A kind of nanoporous graphene and its preparation method and application

A graphene and nanopore technology, applied in the direction of graphene, single-layer graphene, nano-carbon, etc., can solve the problems of inability to guarantee the complete pore size, harsh process conditions, complex process conditions, etc., and achieve large horizontal scale and orderly. High performance, high field effect mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Under the protection of argon, 1mg of 1,3,5-benzenetriboronic acid tripinacol ester (CA number: 365564-05-2, FW: 455.996), 1mg of 1,3,5-triiodobenzene (CAS number: 626-44-8, FW:455.801) and 10mg tetrakis(triphenylphosphine)palladium Pd(PPh 3 ) 4 Dissolve in 20mL of toluene to obtain an organic solution, and dissolve 10mg of sodium carbonate in 10mL of water to obtain an aqueous solution of sodium carbonate. The organic solution and the sodium carbonate aqueous solution were placed in the same container to form an interface, and stood still for 30 days at 2°C to obtain nanoporous graphene at the interface.

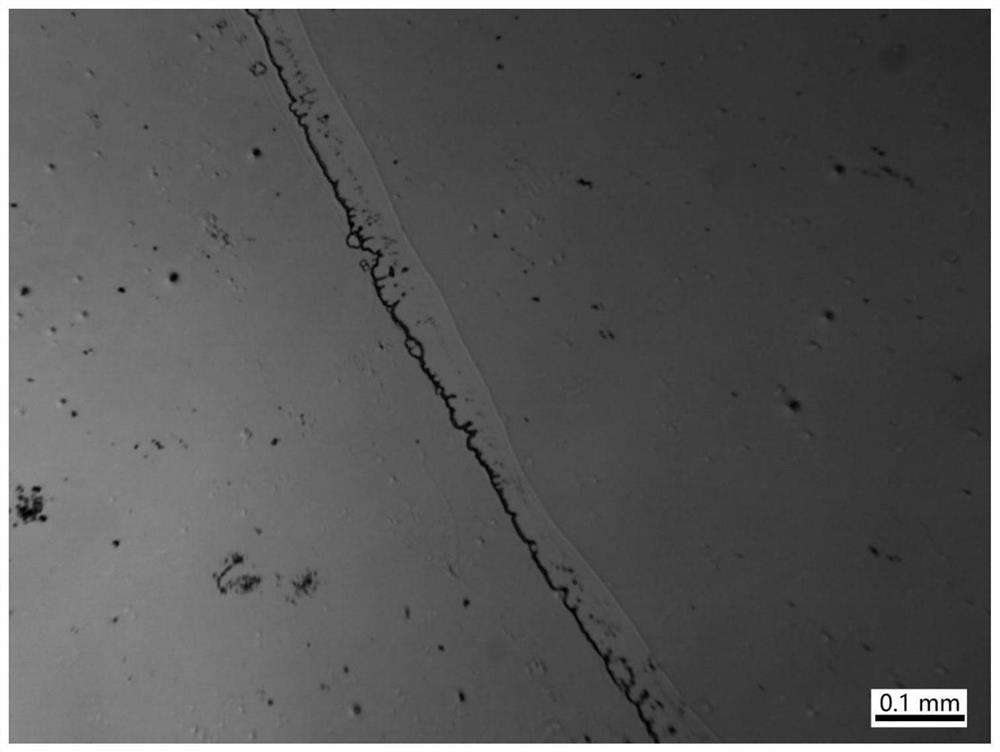

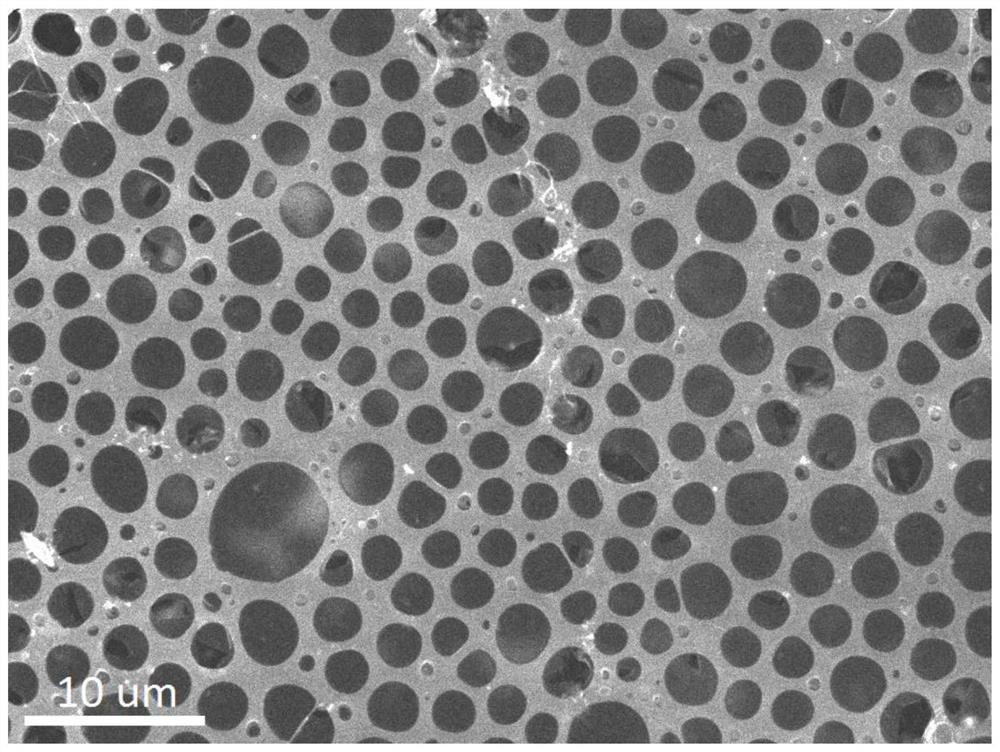

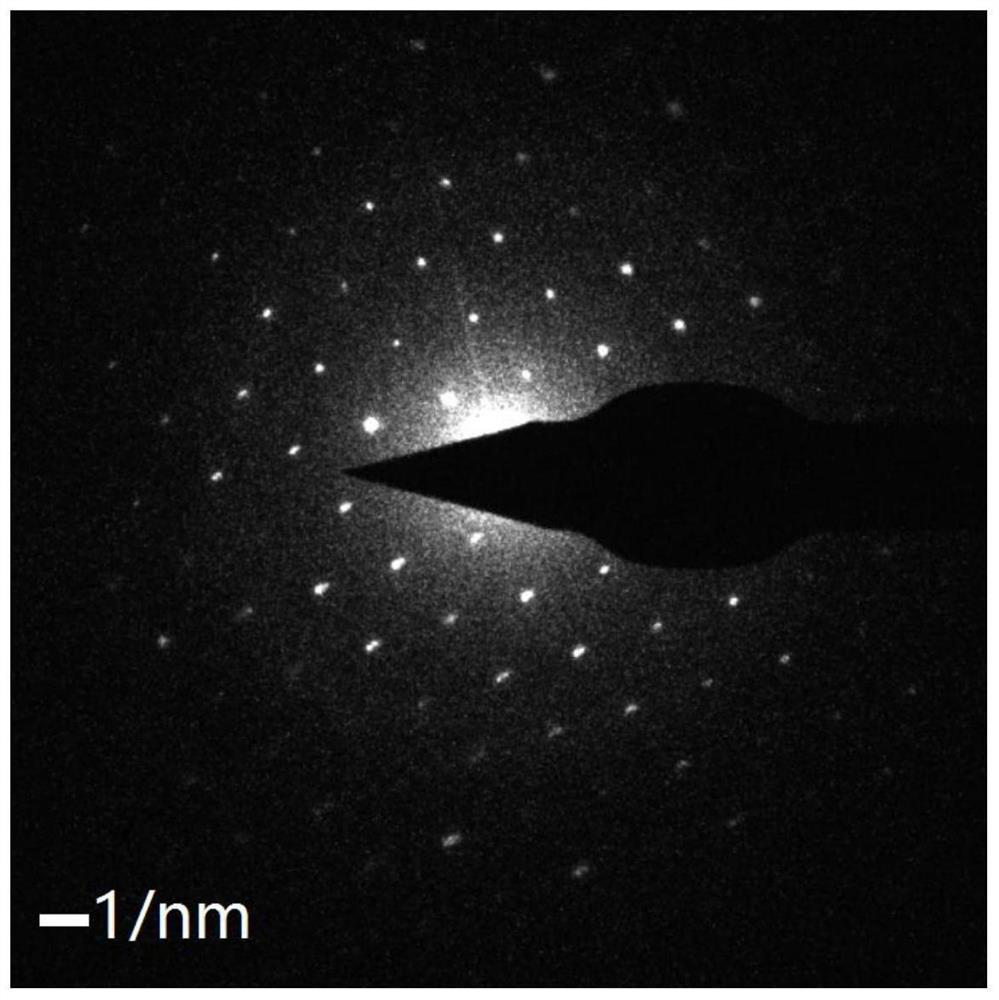

[0039] The nanoporous graphene was fished out from the silicon circle with the prepared gold electrode, washed three times with toluene, dichloromethane, water, and ethanol respectively, dried naturally and then vacuum-dried at room temperature, and the dried nanoporous graphite was The alkene is directly loaded on the glass slide, and observed with an optical micr...

Embodiment 2

[0047] Under the protection of argon, 1mg of 1,3,5-benzenetriboronic acid tripinacol ester (CA number: 365564-05-2, FW: 455.996), 1mg of 1,3,5-triiodobenzene (CAS number: 626-44-8, FW:455.801) and 10mg tetrakis(triphenylphosphine)palladium Pd(PPh 3 ) 4 Dissolve in 20 mL of chloroform to obtain an organic solution, and dissolve 10 mg of sodium carbonate in 10 mL of water to obtain an aqueous solution of sodium carbonate. The organic solution and the sodium carbonate aqueous solution are placed in the same container to form an interface, and left to stand for 30 days at 2°C to obtain nanoporous graphene at the interface.

[0048] The nanoporous graphene was fished out from the silicon circle with the gold electrode prepared, washed three times with toluene, dichloromethane, water, and ethanol respectively, dried naturally and then vacuum-dried at room temperature, and the nanoporous graphene was measured. The field effect mobility is 9.1×10 -3 cm 2 / Vs.

Embodiment 3

[0050] Under the protection of argon, 1mg 1,3,5-benzenetriboronic acid tripinacol ester (CA number: 365564-05-2, FW: 455.996), 1.5mg 1,3,5-tribromobenzene (CAS number : 626-44-8, FW: 455.801) and 10 mg dichlorobis(triphenylphosphine) palladium Pd(PPh3)2Cl 2 Dissolve in 20 mL of toluene to obtain an organic solution, and dissolve 10 mg of sodium hydroxide in 10 mL of water to obtain an aqueous solution of sodium hydroxide. The organic solution and the sodium hydroxide aqueous solution are placed in the same container to form an interface, and left to stand for 30 days at 10°C to obtain nanoporous graphene at the interface.

[0051] The nanoporous graphene was fished out from the silicon circle with the gold electrode prepared, washed three times with toluene, dichloromethane, water, and ethanol respectively, dried naturally and then vacuum-dried at room temperature, and the nanoporous graphene was measured. The field effect mobility is 1.5×10 -2 cm 2 / Vs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com