Raft foundation building lifting and reinforcing structure and method under corrosive geological environment

A raft foundation and geological environment technology, applied in the direction of basic structure engineering, construction, protection devices, etc., to improve the quality of grouting, avoid water erosion, and improve the overall bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

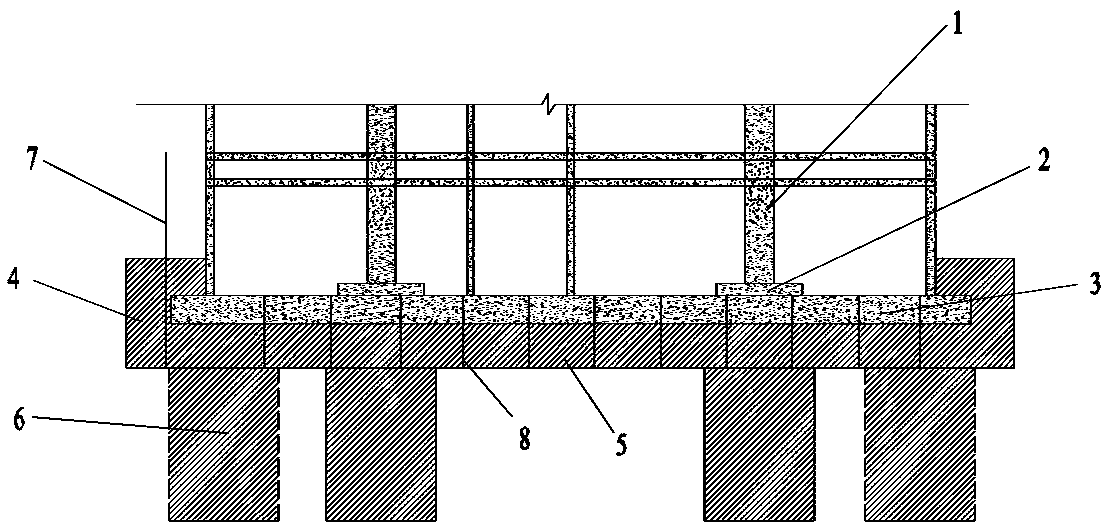

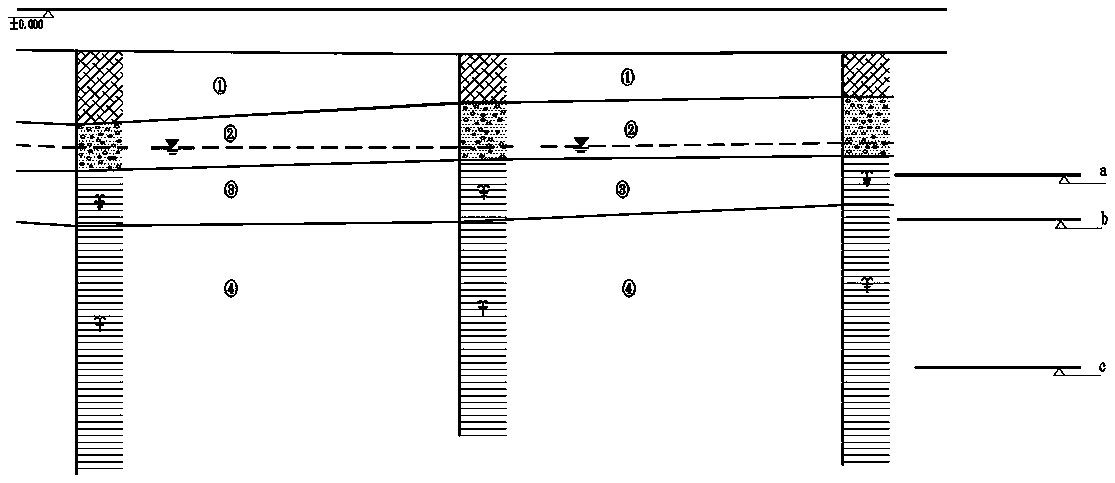

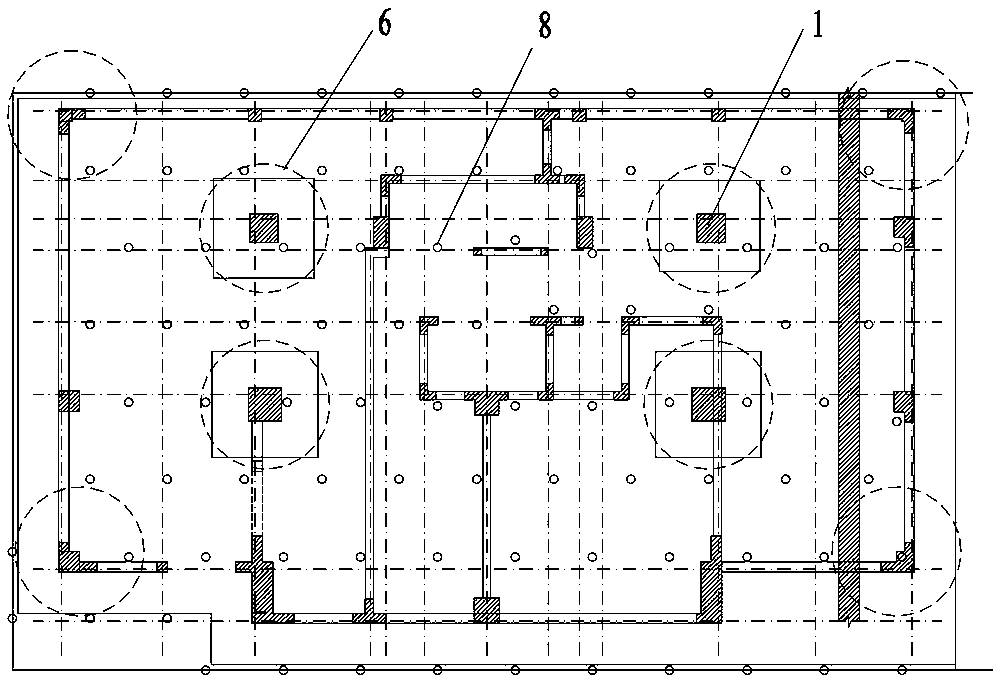

[0038] Taking a high-rise building on the Bund as an example, the structure of the building is one floor underground, the ground is divided into 28 floors and 24 floors, and 4 floors of the podium, among which 300mm expansion joints are set between the 28th floor and the 24th floor, and 100mm between the 24th floor and the podium. expansion joints. The structure of the 28-story building is a frame-supported shear wall. The building is about 30m long, 20m wide, and 90m high. The foundation is a flat raft foundation. The thickness of the raft foundation 3 is 1300mm, and the base elevation is -7.80m.

[0039] Under the monitoring of the original observation point, the 28-story building has subsided, and the cumulative settlement is 5-10mm. To prevent further subsidence of the building, it needs to be lifted and reinforced. After preliminary investigation and investigation, the raft foundation 3 of this building is placed in a strongly weathered mudstone layer, and the rock mass i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com