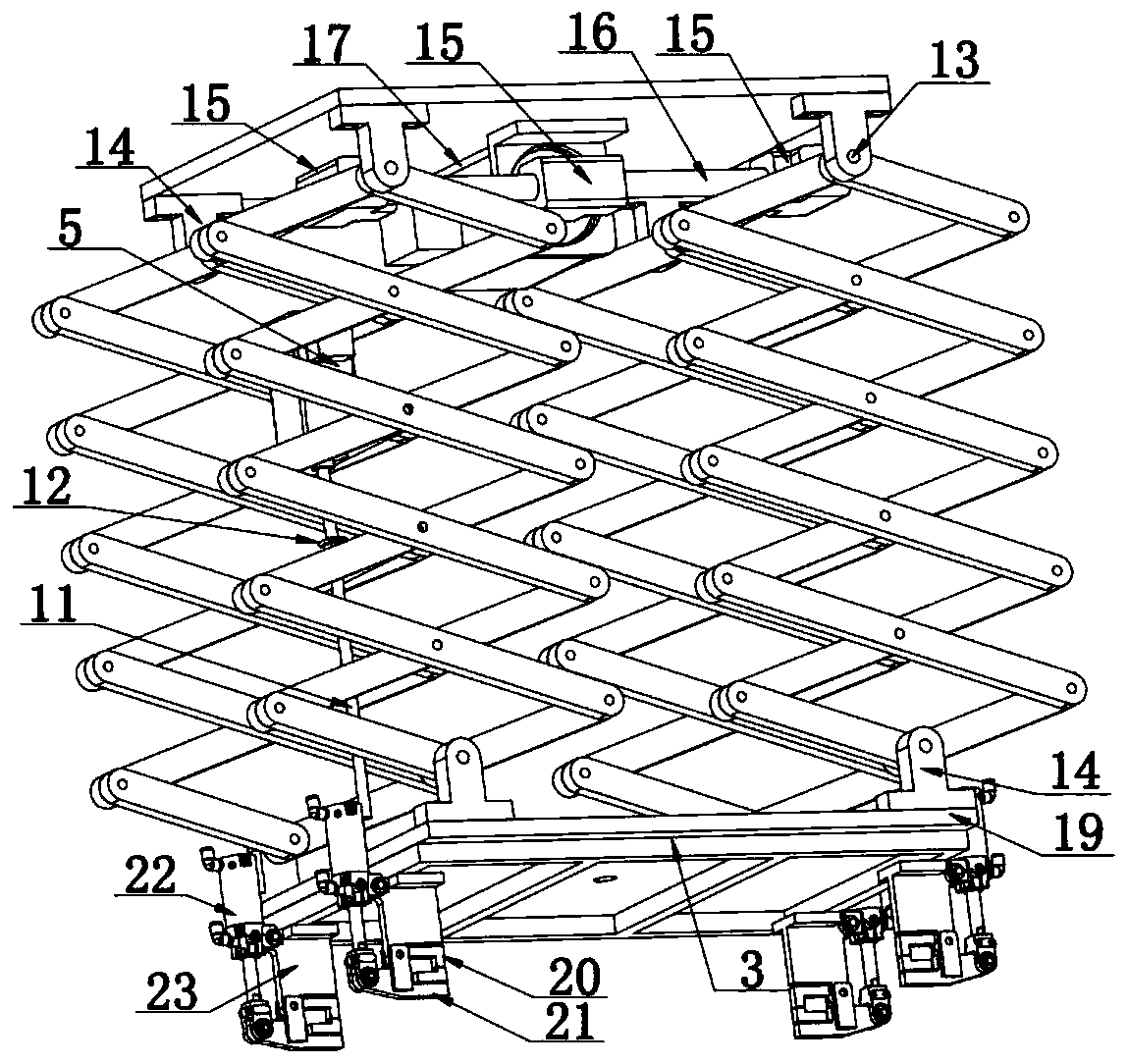

[0039] Such as Figure 1-Figure 4 As shown, a multi-vehicle stamping parts rapid handling equipment includes a rotating mechanism, a swing mechanism arranged at the bottom of the rotating mechanism, and a gripper mechanism arranged at the bottom of the swing mechanism. The rotating mechanism includes a fixed platform 7 and is arranged on the fixed platform. The rotating servo motor 6;

[0040] The swing mechanism includes a swing top 18, a swing bottom plate 19, left and right scissor rocker mechanisms arranged between the swing top plate and the swing bottom plate, a swing drive mechanism for driving the swing of the scissor rocker mechanism, and a A telescopic drive mechanism that drives the scissor rocker mechanism to expand and contract, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com