Full-automatic test calorimeter and test method

A fully automatic test and test method technology, applied in the field of sample testing, can solve the problems of interference with experimental results, low degree of automation, and high labor intensity, and achieve the effects of high test accuracy, high degree of automation, and avoiding gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

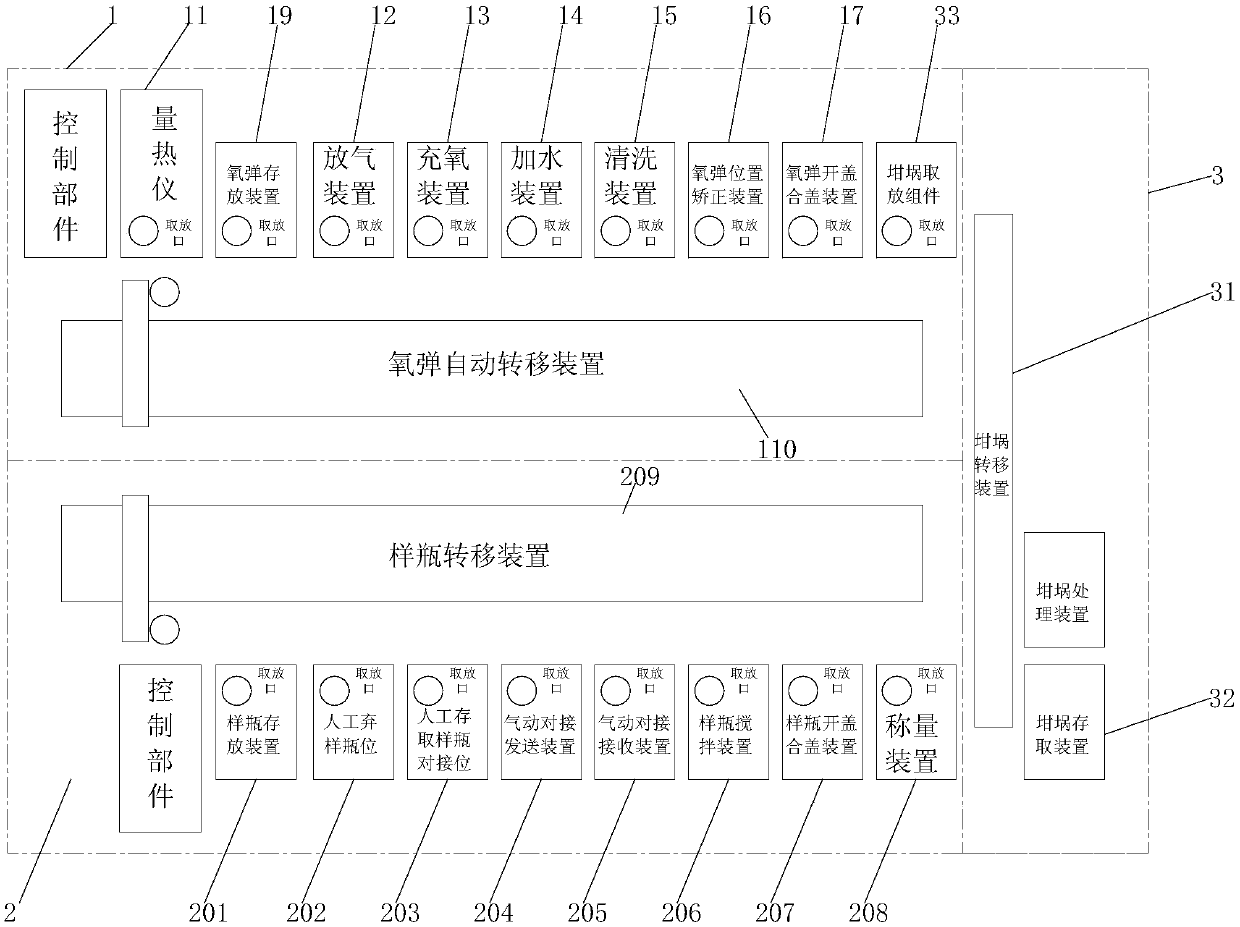

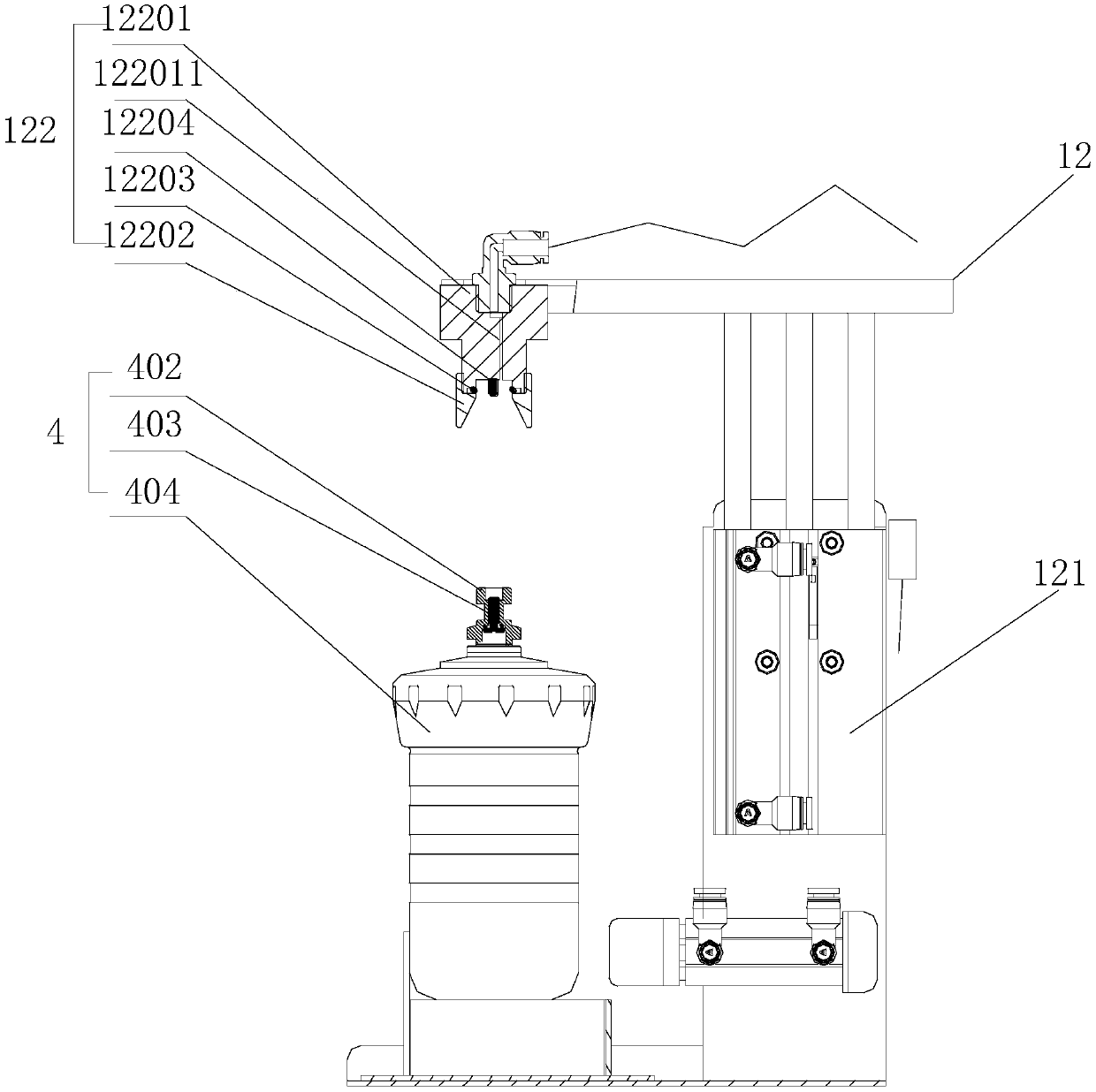

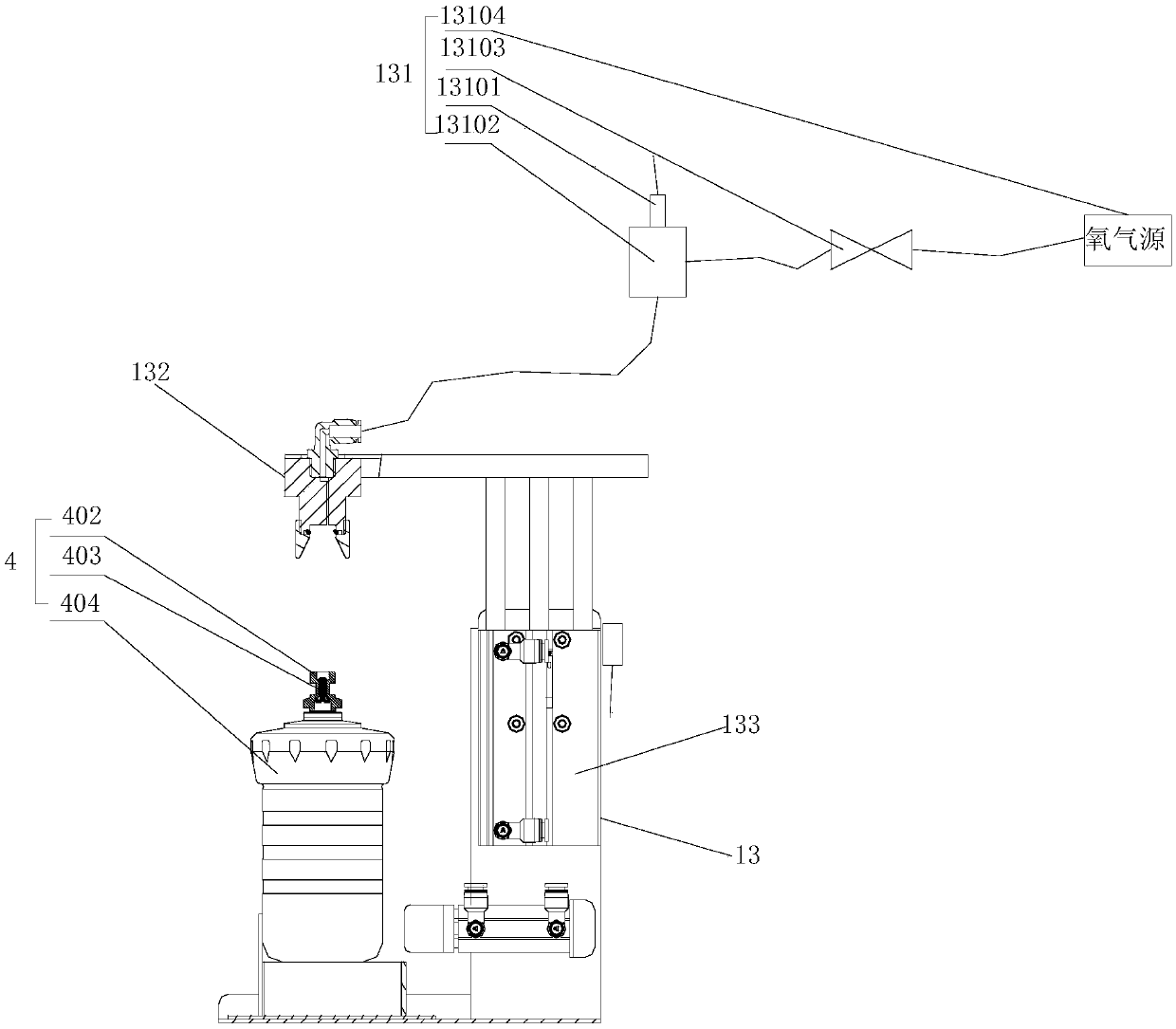

[0078] like figure 1 As shown, the fully automatic test calorimeter of this embodiment includes an oxygen bomb processing and testing module 1, a sample bottle processing and weighing module 2, and a crucible access and transfer module 3; wherein the sample bottle processing and weighing module 2, It is used to process the sample bottle and weigh the specified weight sample into the crucible; the crucible access and transfer module 3 includes the crucible transfer module 31, which is used to transfer the weighed crucible from the sample bottle processing and weighing module 2 to Oxygen bomb processing and testing module 1; oxygen bomb processing and testing module 1 is used to process the oxygen bomb and place the weighed crucible in the oxygen bomb for calorific value testing. The automatic test calorimeter of the present invention realizes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com