Detoxification device and detoxification method of carbonylated alloy

The technology of carbonylation alloy and furnace carbonylation alloy is applied in the field of a carbonylation alloy detoxification device, which can solve the problems of carbonylation alloy adsorption and the like, and achieve the effects of being beneficial to recovery, having good detoxification effect and improving detoxification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

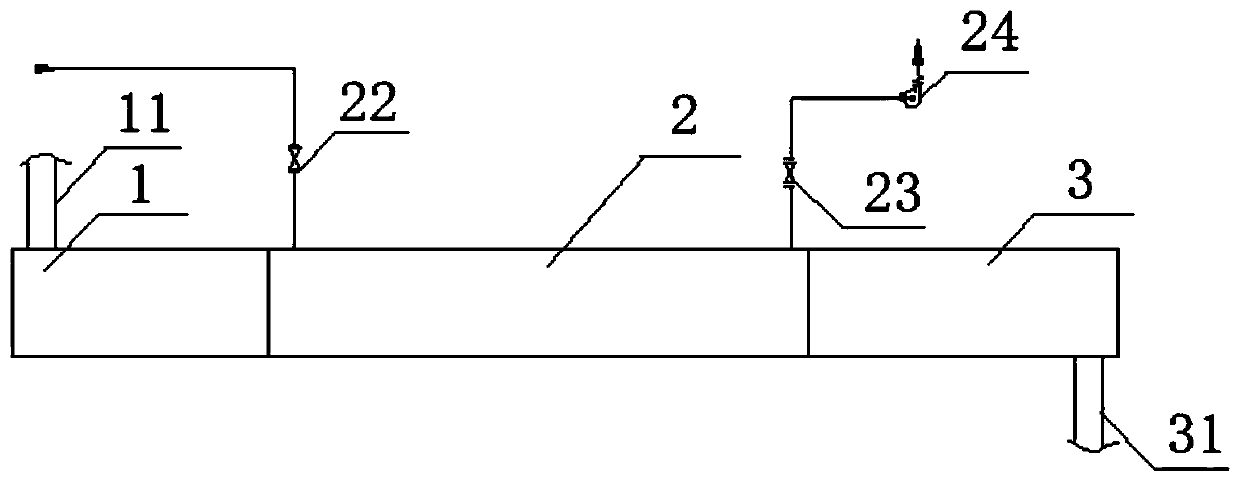

[0018] like figure 1 As shown, a carbonyl alloy detoxification device includes a steel belt detoxification furnace and a steel belt detoxification furnace motor, and the steel belt detoxification furnace motor is used to drive the steel belt detoxification furnace to work; the steel belt detoxification furnace is equipped with two gas curtains, two The air curtain divides the steel strip detoxification furnace into detoxification furnace distributing area 1, detoxification furnace carbonylation detoxification area 2 and detoxification furnace cooling area 3; The argon gas inlet, the argon gas inlet of the detoxification furnace is connected to one end of the argon gas pipeline provided with the inlet valve 22, and the other end of the argon gas pipeline is connected to a container filled with argon gas, and the detoxification furnace carbonyl detoxification zone 2 is close to the detoxification furnace cooling zone One end of 3 is provided with detoxification furnace exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com