Preparation method and application of C3N4 modified organic membrane

A C3N4, organic membrane technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of application limitations, easy detachment of the bonding layer, pollution, etc., and increase the reuse rate , Easy to recycle and reuse, solve the effect of difficult separation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

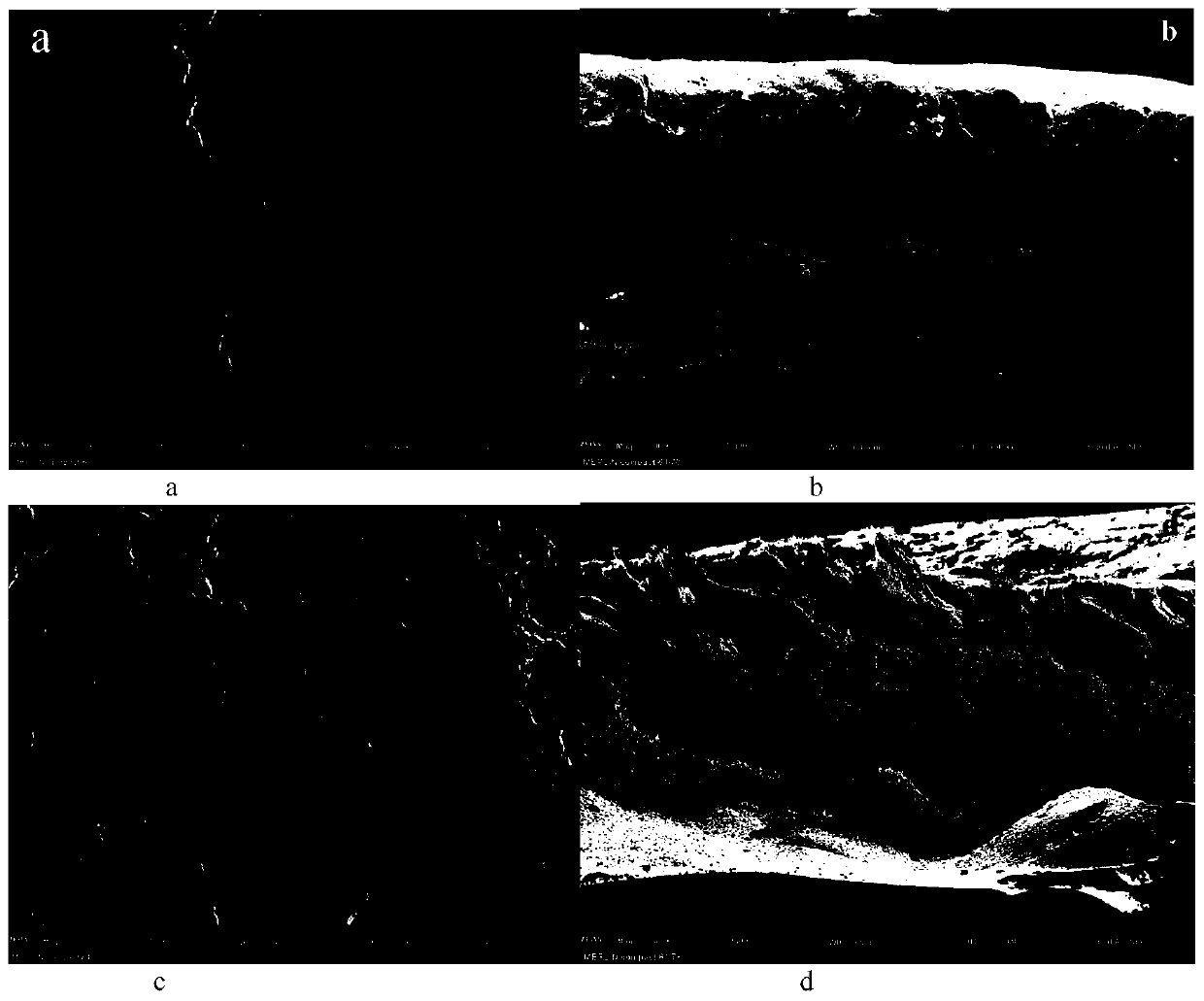

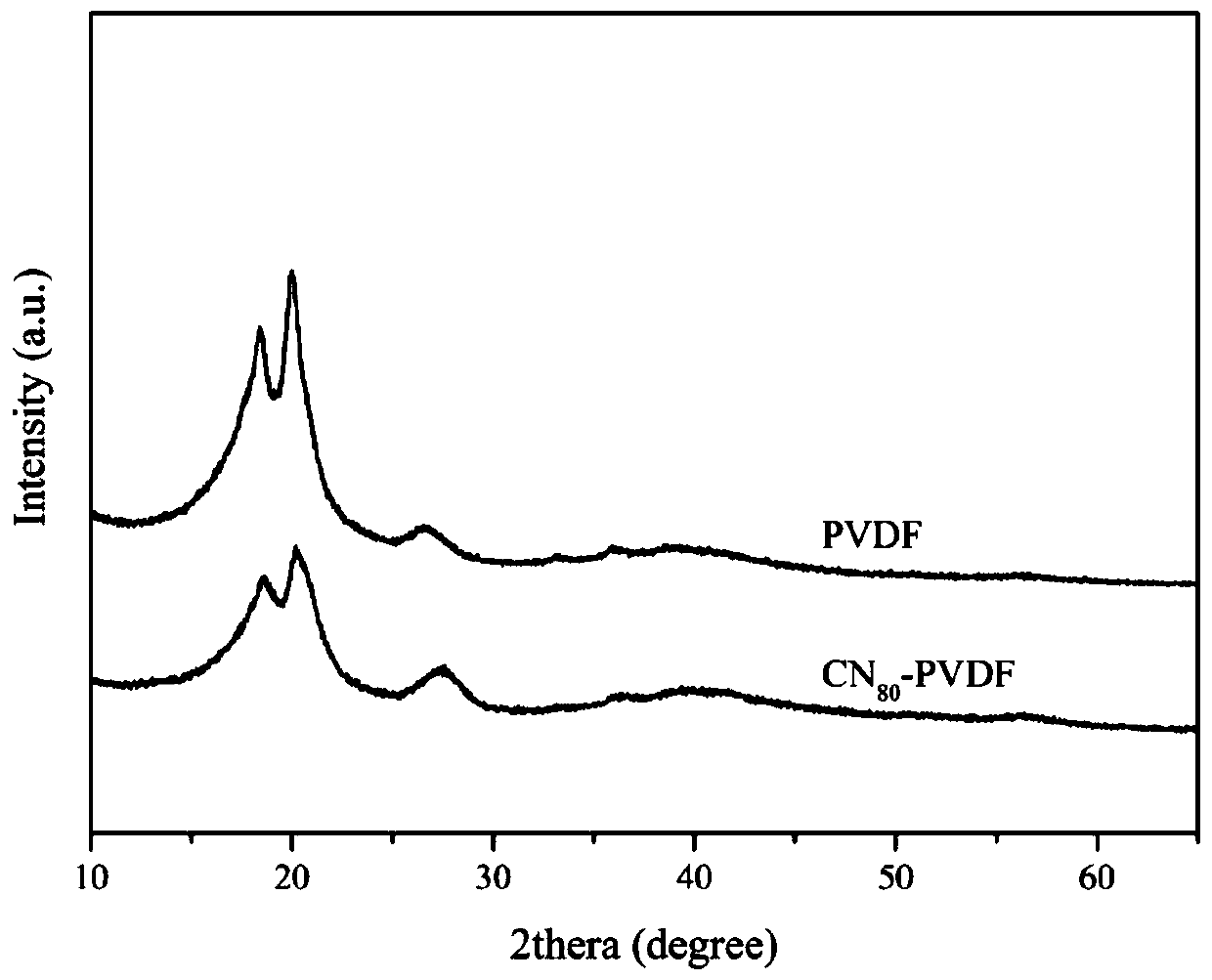

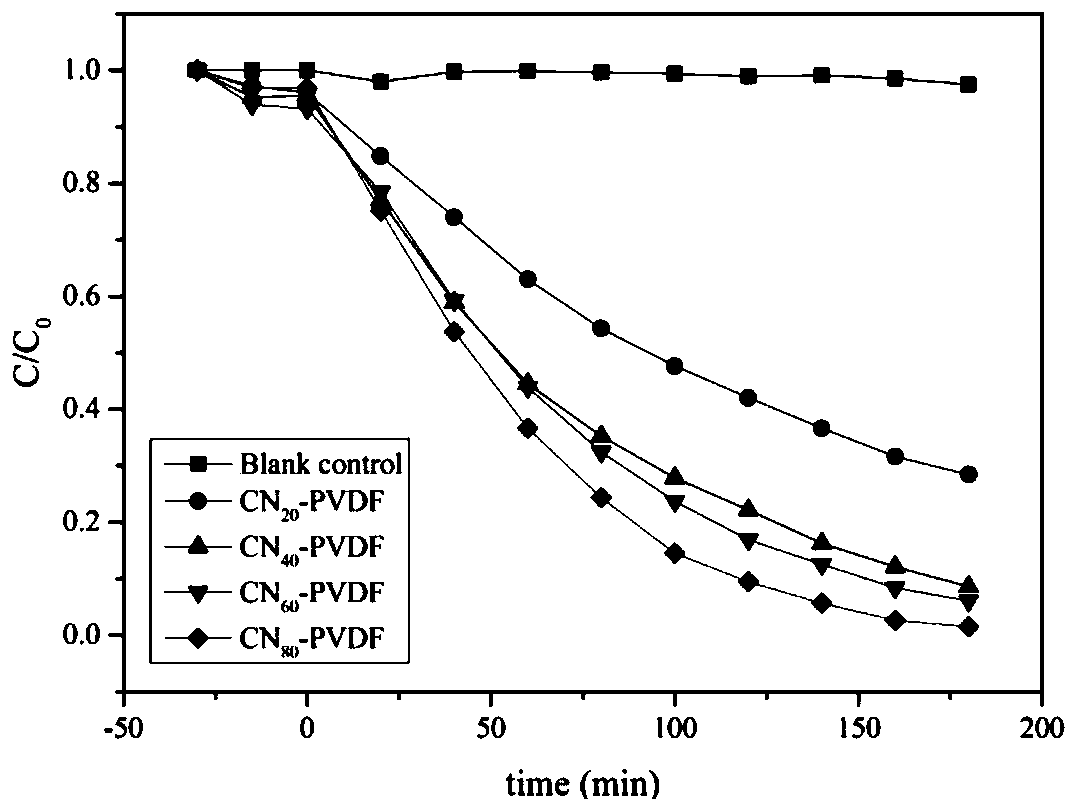

[0033] This embodiment provides a C 3 N 4 A method for preparing a modified organic membrane, in particular to a method for preparing a CN-PVDF (mesoporous graphite phase carbon nitride-polyvinylidene fluoride) hybrid membrane, comprising:

[0034] Step 1) 80 mg carbonized nitrogen CN (mesoporous g-C 3 N 4 ) and 35.7mg of polyvinylpyrrolidone PVP were added to 3ml of 1-methyl-2-pyrrolidone NMP, and ultrasonic 1h was obtained in a 500W ultrasonic cleaner to obtain a mixed solution, and then 500mg of PVDF was added to the mixed solution (that is, the polymeric membrane material PFM ), wherein the mass ratio of CN to PFM is 1:6.25, stirred at 50° C. for 12 hours, left standing for defoaming for 12 hours, to form a casting solution;

[0035]Step 2) Pour the prepared casting solution onto one side of a clean and dry glass plate, scrape a 250 μm thick liquid film with a square applicator, and place the scraped glass plate in the air for 15 seconds Quickly immerse the glass plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com