Automatic brake oil supply device of mechanical shock table brake system

A braking system and impact table technology, applied in the field of braking systems, can solve the problems of inability to work continuously for a long time, low efficiency, and over-testing, etc., to avoid the failure of the braking system, simplify the supply process, and solve the effects of inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

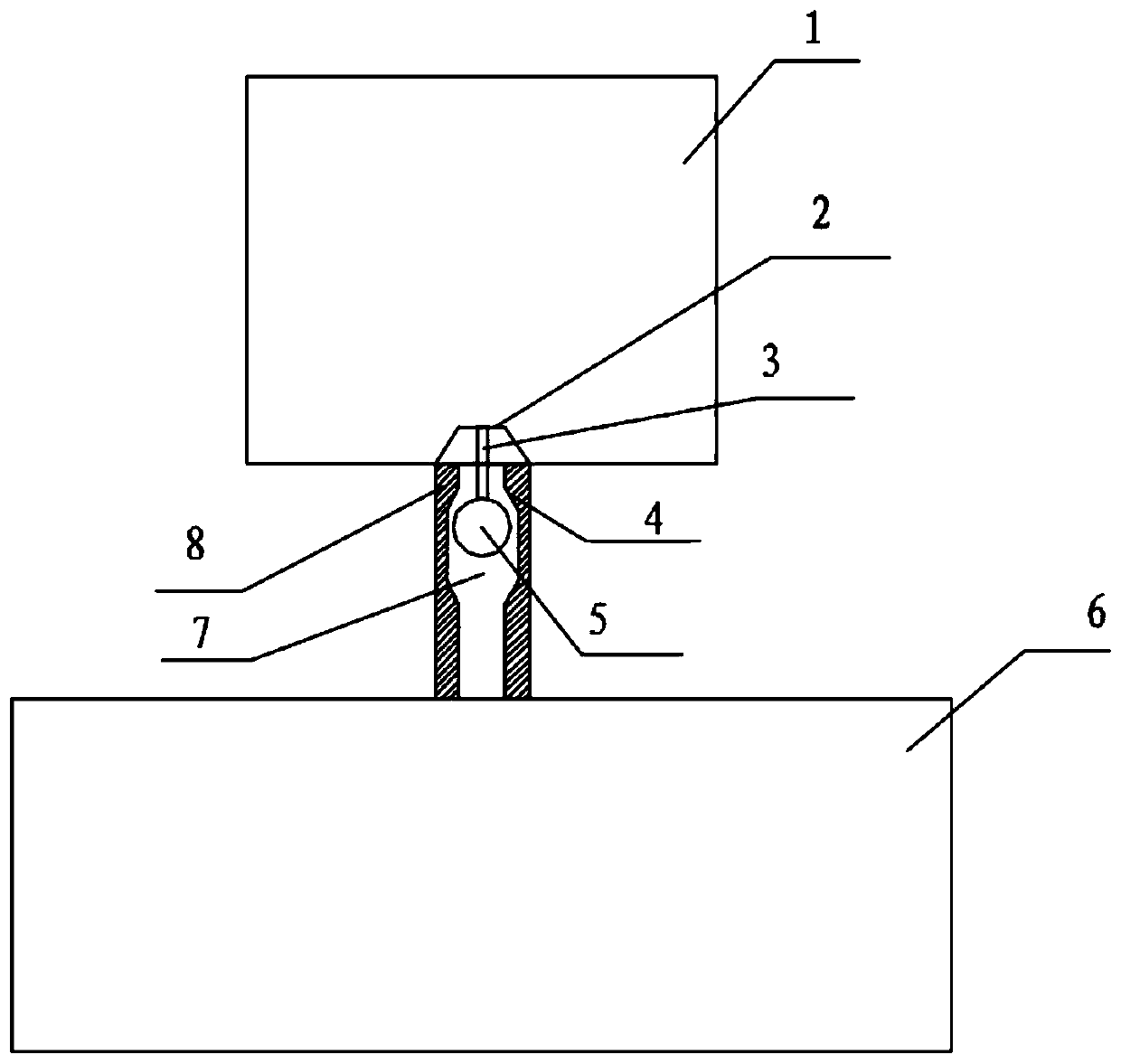

[0021] The present invention is an automatic brake oil replenishment device for the brake system of a mechanical impact table, which includes a fuel supply tank 1, a pressure spring mounting seat 2, a pressure spring 3, a sealing cone surface 4 of an oil supply pipe, a sealing ball 5, an impact table brake oil passage 6, and a pressure spring 3. oil passage 7 and oil supply pipe 8, the oil supply tank 1 is arranged above the impact platform brake oil passage 6, the top of the oil supply tank 1 is provided with a fuel filler 101, and the fuel filler 101 is provided with a sealing cover 102, the The oil supply tank 1 is connected to the brake oil passage 6 of the impact table through the oil supply pipe 8, and the oil supply pipe 8 is provided with an oil supply passage 7, and the oil supply passage 7 connects the oil supply tank 1 with the brake oil passage 6 of the impact table , the upper and lower sides of the oil replenishment channel 7 are respectively provided with symmetr...

Embodiment 2

[0028] This embodiment is based on Embodiment 1, and the similarities with Embodiment 1 will not be repeated, only the differences are described: the upper part of the pressure spring mounting seat 2 is a circular truncated structure, and the bottom of the circular truncated structure is provided with a pillar 202 .

[0029] Further, the number of the pillars 202 is N, where N≧3, and the N pillars 202 are equally spaced.

[0030] Working principle: Inject an appropriate amount of brake oil 9 into the oil supply tank 1, and the brake oil 9 flows into a part of the oil supply channel 7 through the oil outlet 104 and the oil drain groove 201 or the pillar 202 on the pressure spring mounting seat 2, and mechanically impacts the brake When the system is not running, the sealing ball 5 is in contact with the oil supply pipe sealing cone 4 in the oil supply pipe 8 under the pressure of the brake fluid of the brake system, and plays the role of sealing the oil supply passage to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com