Laver double-sided dye seasoning machine

A seasoning machine and seaweed technology, applied in food science, food coating, application and other directions, can solve the problems of low production efficiency, uneven distribution, unable to meet the processing requirements of multi-layer sandwiched seaweed, etc., and achieve high production efficiency and contamination. The uniform effect of the seasoning liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

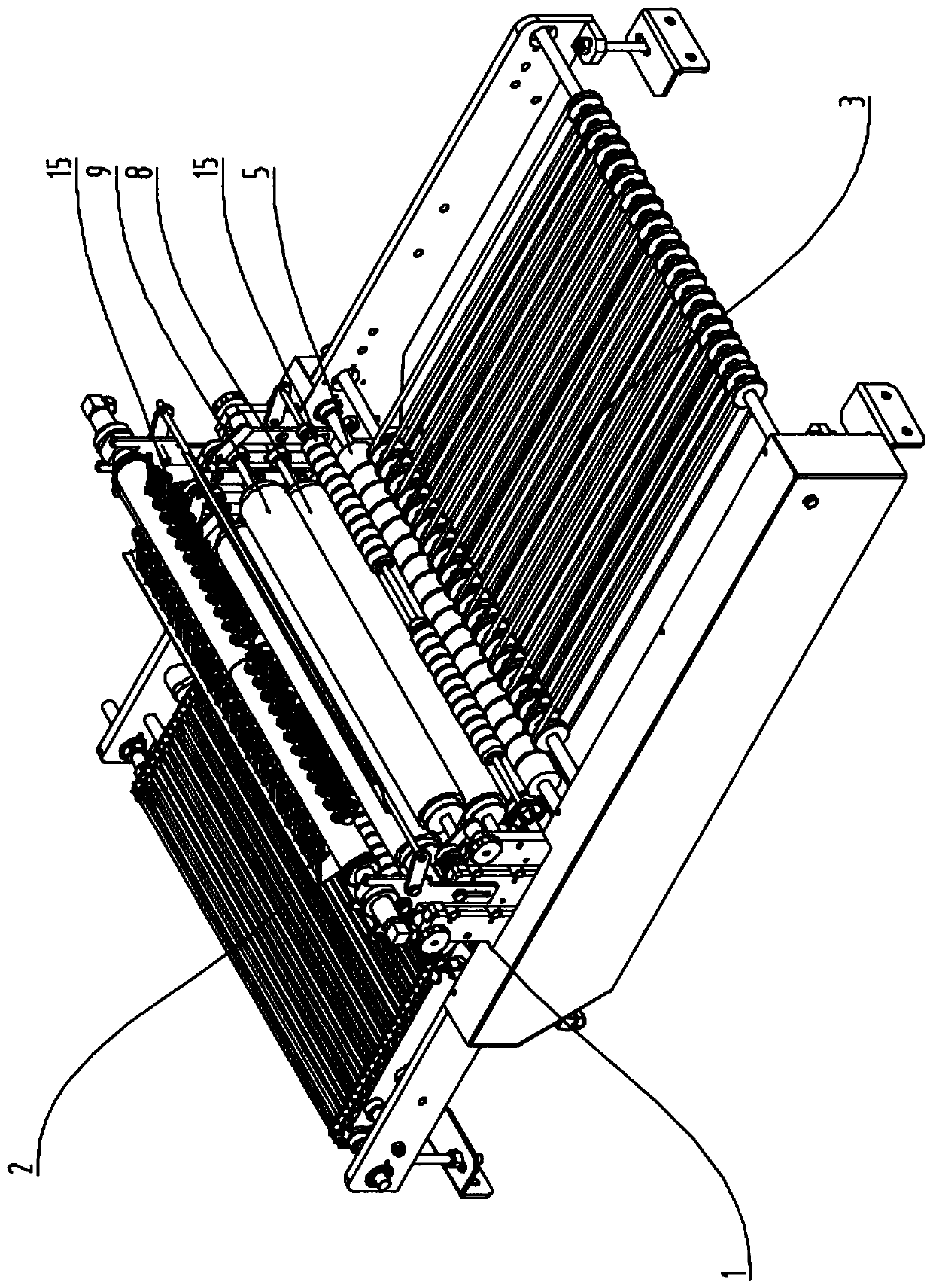

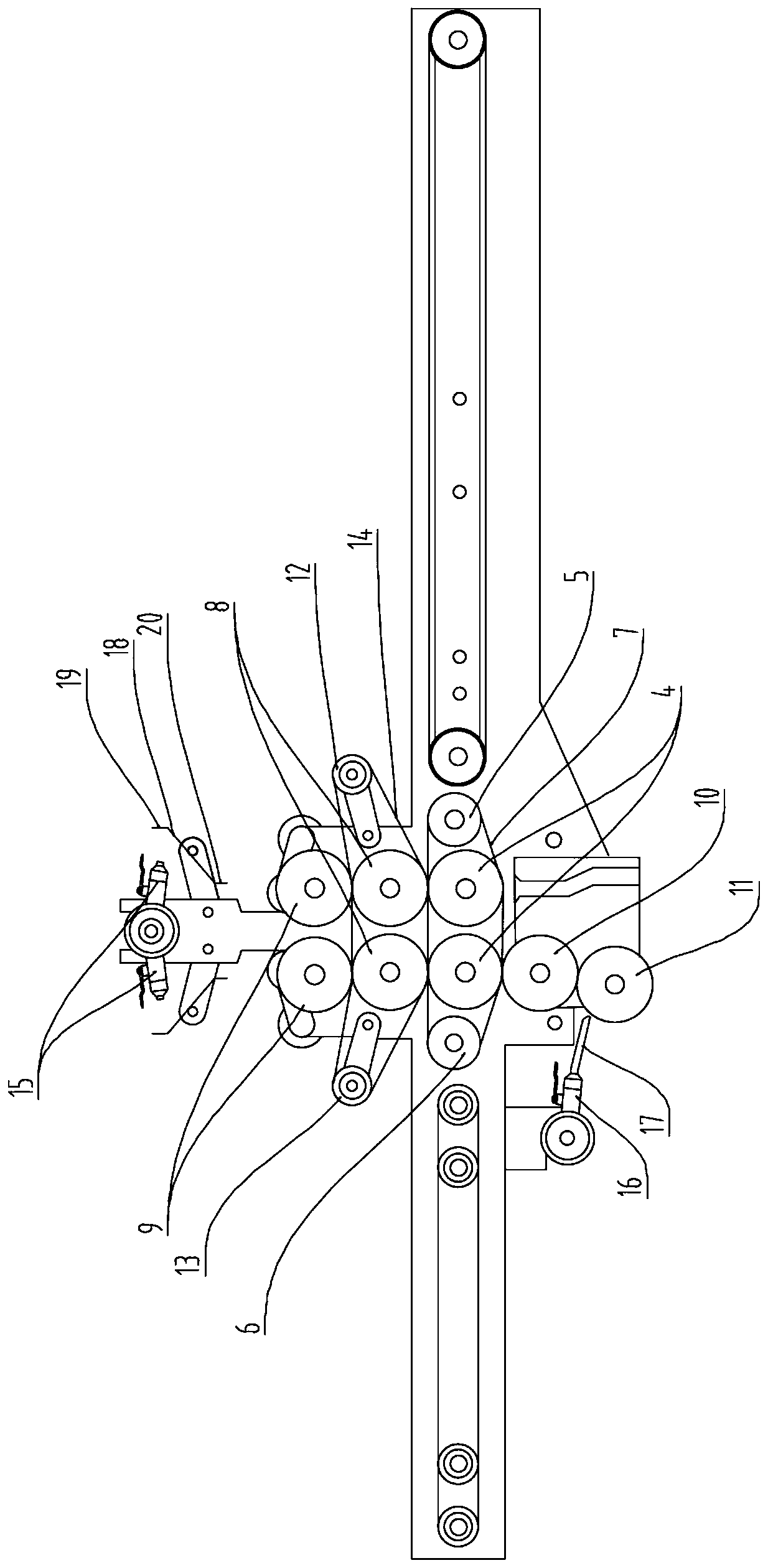

[0035] refer to figure 1 , combined with figure 2 , laver double-sided dye seasoning machine, comprising frame 1, is provided with horizontal conveyer belt on frame 1; Described conveyer belt comprises laver feed conveyer belt 2 and laver discharge conveyer belt 3, in laver feed conveyer belt 2 and laver discharge conveyor belt 3 are provided with seasoning sponge roller group;

[0036]Described seasoning sponge roller group comprises the double-sided infectious sponge roller 4 that is located between laver feeding conveyer belt 2 and laver discharge conveyer belt 3, double-sided contagious sponge roller 4 is parallel to the transmission plane of conveyer belt and with the conveyer belt The transmission direction is set vertically;

[0037] Between the laver feeding conveyor belt 2 and the laver discharging conveyor belt 3 and being positioned at the front and rear sides of the double-sided infected sponge roller 4, the first transmission line roller 5 and the second convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com