High-resolution hard X-ray tungsten/gold Fresnel zone plate and preparation method thereof

A high-resolution, X-ray technology, applied in radiation/particle processing, application of diffraction/refraction/reflection for processing, nanotechnology, etc., can solve the problem that the outermost ring width of the zone plate and the large aspect ratio cannot be taken into account. , to achieve the effect of improving the success rate of sample preparation, reducing the cost, and improving the etching selection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of high-resolution hard X-ray tungsten / gold Fresnel zone plate by etching method

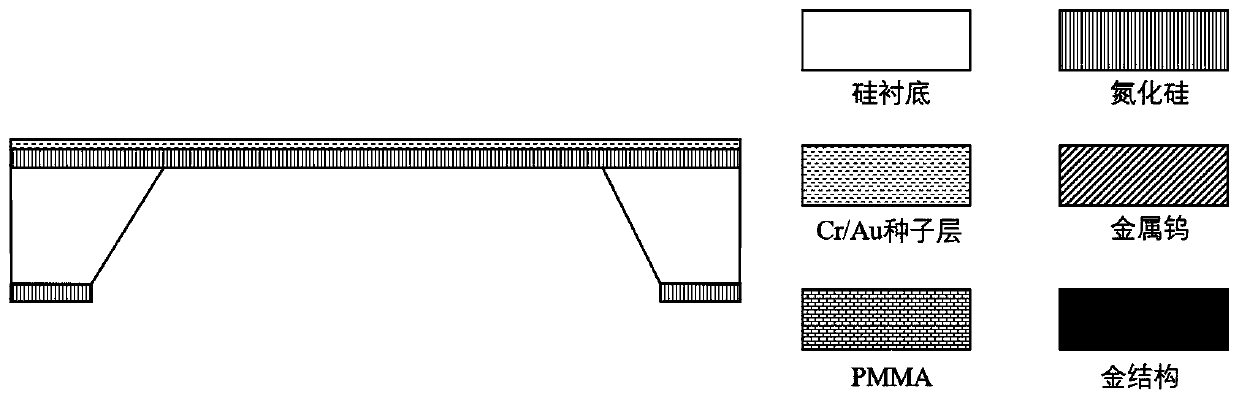

[0047] (1) Select the silicon nitride diaphragm base material with a thickness of 100nm. A 5nm / 15nm Cr / Au layer is deposited on the substrate by physical vapor deposition as a conductive metal layer. The result is as figure 1 shown;

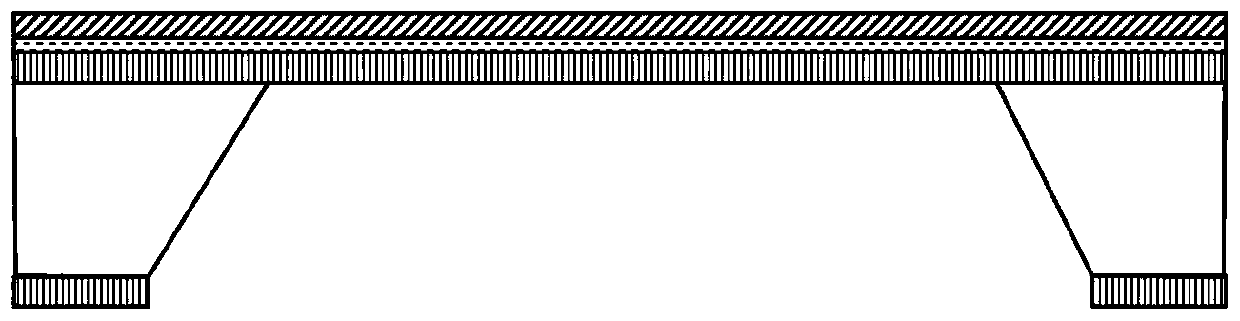

[0048] (2) On the seed layer, a 300nm metal tungsten film is deposited by PVD. The result is as figure 2 shown;

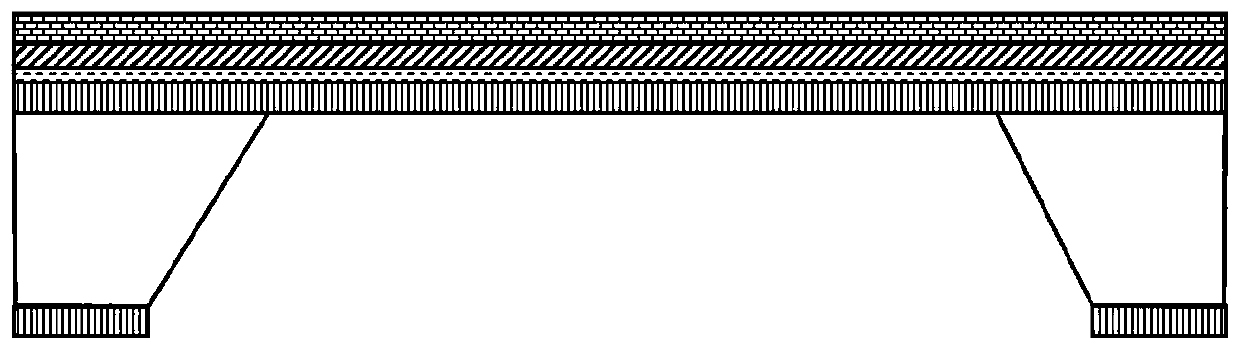

[0049] (3) Spin-coat a layer of HMDS on the front side of the substrate with a metal layer as an adhesion layer, then spin-coat a 250nm PMMA photoresist, and bake it at 180°C for 1 hour. The result is as image 3 shown;

[0050] (4) Expose the sample under the electron beam exposure machine, develop the exposed sample with 1:3 MIBK and IPA, the time is 1.5 minutes, the development temperature is 23°C; and wash in IPA for 30 seconds. The result is as Figure 4 shown;

[0051] (5) Electroplate Au on the surface o...

Embodiment 2

[0054] Example 2: Preparation of high-resolution hard X-ray tungsten / gold Fresnel zone plate by etching method

[0055] (1) Select the silicon nitride diaphragm base material with a thickness of 100nm. A 10nm / 15nm Ti / Au layer is deposited on the substrate by physical vapor deposition as a conductive metal layer. The result is as Figure 8 shown;

[0056] (2) On the seed layer, a 300nm metal tungsten film is deposited by PVD. The result is as Figure 9 shown;

[0057] (3) Spin-coat a layer of HMDS on the front side of the substrate with a metal layer as an adhesion layer, then spin-coat a 250nm PMMA photoresist, and bake it at 180°C for 1 hour. The result is as Figure 10 shown;

[0058] (4) Expose the sample under the electron beam exposure machine, develop the exposed sample with 1:3 MIBK and IPA, the time is 1.5 minutes, the development temperature is 23°C; and wash in IPA for 30 seconds. The result is as Figure 11 shown;

[0059] (5) Electroplate Au on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com