Suspension-arm-type hot metal ladle tipping-over iron charging device

A molten iron tank and molten iron technology, which is applied in the field of construction of iron mixing furnaces, can solve problems such as splashing and pollution of furnace water and molten steel, and reduce the operation efficiency of electric furnaces, and achieve the effects of reducing the amount of smoke and dust, improving operation efficiency and ensuring normal production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

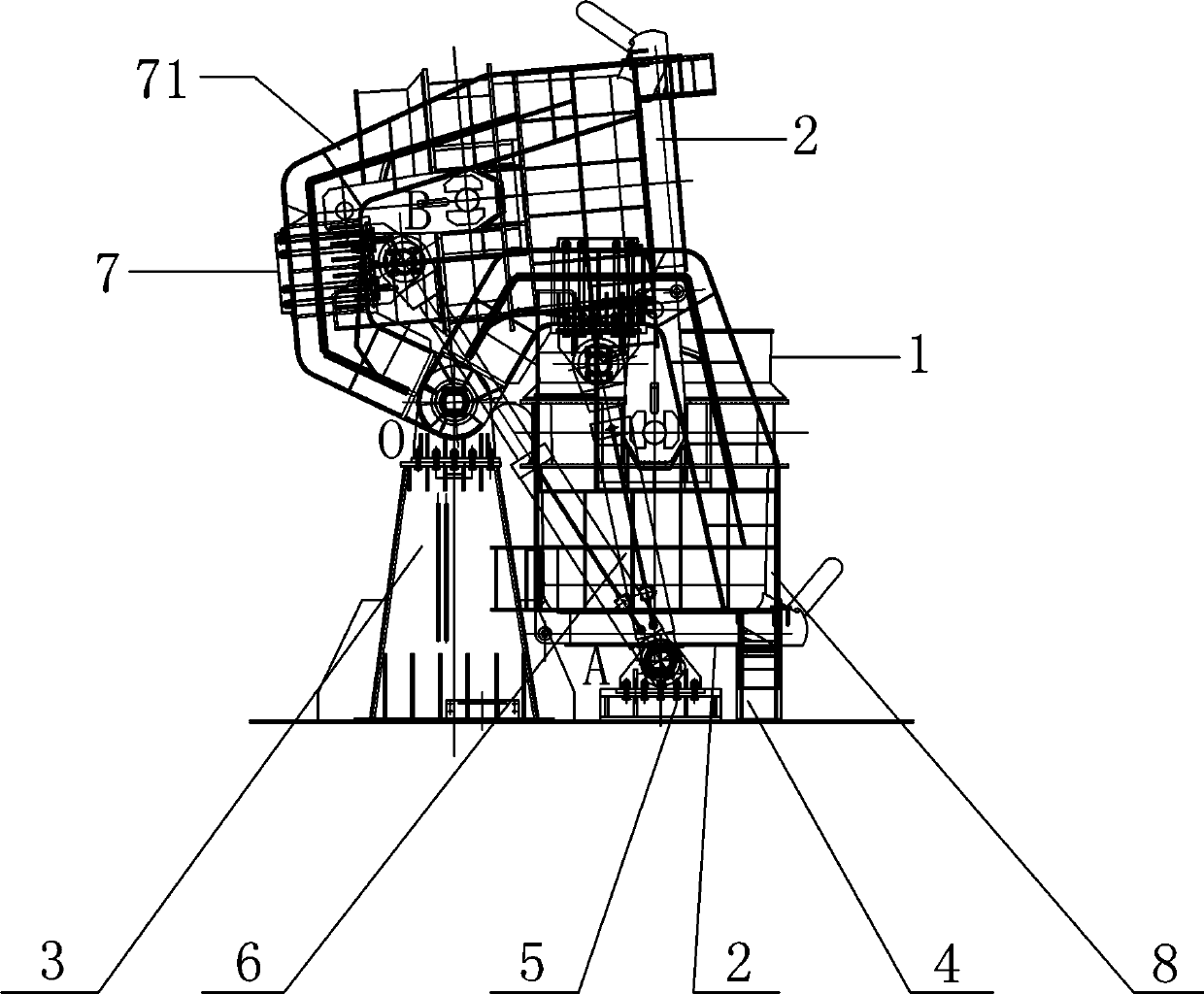

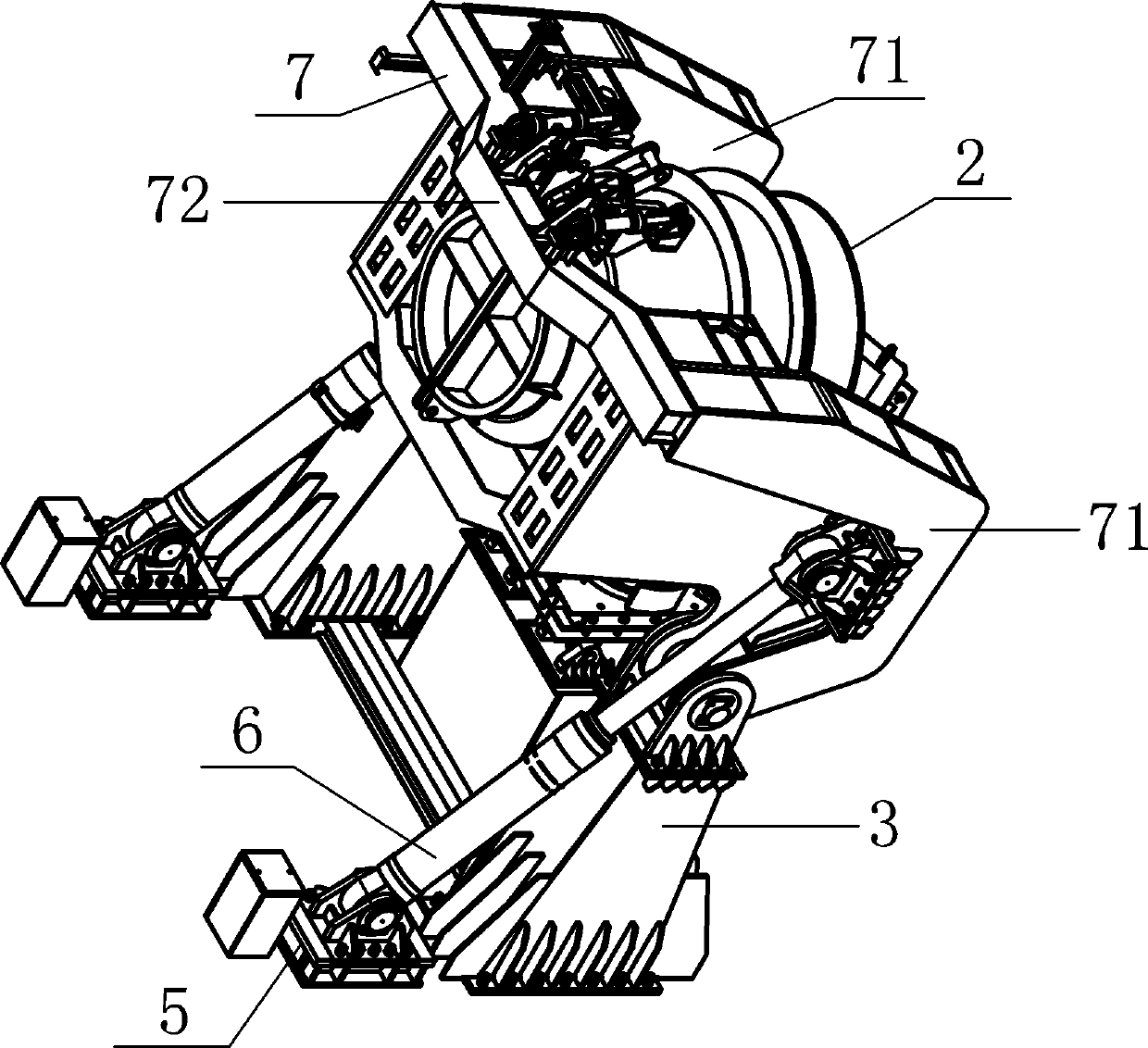

[0022] A crane arm type molten iron tank tipping iron mixing device, including an electric furnace 1, a molten iron tank 2, legs 3, a fixed seat 4, a hydraulic cylinder base 5, a hydraulic cylinder 6, a tilting frame 7 and a tilting frame support 8 ,Such as figure 1 and figure 2 As shown, the specific structure is:

[0023] The two supporting legs 3 are arranged oppositely and fixed on the ground, and the electric furnace 1 is arranged on the ground between the two supporting legs 3;

[0024] Both sides of each supporting leg 3 are respectively provided with a fixed seat 4 and a hydraulic cylinder base 5, and the cylinder body of a hydraulic cylinder 6 is respectively fixed on each hydraulic cylinder base 5, and the tipping frame 7 includes a curved arm 71 and a tilting Rod 72, the inner ends of two curved arms 71 are respectively rotatably arranged on the top of a support leg 3 through bearings, and the two ends of tilting rod 72 are respectively connected with the outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com