Directly-formed high-air-permeability polyurethane insole composite material and preparation method thereof

A breathable polyurethane technology, applied in the field of polyurethane, can solve the problems of formula composition and air permeability data that have not been seen to improve air permeability, and achieve the effects of industrial production, enhanced air permeability, and improved porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

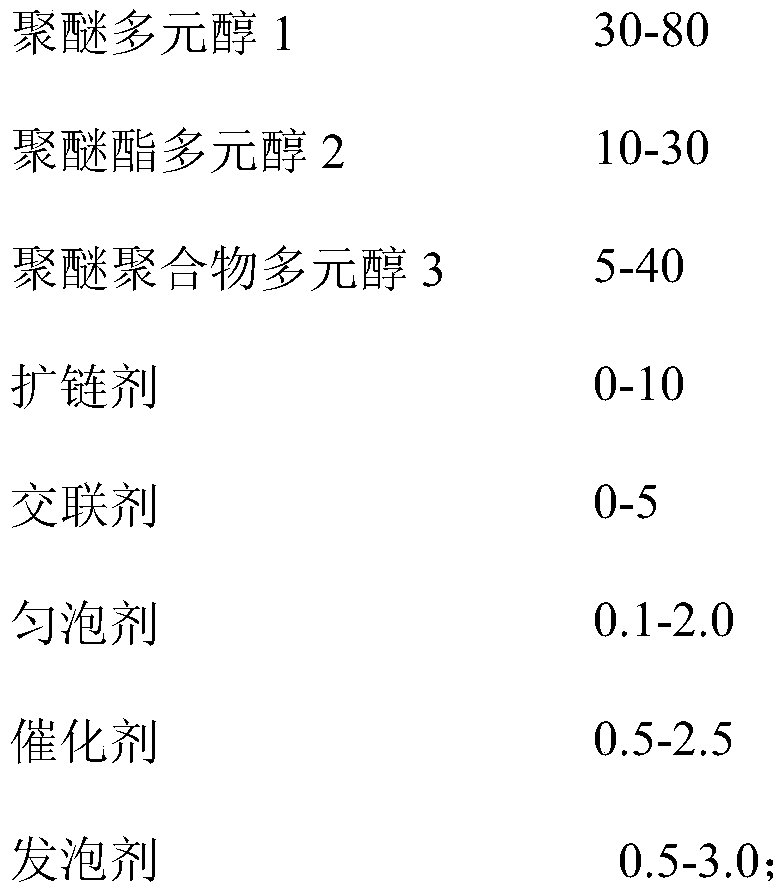

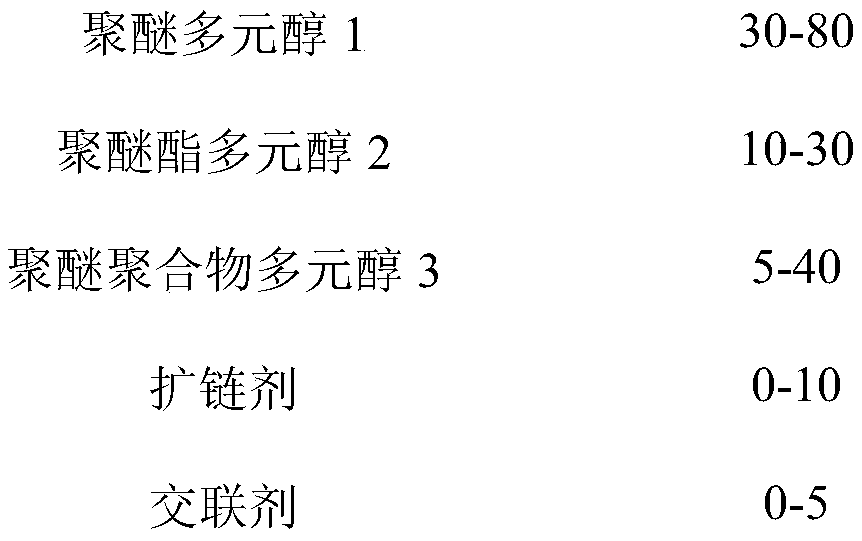

[0037]

[0038]

[0039] A component material: polyether polyol 1 adopts 330NG (Shandong Bluestar Dongda Chemical Co., Ltd.), polyether ester polyol 2 is self-made, polyether polymer polyol 3 adopts POP36 / 28 (Shandong Bluestar Dongda Chemical Industry Co., Ltd.) limited liability company), the chain extender adopts ethylene glycol, the crosslinking agent adopts triethanolamine, the foam stabilizer adopts DC2525 (U.S. Air Products Company), the catalyst adopts triethylenediamine, and the blowing agent adopts water. Mix the raw materials in the formula according to the proportion, stir for 1 hour, take a sample for inspection and then get A component.

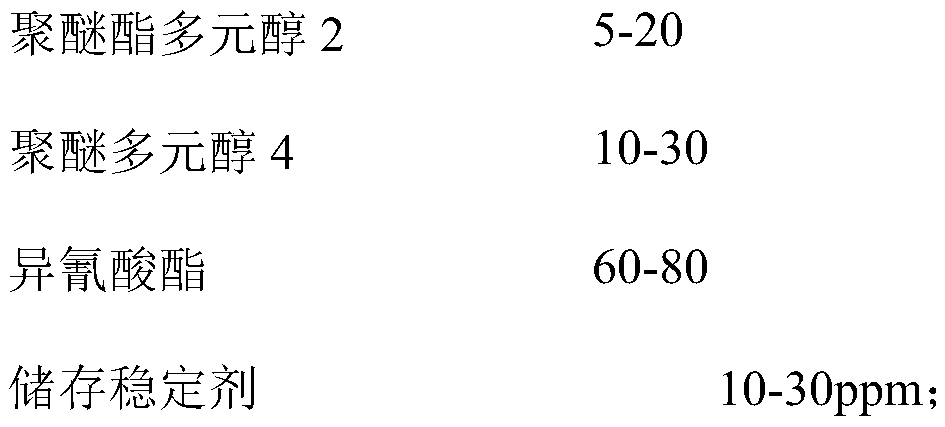

[0040] B component material: self-made polyether polyol 2, polyether polyol 4 uses ED-28 (Shandong Bluestar Dongda Chemical Co., Ltd.), isocyanate is a mixture of pure MDI and liquefied MDI, the ratio is pure MDI: liquefied MDI=50:20.

[0041] The preparation method of described polyether ester polyol 2 is as follows:

[...

Embodiment 2

[0045]

[0046]

[0047] A component material: Polyether polyol 1 adopts 76EK (Shandong Bluestar Dongda Chemical Co., Ltd.), polyether ester polyol 2 is self-made, and polyether polymer polyol 3 adopts HPOP40 (Shandong Bluestar Dongda Chemical Co., Ltd. company), the chain extender uses 1,4-butanediol, the crosslinking agent uses diethanolamine, the foam stabilizer uses DC193 (Air Products Corporation of the United States), the catalyst uses triethylenediamine, and the blowing agent uses water. Mix the raw materials in the formula according to the proportion, stir for 1-2 hours, take a sample for inspection and then get A component.

[0048] Material of component B: self-made polyether ester polyol 2, ED-28 (Shandong Bluestar Dongda Chemical Co., Ltd.) for polyether polyol 4, a mixture of pure MDI, liquefied MDI, and polymerized MDI for isocyanate, and the ratio is pure MDI: liquefied MDI: polymerized MDI=45:10:10.

[0049] The preparation method of described polyether ...

Embodiment 3

[0053]

[0054]

[0055] A component material: Polyether polyol 1 adopts EP-3600 (Shandong Bluestar Dongda Chemical Co., Ltd.), polyether ester polyol 2 is self-made, and polyether polymer polyol 3 adopts POP36 / 28 (Shandong Bluestar Dongda Chemical Co., Ltd.) Great Chemical Co., Ltd.), the chain extender adopts diethylene glycol, the crosslinking agent adopts glycerin, the foam stabilizer adopts DC2525 (Air Products Company of the United States), the catalyst adopts triethylenediamine, and the blowing agent adopts water. Mix the raw materials in the formula according to the proportion, stir for 1-2 hours, take a sample for inspection and then get A component.

[0056]Component B material: Polyether polyol 2 is self-made, polyether polyol 4 is ED-28 (Shandong Bluestar Dongda Chemical Co., Ltd.), isocyanate is a mixture of pure MDI and liquefied MDI, and the ratio is pure MDI: liquefied MDI=20:50.

[0057] The preparation method of described polyether ester polyol 2 is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com