Method for preparing Bi-2212 precursor powder by inclined rotary sintering process

A technology of bi-2212 and tilting rotation, which is applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of reduced oxygen partial pressure of grains, influence of powder quality, and impurities in powder, so as to reduce thickness and avoid Accumulation and cut-off, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment includes the following steps:

[0043] Step 1. Put Bi 2 o 3 , Ca(OH) 2 , SrCO 3 and CuO are prepared into mixed powder according to the atomic ratio of Bi:Sr:Ca:Cu=1.95:1.95:0.9:1.95;

[0044] or Bi 2 o 3 , Ca(OH) 2 , SrCO 3 Mix with CuO according to the atomic ratio of Bi:Sr:Ca:Cu=(1.95~2.2):(1.95~2.2):(0.9~1):(1.95~2.2), and then prepare a nitrate mixed solution, and then use straw salt co-precipitation method to prepare oxalate mixed powder;

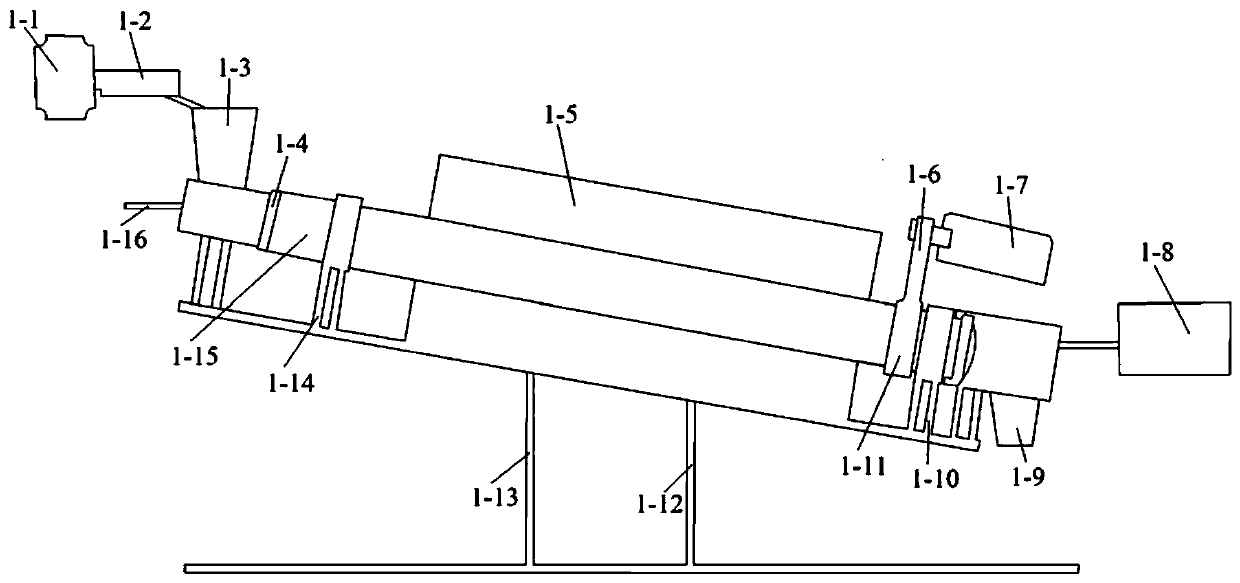

[0045] Step 2. Put the mixed powder obtained in step 1 into the raw material powder storage tank 1-1 of the primary sintering furnace 1 in the inclined continuous rotation automatic sintering equipment as raw material powder, respectively raise the temperature of the primary sintering furnace 1 to 450°C, and sinter at a low temperature. Furnace 2 is heated to 600°C, medium-temperature sintering furnace 3 is heated to 700°C, high-temperature sintering furnace 4 is heated to 800°C, and phase forming sinte...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] Step 1. Put Bi 2 o 3 , Ca(OH) 2 , SrCO 3 Prepare mixed powder with CuO according to the atomic ratio of Bi:Sr:Ca:Cu=2.2:2.2:1:2.2;

[0050] Step 2. Put the mixed powder obtained in step 1 into the raw material powder storage tank 1-1 of the primary sintering furnace 1 in the inclined continuous rotation automatic sintering equipment as raw material powder, respectively raise the temperature of the primary sintering furnace 1 to 500°C, and sinter at a low temperature. Furnace 2 is heated to 650°C, medium-temperature sintering furnace 3 is heated to 750°C, high-temperature sintering furnace 4 is heated to 820°C, and phase-forming sintering furnace 5 is heated to 850°C and kept for 30 minutes. The furnace tubes 1-15 of the sintering furnace 2, the medium-temperature sintering furnace 3, the high-temperature sintering furnace 4, and the phase-forming sintering furnace 5 are inclined along the feeding direction to th...

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1. Put Bi 2 o 3 , Ca(OH) 2, SrCO 3 Mix with CuO according to the atomic ratio of Bi:Sr:Ca:Cu=2:2:0.95:2, then prepare a nitrate mixed solution, and then adopt the oxalate coprecipitation method to prepare an oxalate mixed powder;

[0055] Step 2. Put the oxalate mixed powder obtained in step 1 into the raw material powder storage tank 1-1 of the primary sintering furnace 1 in the inclined continuous rotation automatic sintering equipment as raw material powder, and raise the temperature of the primary sintering furnace 1 to 470°C respectively , Low-temperature sintering furnace 2 is heated to 620°C, medium-temperature sintering furnace 3 is heated to 720°C, high-temperature sintering furnace 4 is heated to 810°C, and phase-forming sintering furnace 5 is heated to 840°C and kept for 30 minutes, and then the primary sintering furnace after heat preservation is sequentially 1. The furnace tubes 1-15 of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com