Preparation method of graphene modified FeCo absorber

A graphene modification and absorbent technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unsatisfactory low-frequency performance and long time consumption, so as to improve wave-absorbing performance, increase dielectric loss, and improve impedance matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

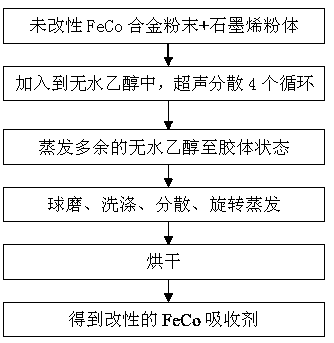

[0032] A kind of preparation method of graphene modified FeCo absorbent, such as figure 1 shown, including the following steps:

[0033] (1) Weigh the FeCo alloy powder with a mass fraction of 99.92%~99.88% and the graphene powder with a mass fraction of 0.08%~0.12% and mix them evenly to obtain a mixture; among them, the particle size of the FeCo alloy powder to be modified The range is 10~50μm. The particle size range of graphene powder is 10~20μm;

[0034] (2) Add the mixture into absolute ethanol, and then carry out ultrasonic dispersion. The duration of dispersion is four dispersion cycles, and one dispersion cycle is 8 minutes;

[0035] (3) Place the dispersed mixture in an evaporator to evaporate to a colloidal state;

[0036] (4) Ball mill the colloidal mixture, the ball milling time is 30min, and the ball-to-material ratio is 10:1; wash the ball-milled mixture, add the washed mixture to absolute ethanol for dispersion, and then place the mixture in Evaporate absol...

Embodiment 1

[0041] Weigh 4.996g (mass fraction 99.92%) of FeCo alloy powder and 0.004g (mass fraction 0.08%) of graphene powder, put them into a 250ml beaker, add 150ml of absolute ethanol, and then use ultrasonic dispersion for four cycles , about 30min; evaporate the excess absolute ethanol to a colloidal state, and then ball mill for 30min; wash the ball-milled sample and disperse it in absolute ethanol, then evaporate the absolute ethanol to dryness with a rotary evaporator, and place it in an oven at 70°C After drying for 3 hours, the modified FeCo absorbent was obtained.

Embodiment 2

[0043] Weigh 4.995g (mass fraction 99.9%) of FeCo alloy powder and 0.005g (mass fraction 0.1%) of graphene powder, put them into a 250ml beaker, add 150ml of absolute ethanol, and then use an ultrasonic disperser to disperse four Evaporate the excess absolute ethanol to a colloidal state, then ball mill for 30 minutes; wash the ball-milled sample and disperse it in absolute ethanol, then evaporate the absolute ethanol to dryness with a rotary evaporator, and dry it in an oven at 60°C After 4h, the modified FeCo absorbent was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com