Nitrogen-doped hollow spherical carbon-coated sulfur cathode material and its preparation method and application

A spherical carbon-encapsulated, nitrogen-doped technology, used in nanotechnology for materials and surface science, positive electrodes, electrode manufacturing, etc., can solve the problems of short cycle life, poor cycle stability, etc., to improve cycle life, excellent The effect of high current charging and discharging and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

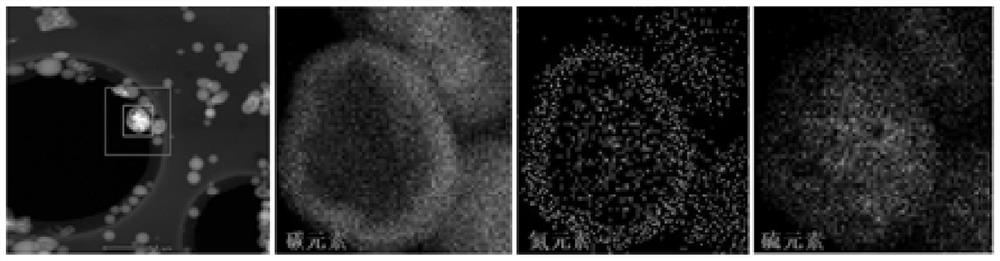

[0050] The preparation of the nitrogen-doped hollow spherical carbon-coated sulfur material specifically includes the following steps:

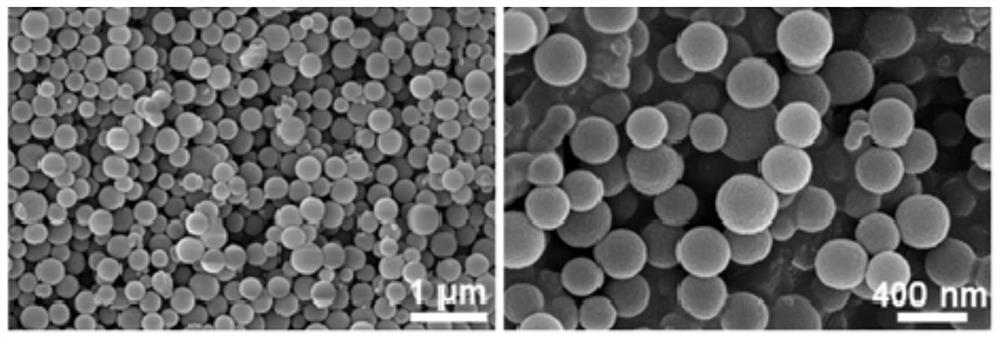

[0051] Step 1: Preparation of nitrogen-doped hollow spherical carbon materials

[0052] (1) According to the mass ratio of dopamine hydrochloride and F127 ethylene glycol with a molecular weight of 8000-10000 as 3:5, feed and mix to obtain solid mixture A; according to dopamine hydrochloride, 1,3,5-trimethylbenzene and alcohol / water The mass ratio of the mixed solution is 1:1.6:10 and weighed for later use, wherein the mixed solution of alcohol / water is prepared according to the mass ratio of 1:1; The mixed solution of methylbenzene and alcohol / water is stirred on a magnetic stirrer to allow it to be fully and evenly mixed to obtain a mixed solution B;

[0053] (2) Calculate and measure according to the mass ratio of dopamine hydrochloride and saturated ammonia water as 1:1.5, add the measured ammonia water to the mixed solution B, and the p...

Embodiment 2

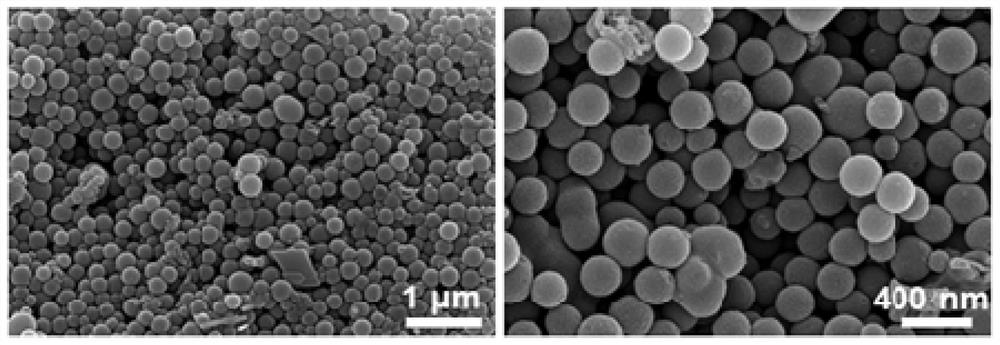

[0062] The preparation of the nitrogen-doped hollow spherical carbon-coated sulfur material specifically includes the following steps:

[0063] Step 1: Preparation of nitrogen-doped hollow spherical carbon materials

[0064] (1) According to the mass ratio of dopamine hydrochloride and F127 ethylene glycol with a molecular weight of 10000-20000 as 3:4.5, feed and mix to obtain solid mixture A; The mass ratio of the mixed solution composed at a mass ratio of 1:1 is 1:1.8:5.5 to be weighed for later use, and the mixture of 1,3,5-trimethylbenzene and alcohol / water weighed above is sequentially added to the solid mixture A. solution, stirred on a magnetic stirrer to allow it to fully and evenly mix to obtain a mixed solution B;

[0065] (2) Calculate and take according to the mass ratio of dopamine hydrochloride and saturated ammonia water as 1:1.6, add the ammonia water measured in the mixed solution B, and the polymerization reaction time is 50 minutes; then collect the suspend...

Embodiment 3

[0075] The preparation of the nitrogen-doped hollow spherical carbon-coated sulfur material specifically includes the following steps:

[0076] Step 1: Preparation of nitrogen-doped hollow spherical carbon materials

[0077](1) According to the mass ratio of dopamine hydrochloride and F127 ethylene glycol with a molecular weight of 10000-20000 as 3:3, feed and mix to obtain a solid mixture A; The mass ratio of the mixed solution composed at a mass ratio of 1:1 is 1:1.5:8 and weighed for later use, and the mixture of 1,3,5-trimethylbenzene and alcohol / water weighed above is sequentially added to the solid mixture A. solution, stirred in an electric mixer to allow it to be fully and evenly mixed to obtain a mixed solution B;

[0078] (2) Calculate and take according to the mass ratio of dopamine hydrochloride and saturated ammonia water as 1:1.3, add the ammonia water measured in the mixed solution B, and the polymerization reaction time is 70 minutes; then collect the suspende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com