Control system for urea pump

A control system and urea pump technology, applied in the direction of electronic control, exhaust treatment, mechanical equipment, etc. of exhaust gas treatment devices, can solve the problems of high system cost and large installation space, and achieve cost reduction, simplified layout, accurate The effect of closed loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

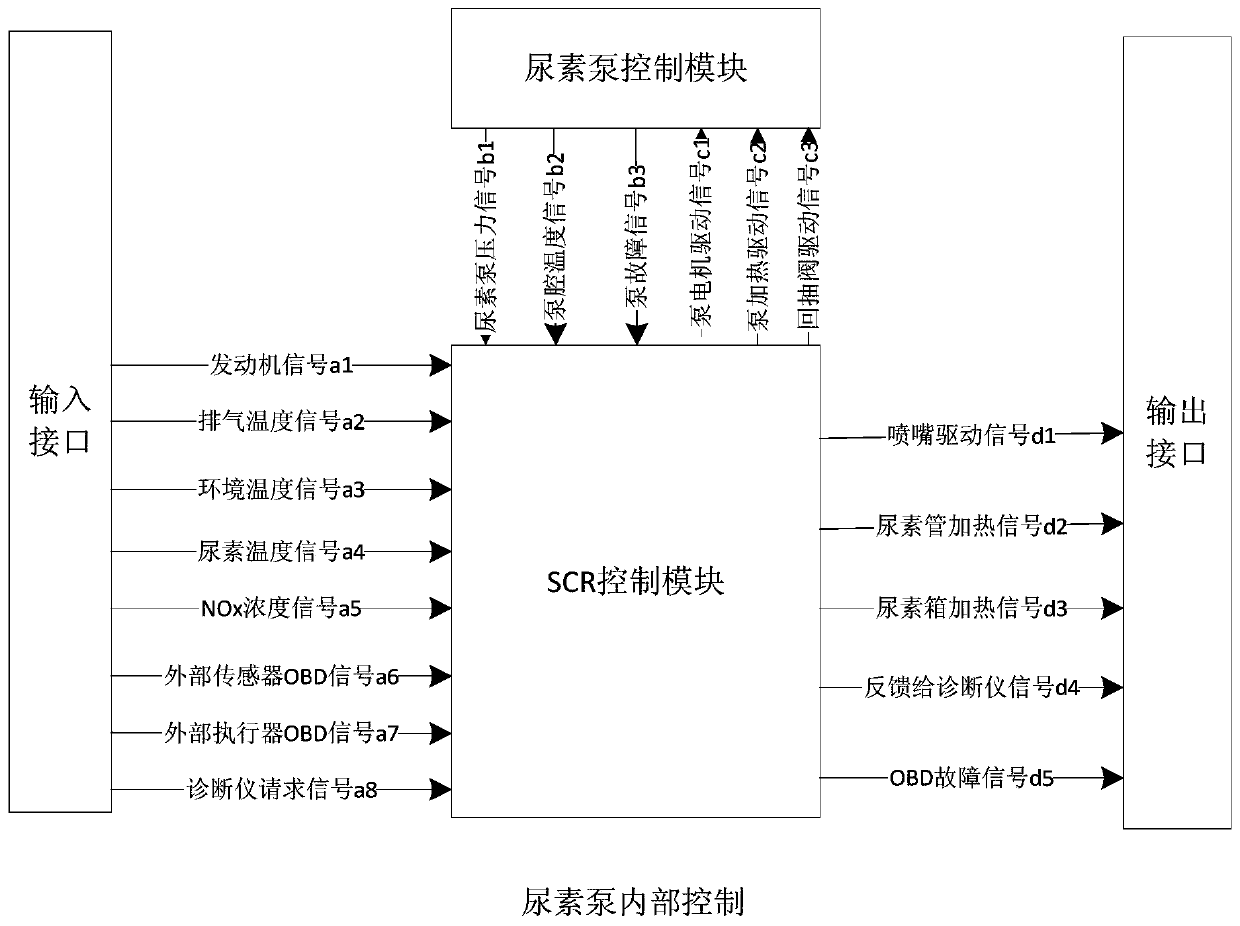

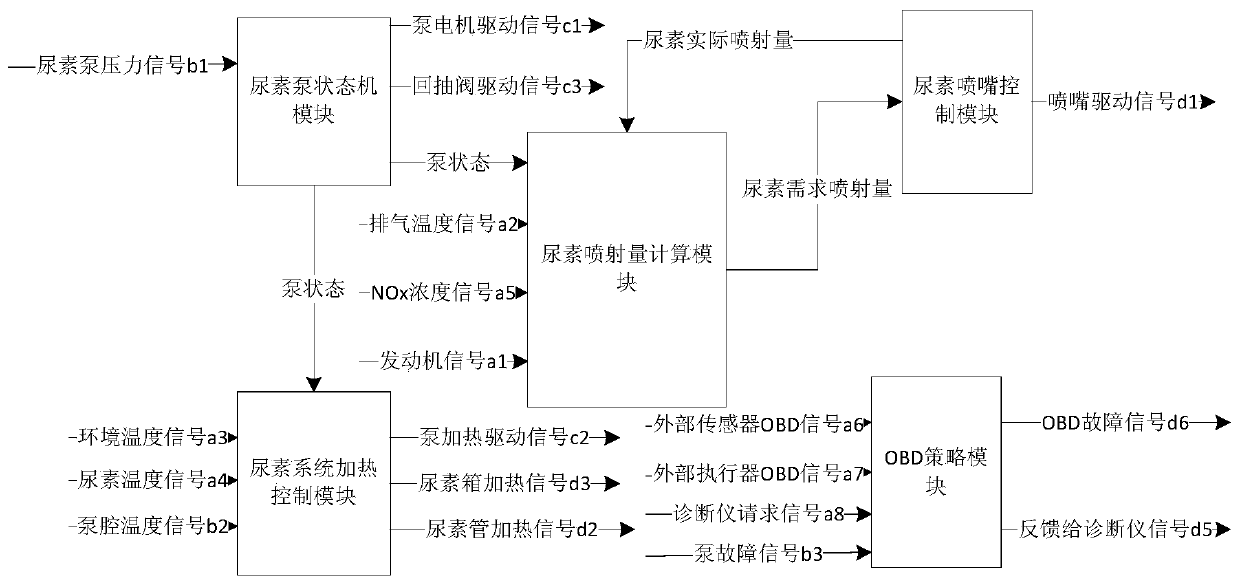

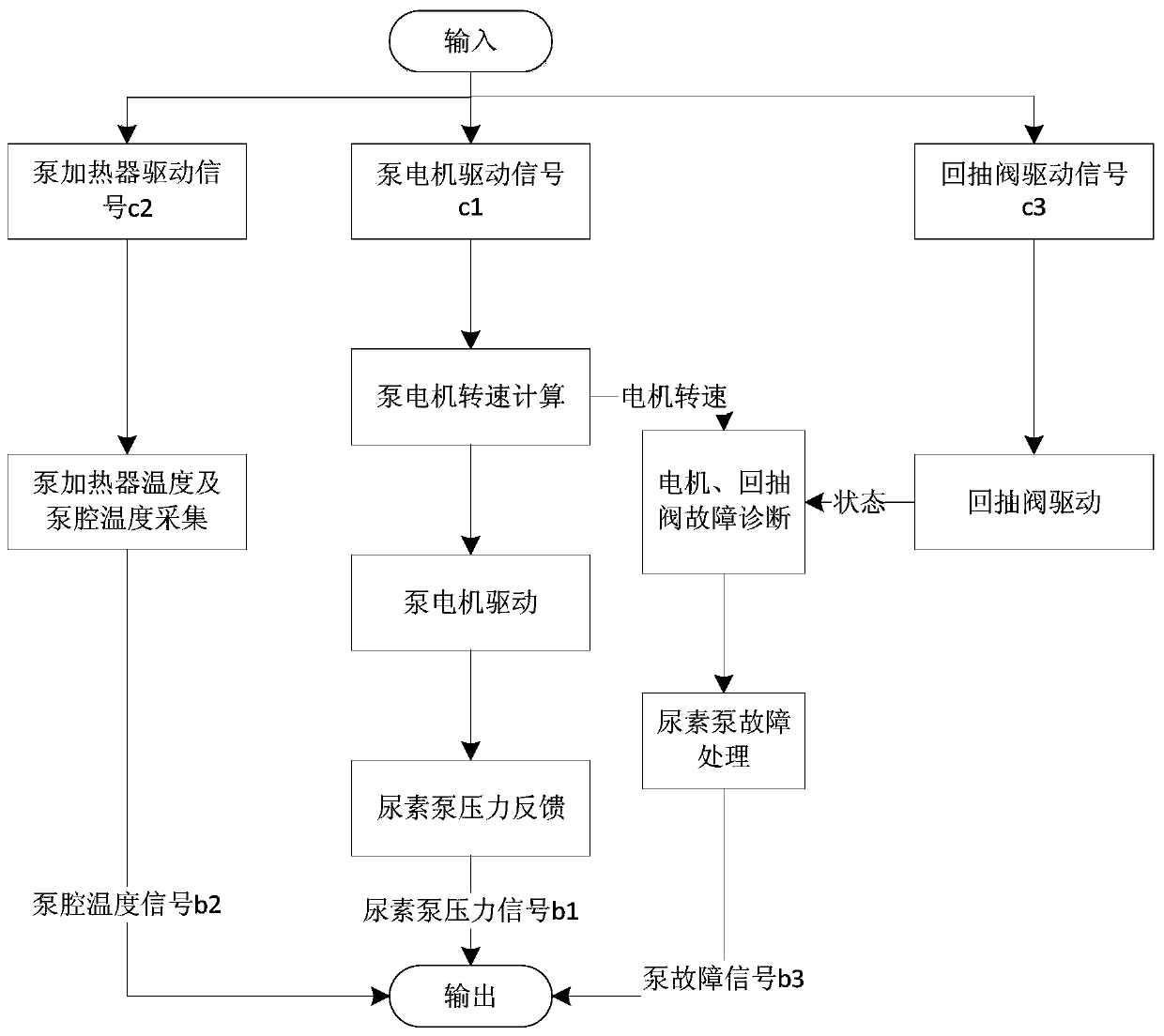

[0027] The control system for the urea pump proposed by the embodiment of the present invention can realize all control of the SCR post-treatment system, including urea pump pressure control, urea injection volume control, urea heating control and OBD diagnosis control of the SCR system;

[0028] The control system for the urea pump includes an input interface module, an output interface module, an SCR control module and a urea pump control module;

[0029] The input interface module is used to transmit external input signals to the SCR control module. The external input signals include: engine signal a1, exhaust temperature signal a2, ambient temperature signal a3, urea temperature signal a4, NOx concentration signal a5, external sensor OBD signal a6 , external actuator OBD signal a7, diagnostic instrument request signal a8;

[0030] The output interface modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com