Self-adaptive vamp for fitting foot

A self-adaptive, vamp technology, applied in shoe uppers, footwear, applications, etc., can solve the problems of complex processing, degumming, vamp bending, etc., and achieve the effect of improving stress, reducing wear, and reducing bending deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

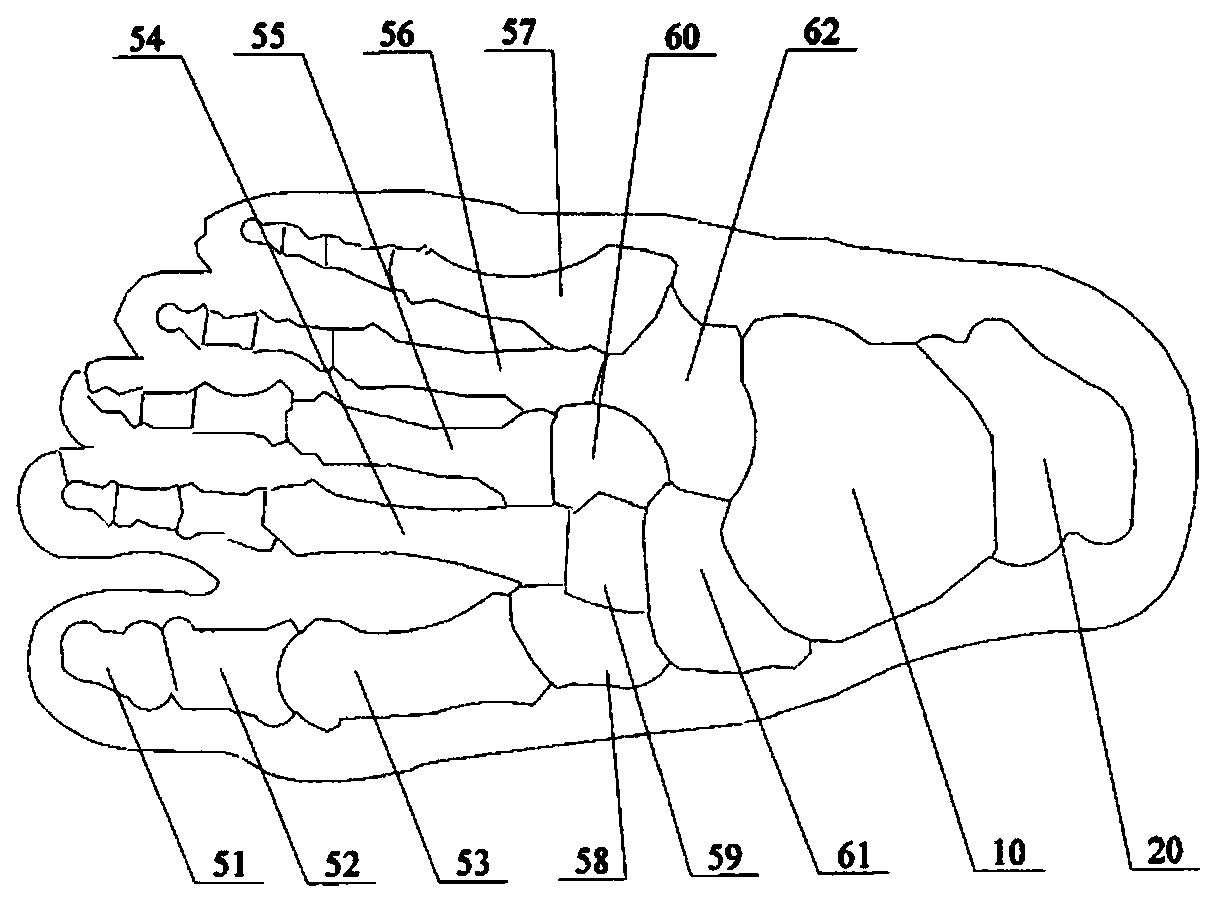

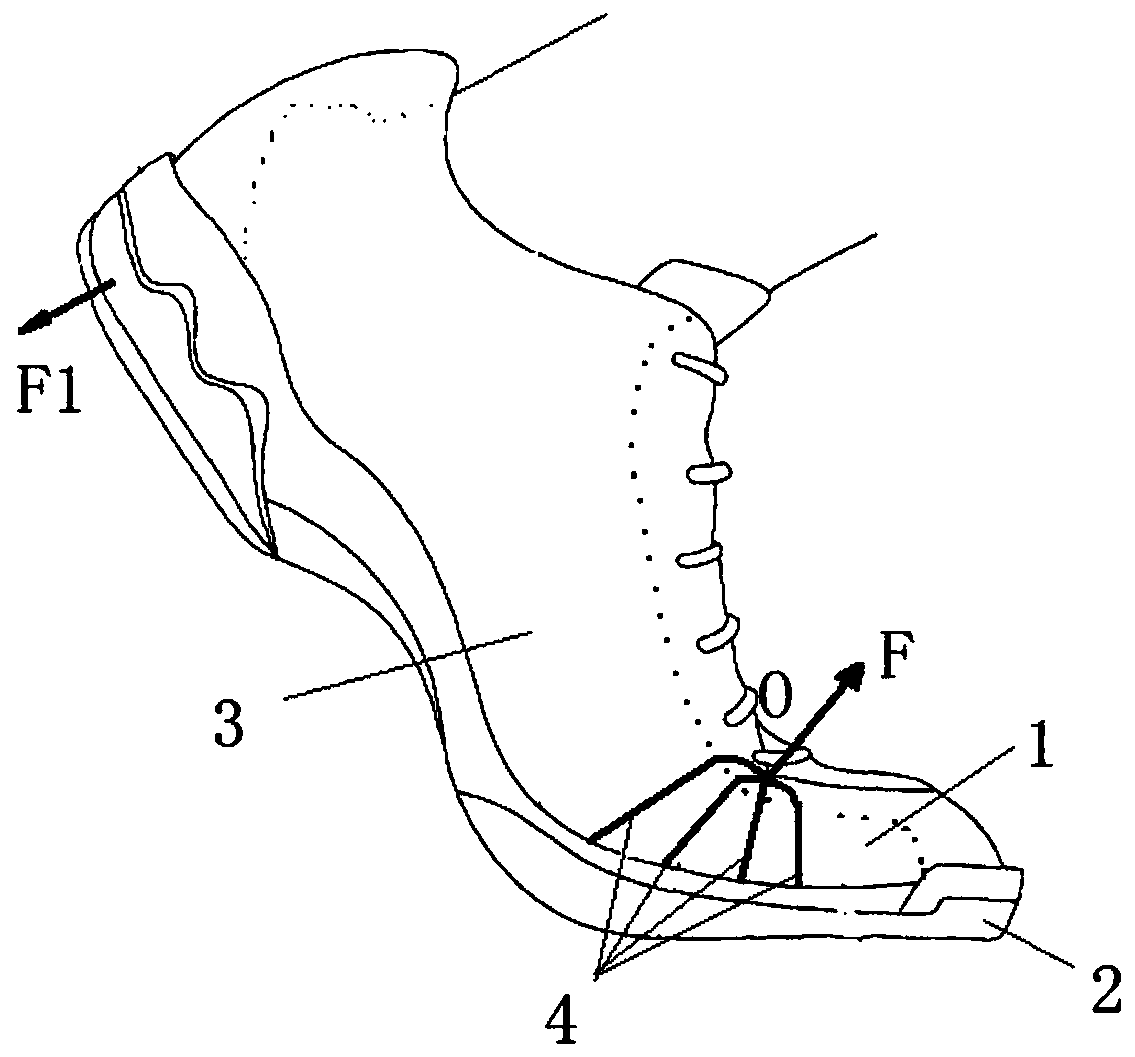

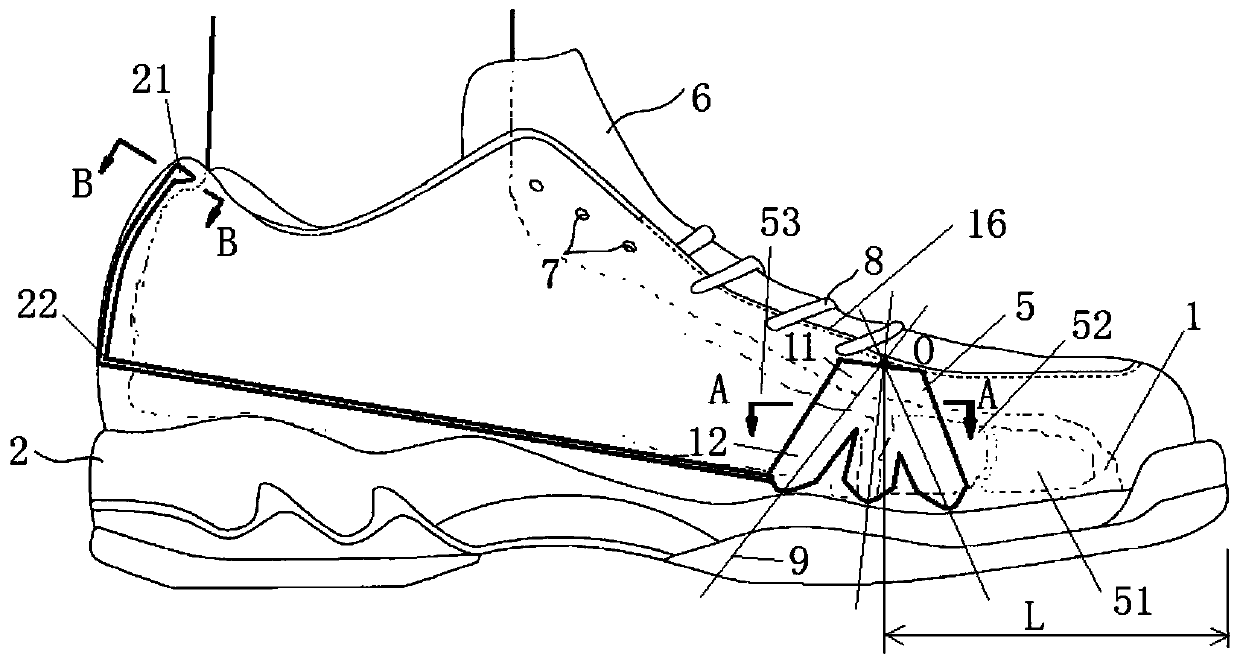

[0038] Such as figure 2 As shown, when people are walking or running, they need the pedaling action of the foot. During the pedaling action of the foot, the vamp will bend, and the foot will bend at the metatarsophalangeal joint formed by the proximal phalanx and metatarsal bone, which will then drive the vamp to flex. Squeeze deformation, in which, the instep will generate a pressing force F on the upper, and at the same time, the upper will be subjected to the extrusion force generated by the deformation of the upper, so that the force on the upper boundary of the upper and the instep will be exerted. Complex, the deformation of the upper has no specific rules, and the bending crease here is an irregular arc structure, such as figure 2 As shown, however, in the area between the instep contact surface and the sole on the side of the vamp, since no feet direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com