Boiling-resistant paint and preparation method thereof, boiling-resistant coating and preparation method thereof, and application of boiling-resistant coating

A water-resistant, coating technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as cracking and insufficient adhesion, and achieve the effects of improving adhesion, crack resistance, and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

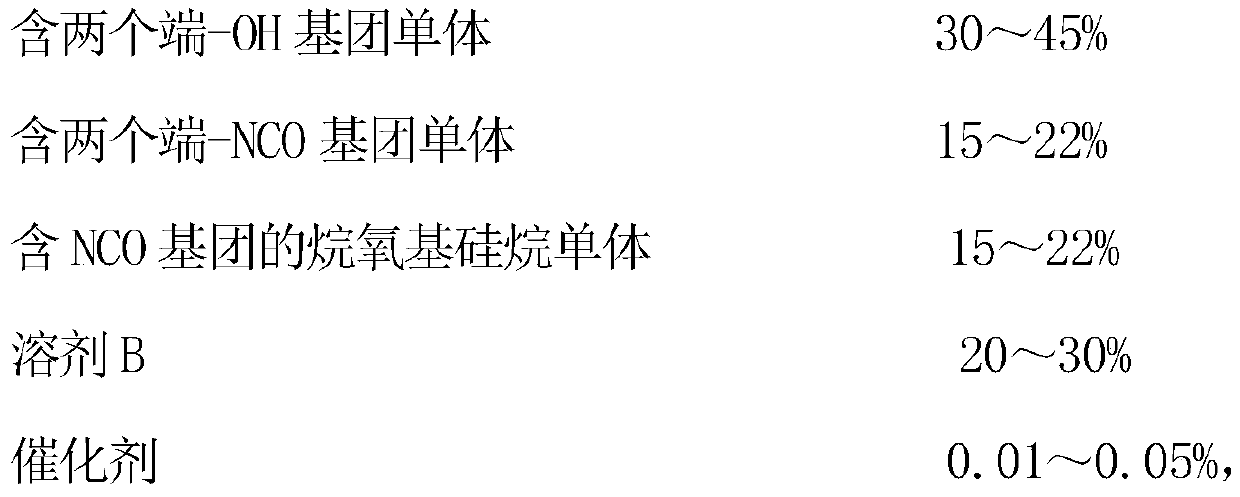

[0024] Preparation of the flexible segment: Add 50g of 1-6 hexanediol and 22g of hexamethylene diisocyanate (HDI) into a three-necked flask, add 0.05g of dibutyltin dilaurate and continue to react at 50°C for 12 hours, then start to add 25g of 3- Isocyanate propyltriethoxysilane was added dropwise in 1-2 hours, and the reaction was continued for 8 hours, and then 33 g of xylene was added and stirred for 0.5 hours to obtain R1.

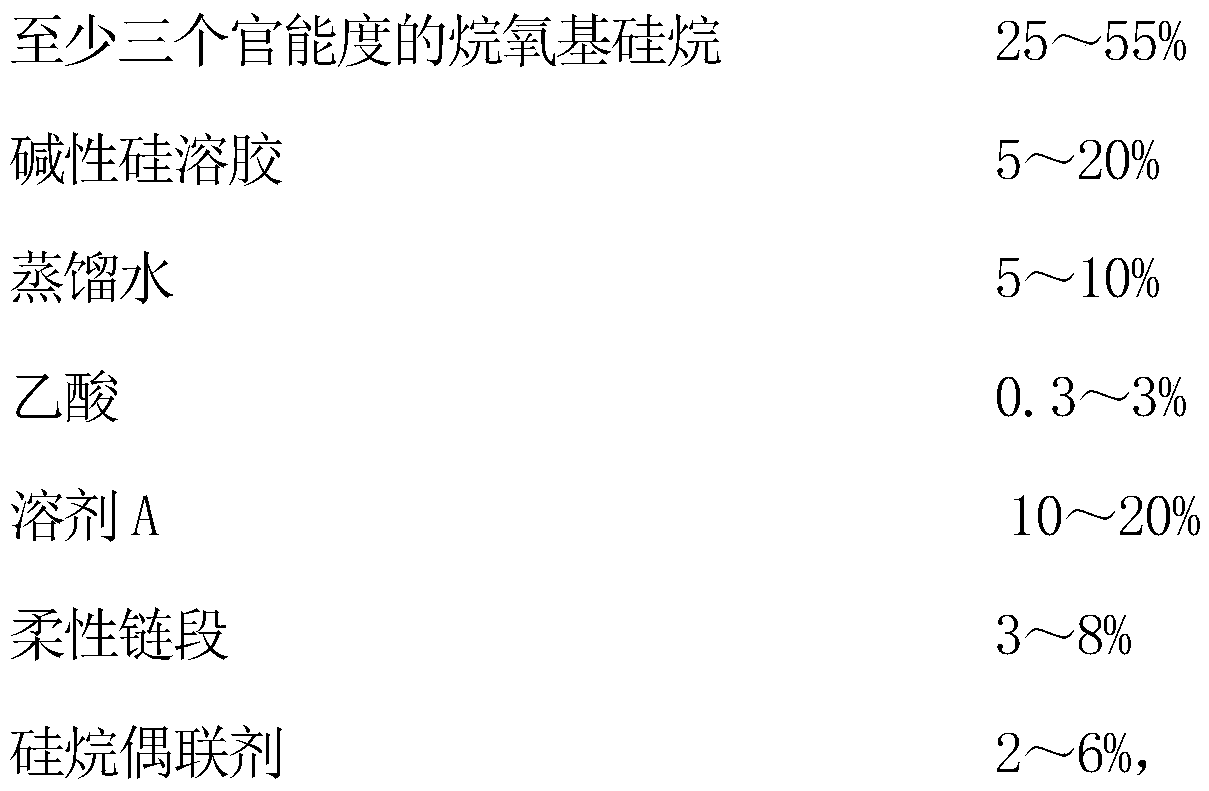

[0025] Preparation of water-resistant coating: Add 25g of alkaline silica sol and 15g of distilled water to the reactor as a primer, add 4g of acetic acid to adjust the pH, add 70g of methyltriethoxysilane, 30g of tetraethoxysilane and 5g of R1, and continuously stir the reaction After 0.5-1 hour, add 45 g of isopropanol and 12 g of γ-glycidyl etheroxypropyl trimethoxysilane and heat to reflux for 1-3 hours to cool down and stop the reaction to obtain boiling-resistant coating A.

Embodiment 2

[0027] The preparation method of the flexible segment is the same as in Example 1 to obtain R1.

[0028] Preparation of water-resistant coating: add 32g alkaline silica sol and 17g distilled water to the reactor as a primer, add 4g acetic acid to adjust the pH, add 70g methyltriethoxysilane, 20g tetraethoxysilane, 15g dodecafluoroheptane Propyl trimethoxysilane and 7g R1, stirring continuously for 0.5-1h, adding 50g diacetone alcohol and 15g gamma-glycidyloxypropyltrimethoxysilane and heating to reflux for 1-3h to cool down and stop the reaction to obtain coating B.

Embodiment 3

[0030] Preparation of the flexible segment: add 66gPPG800 and 27g dicyclohexylmethane diisocyanate (HMDI) into the there-necked flask, add 0.05g dibutyltin dilaurate continuously, keep the reaction at 50-60°C for 12h, then start to keep warm and drop 25g3- Isocyanate propyltriethoxysilane, dropwise addition of 1-2h is completed, continue to keep warm for 8h, then add 35g of (2-butoxyethyl) acetate and stir for 0.5h to obtain R2.

[0031] Preparation of boil-resistant coating: Add 20g of alkaline silica sol and 15g of distilled water to the reactor as a primer, add 4g of acetic acid to adjust the pH, add 80g of methyltriethoxysilane, 40g of tetraethoxysilane and 10g of R2, and continuously stir the reaction After 0.5-1 hour, add 20 g of diacetone alcohol, 20 g of ethanol and 10 g of γ-(methacryloyloxy)propyltriethoxysilane and heat to reflux for 1-3 hours to cool down and stop the reaction to obtain coating C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com