High-adhesion water-based electrostatic white finish paint and preparation method thereof

A high-adhesion, white topcoat technology, applied in the field of wood lacquer, can solve the problems of low adhesion of white topcoat and high VOC emission, and achieve the effect of improving construction safety, reducing VOC emission, and enriching the coating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

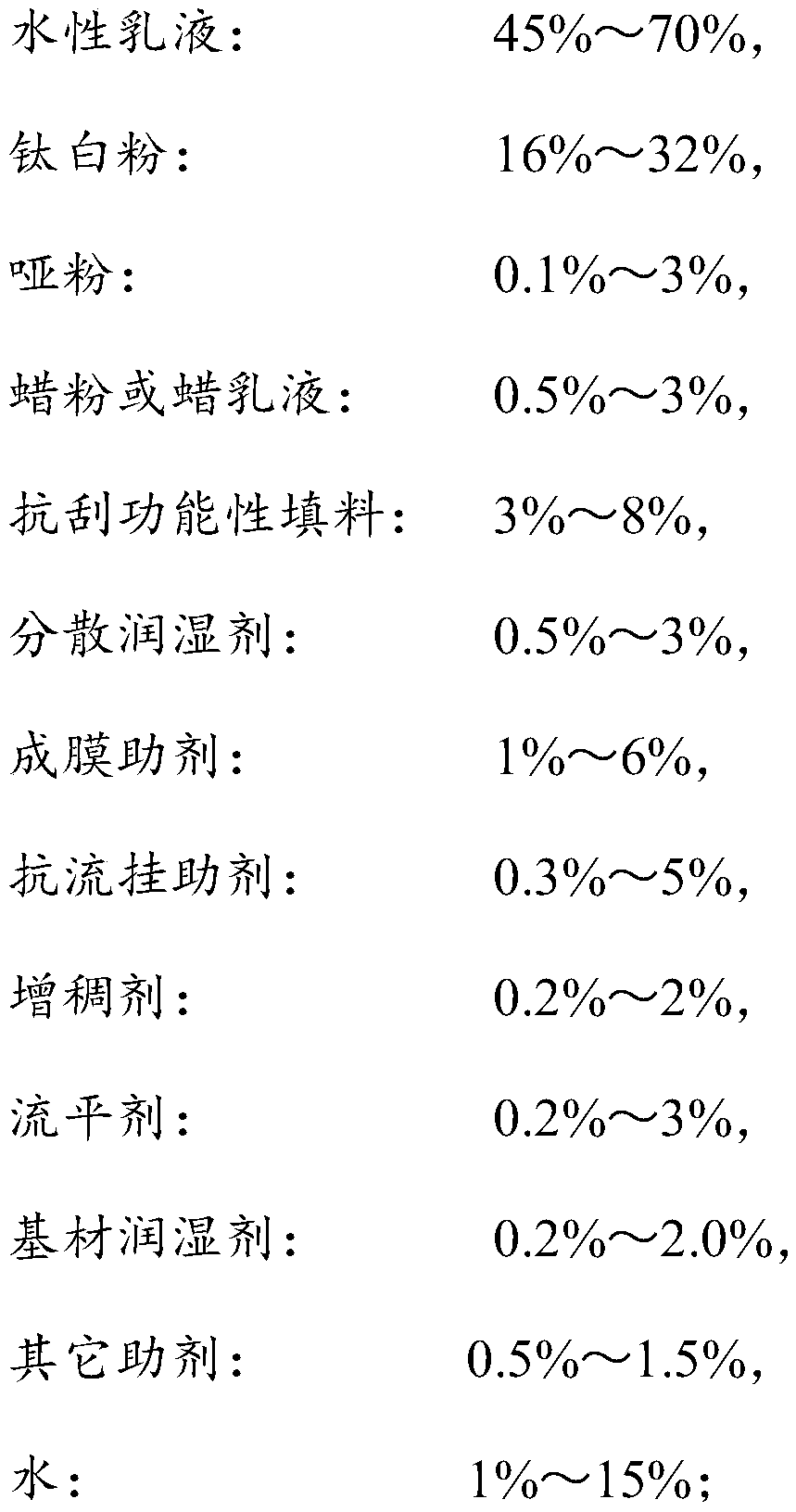

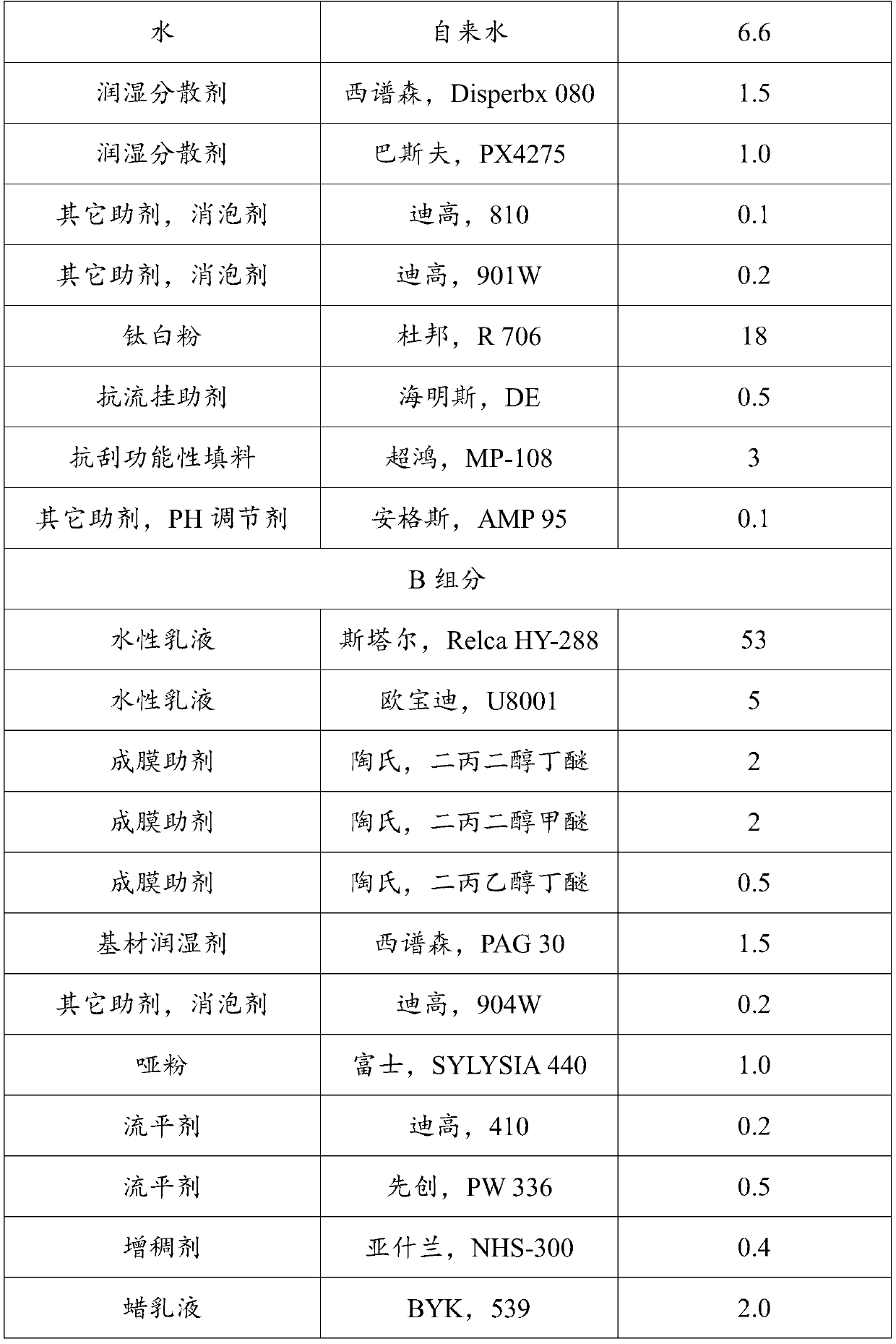

[0031] The component name, quality and performance test of embodiment 1 are shown in the table below.

[0032] Component name, quality and performance test of table 1 embodiment 1

[0033]

[0034]

[0035]

[0036] The preparation process of the water-based three-spectrum white topcoat of the above proportioning ratio is:

[0037] (1) Add component A (water, wetting and dispersing agent, some other additives, titanium dioxide, anti-scratch functional fillers, anti-sag additives) into the container successively under stirring at a rotating speed of 900 rpm, Then disperse for 50 minutes under stirring at a rotating speed of 900 rpm until uniform, the fineness is qualified and there is no oil shrinkage, and the mixture A is obtained;

[0038] (2) Add component B (water-based emulsion, film-forming aid, some other additives, thickener, substrate wetting agent, leveling agent, matte powder, wax emulsion), and then disperse for 25 minutes under stirring at a rotating spe...

Embodiment 2

[0041] The component name, quality and performance test of embodiment 2 are shown in the table below.

[0042] Component name, quality and performance test of table 2 embodiment 2

[0043]

[0044]

[0045] The preparation process of the water-based three-spectrum white topcoat of the above proportioning ratio is:

[0046] (1) Add component A (water, wetting and dispersing agent, some other additives, titanium dioxide, wax powder, anti-scratch functional filler) into the container in turn under stirring at a rotating speed of 600 rpm, and then Disperse for 20 minutes under stirring at 1500 rpm until uniform, with qualified fineness and no oil shrinkage, to obtain mixture A;

[0047] (2) Add component B (water-based emulsion, film-forming aids, some other additives, thickener, substrate wetting agent, leveling agent, dull powder), and then disperse for 30 minutes under stirring at a rotating speed of 900 rpm until uniform, the fineness is qualified and there is no oil s...

Embodiment 3

[0052] The component name, quality and performance test of embodiment 3 are shown in the table below.

[0053] Component name, quality and performance test of table 3 embodiment 3

[0054]

[0055]

[0056]

[0057] The preparation process of the water-based three-spectrum white topcoat of the above proportioning ratio is:

[0058] (1) While stirring at a speed of 700 rpm, add component A (water, wetting and dispersing agent, some other additives, titanium dioxide, wax powder, anti-scratch functional filler, anti-sag additive) in sequence In the container, disperse for 35 minutes under stirring at a rotating speed of 1300 rpm until it is uniform, the fineness is qualified and there is no oil shrinkage, and the mixture A is obtained;

[0059] (2) Add component B (aqueous emulsion, film-forming aid, some other additives, thickener, substrate wetting agent, leveling agent, dull powder), and then disperse for 20min under stirring at a rotating speed of 1100 rpm until unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com