Oil-resistant and high-temperature-resistant ship cable

A high-temperature-resistant, naval ship technology, applied in the field of ship cables, can solve the problems of silicone rubber tensile strength, insulation performance and wear resistance decline, insulation layer corrosion damage, ship operation instability, etc., to reduce the aging speed, Retains the effect of oil resistance and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

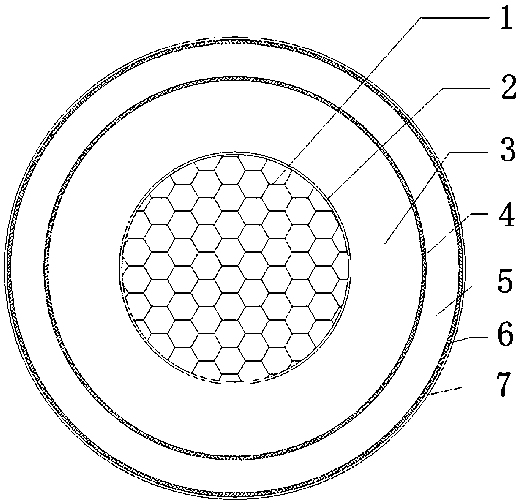

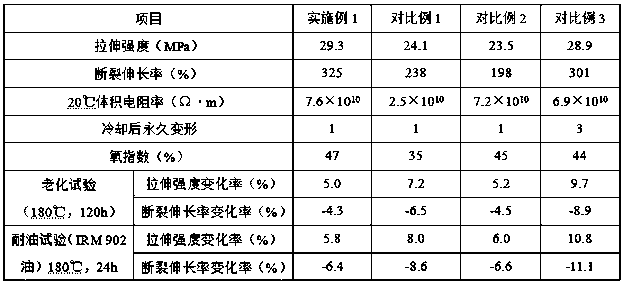

[0025] An oil-resistant and high-temperature-resistant naval cable, from the inside to the outside is a conductor 1, a tape layer 2, an insulating layer 3, a fiber braided reinforcement layer 4, a sheath 5, a glass fiber braided layer 6, and a coating layer 7, wherein The conductor is a tinned copper conductor that is first divided into strands and then multi-stranded and twisted. The wrapping layer is a low-smoke halogen-free flame-retardant tape, and the glass fiber braiding layer is a glass fiber braiding layer after soaking in a silane coupling agent and drying. , The insulating layer and the sheath are all silicone rubber.

[0026] Among them, the insulating layer includes the following components by mass: 80 parts of fluorosilicone rubber, 20 parts of No. 2 fumed silica, 3 parts of nano tin oxide, 2 parts of praseodymium oxide, 3 parts of methylphenyldiethoxysilane, hydroxyl 3 parts of fluorosilicone oil, 5 parts of mica powder, 5 parts of talcum powder, 5 parts of benzo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com