Electronic component soldering tin recycling device

A technology of electronic components and soldering tin, which is applied in the field of electronic component soldering tin recovery and utilization devices, can solve problems affecting production efficiency, difficult to remove soldering tin, high energy consumption, etc., reduce heating time and energy consumption, and improve the effect of soldering tin removal , Recycling mutual promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated by the following examples.

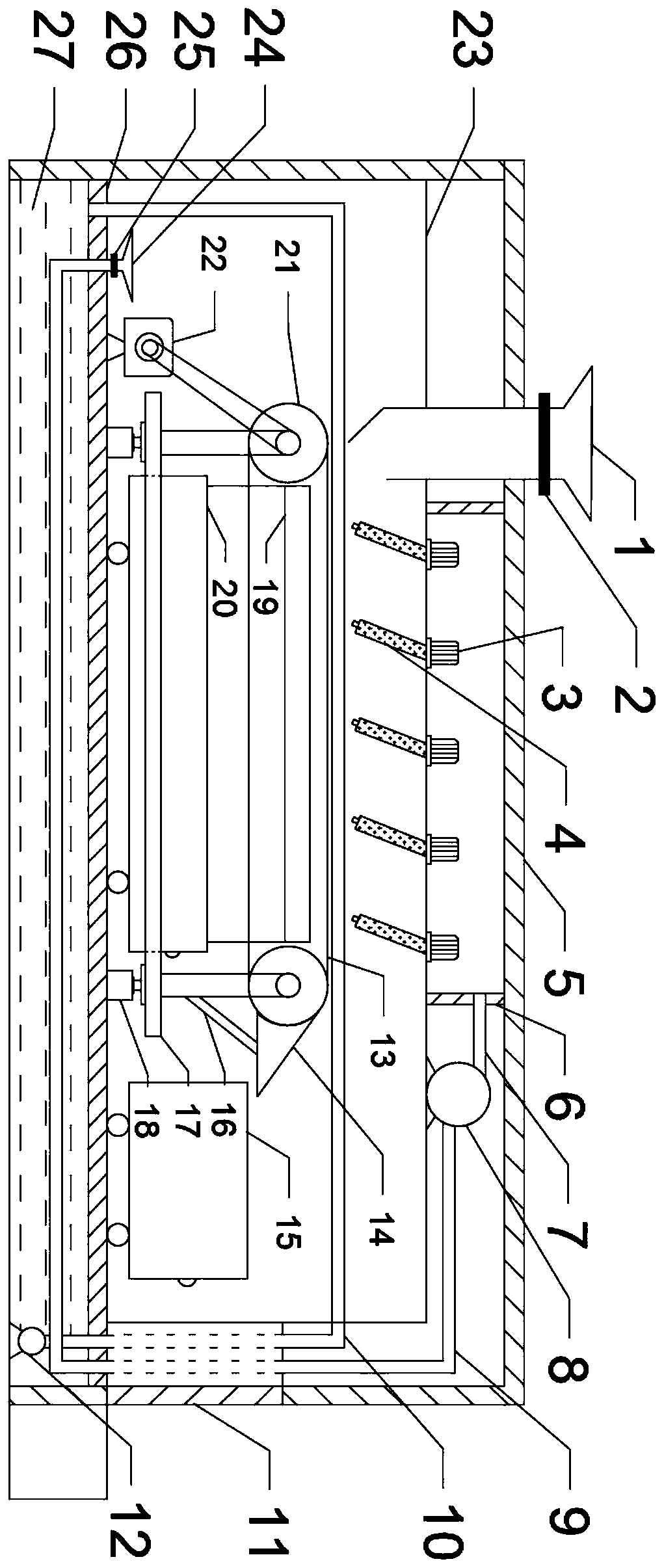

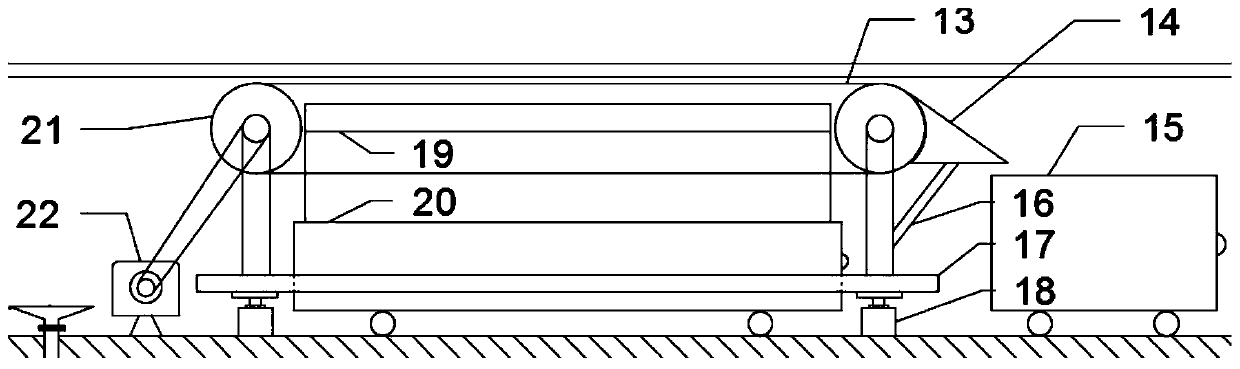

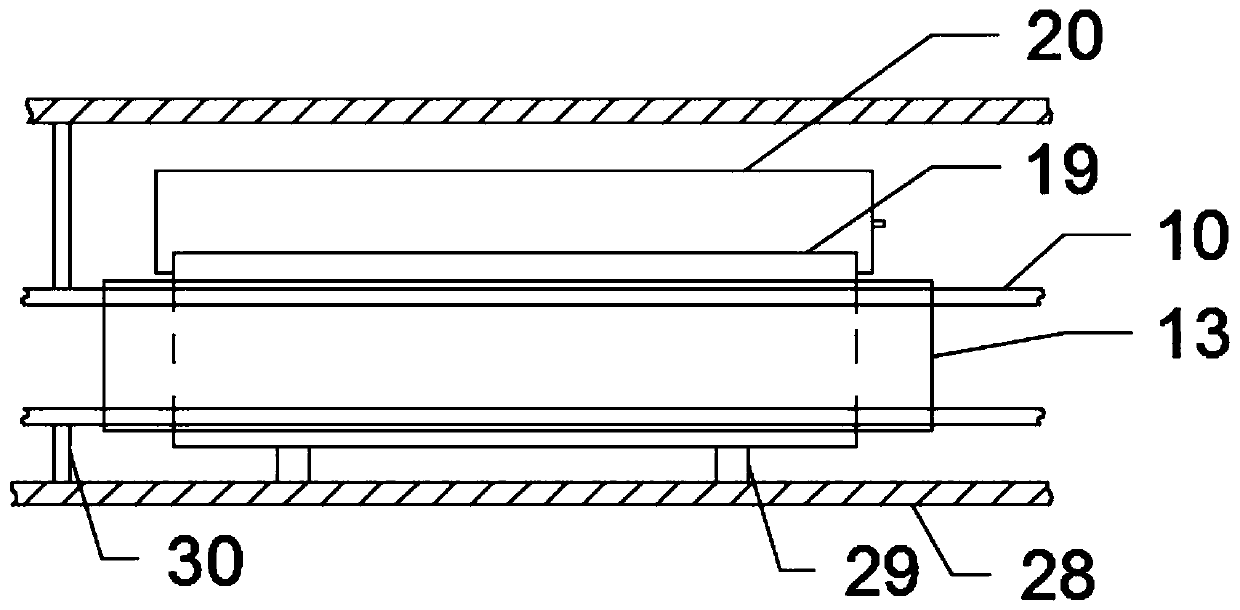

[0025] An electronic component solder recycling device, comprising a case 5, one end of the bottom panel of the case 5 is provided with a feed port 1, the lower end of the feed port 1 is provided with a conveyor belt 13, the conveyor belt 13 is provided on a bottom plate 17, and the bottom plate 17 The bottom is provided with a vibration motor 18, the vibration motor 18 is arranged on the base plate 26, the conveyor belt 13 is driven by the motor 22, the motor 22 is arranged on the base plate 26, and the upper and lower layers of the conveyor belt 13 are provided with a blanking chute 19 in the middle. The material chute 19 lower end is provided with the second collection box 20, and the second collection box 20 is arranged on the base plate 26, and the tail end of conveyer belt 13 is provided with the first collection box 15, and the first collection box 15 is arranged on the base plate 26, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com