Portable industrial robot based on multi-dimensional sensor real-time data feedback fusion

An industrial robot, real-time feedback technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., to achieve the effect of reducing production costs, high flexibility, and high load strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

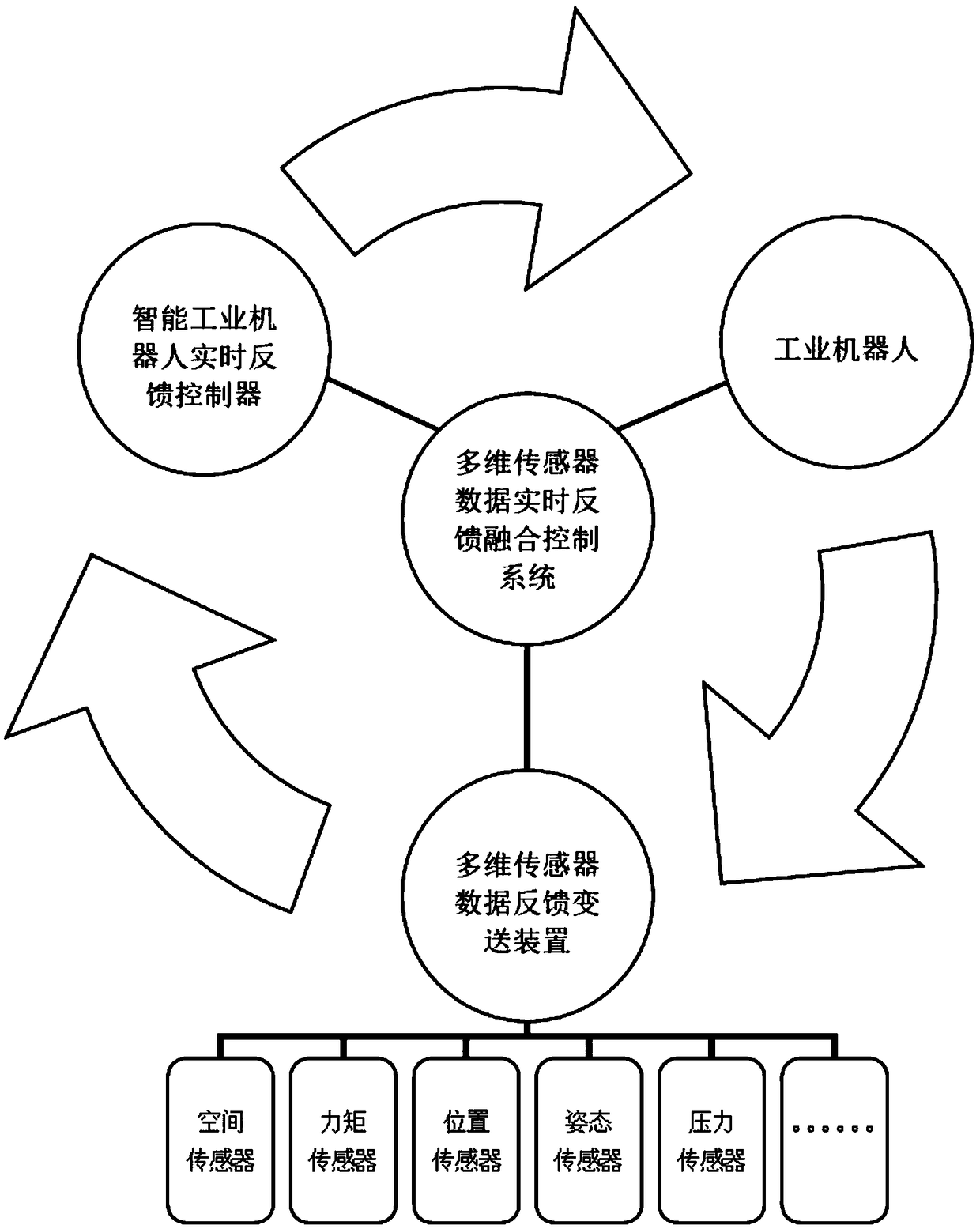

[0034] Referring to the accompanying drawings: the portable industrial robot based on multi-dimensional sensor real-time data feedback fusion in this embodiment includes a multi-dimensional sensor data real-time feedback fusion control system, and the multi-dimensional sensor data real-time feedback fusion control system is connected with industrial robots, Intelligent industrial robot real-time feedback controller, multi-dimensional sensor data feedback transmission device, industrial robot, intelligent industrial robot real-time feedback controller, multi-dimensional sensor data feedback transmission device form multi-dimensional sensor data real-time feedback fusion control system through multi-dimensional sensor data real-time feedback Feedback Fusion Control.

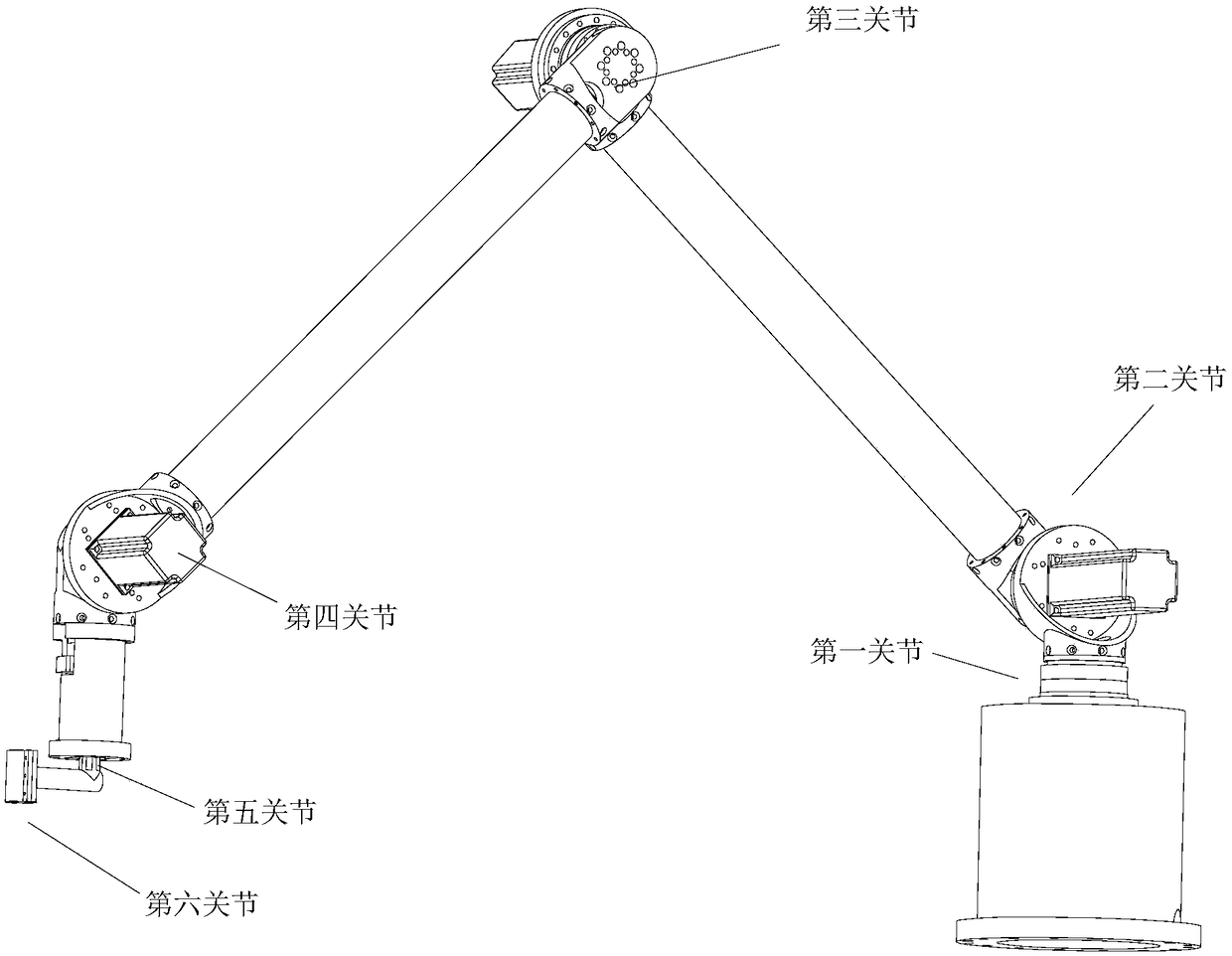

[0035] The industrial robot includes a robot body structure with no less than three movable joints, among whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com