Amorphous nanocrystalline powder baking device and magnetic powder core production line applying amorphous nanocrystalline powder baking device

A technology of amorphous nanocrystals and baking equipment, which is applied in transportation and packaging, metal processing equipment, etc., can solve the problems of cost increase, uneven coating, and decrease of powder magnetic permeability, so as to improve the efficiency of roller coating and improve the Economic benefits, save the effect of roller coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Then apply the magnetic powder core production line of the above-mentioned amorphous magnetic powder core preparation method, which will include the following equipment:

[0043] A smelting furnace, which is used in step S1 to smelt corresponding alloy raw materials;

[0044] A strip spraying machine, which is applied in step S2, so that the obtained master alloy is sprayed with strips to prepare corresponding amorphous strips;

[0045] A pulverizer, which is used in step S2 to grind the obtained amorphous strip to obtain a flaky amorphous powder;

[0046] Melting equipment, which is used in step S2 to prepare the obtained master alloy into a spherical amorphous powder by means of water atomization or gas atomization;

[0047] A sieving machine to independently sieve and classify the obtained flake-like amorphous powder and spherical amorphous powder;

[0048] Corresponding stirring equipment, which is applied in steps S3 and S4, to mix the graded amorphous powders of...

Embodiment 1

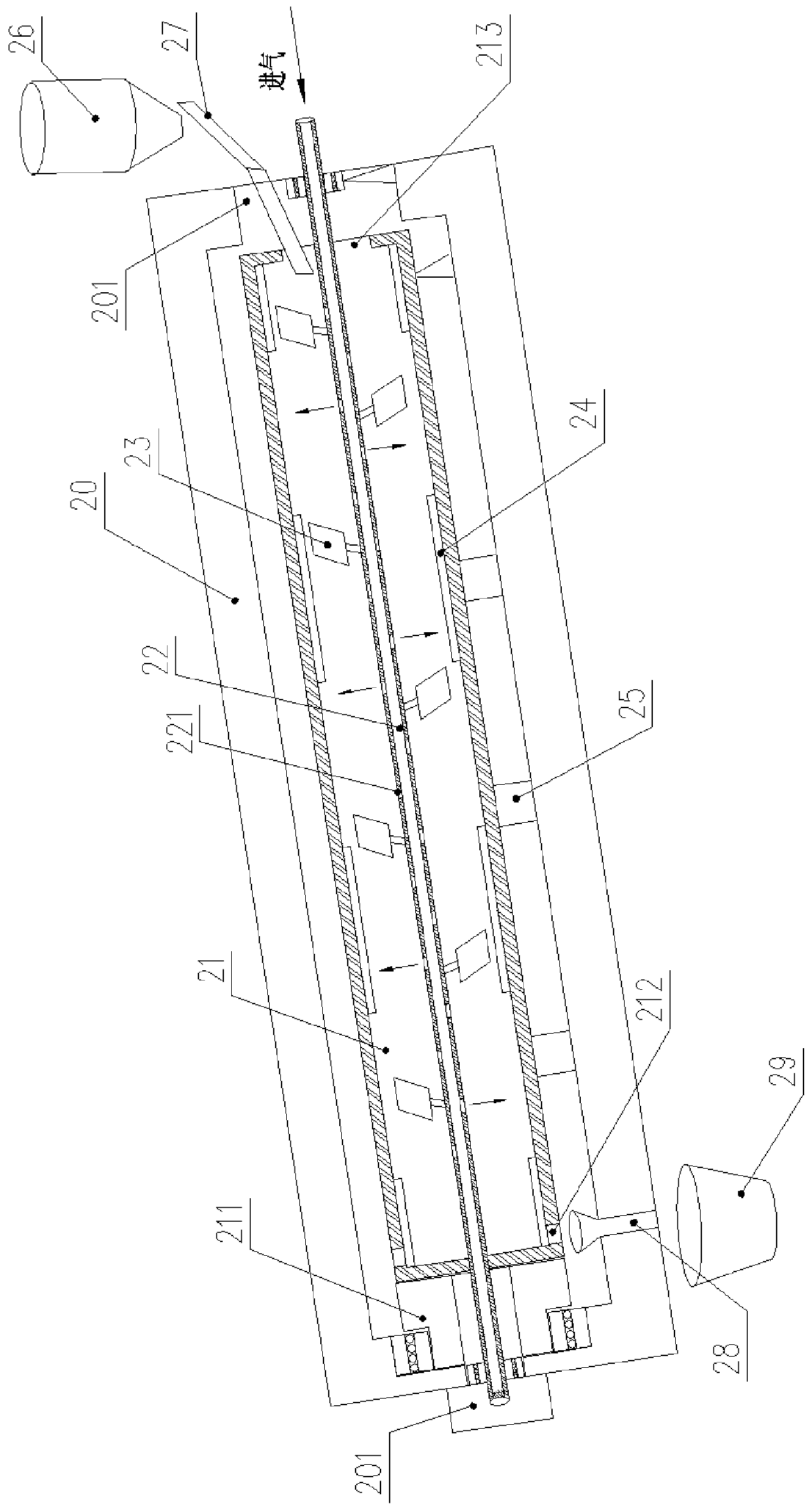

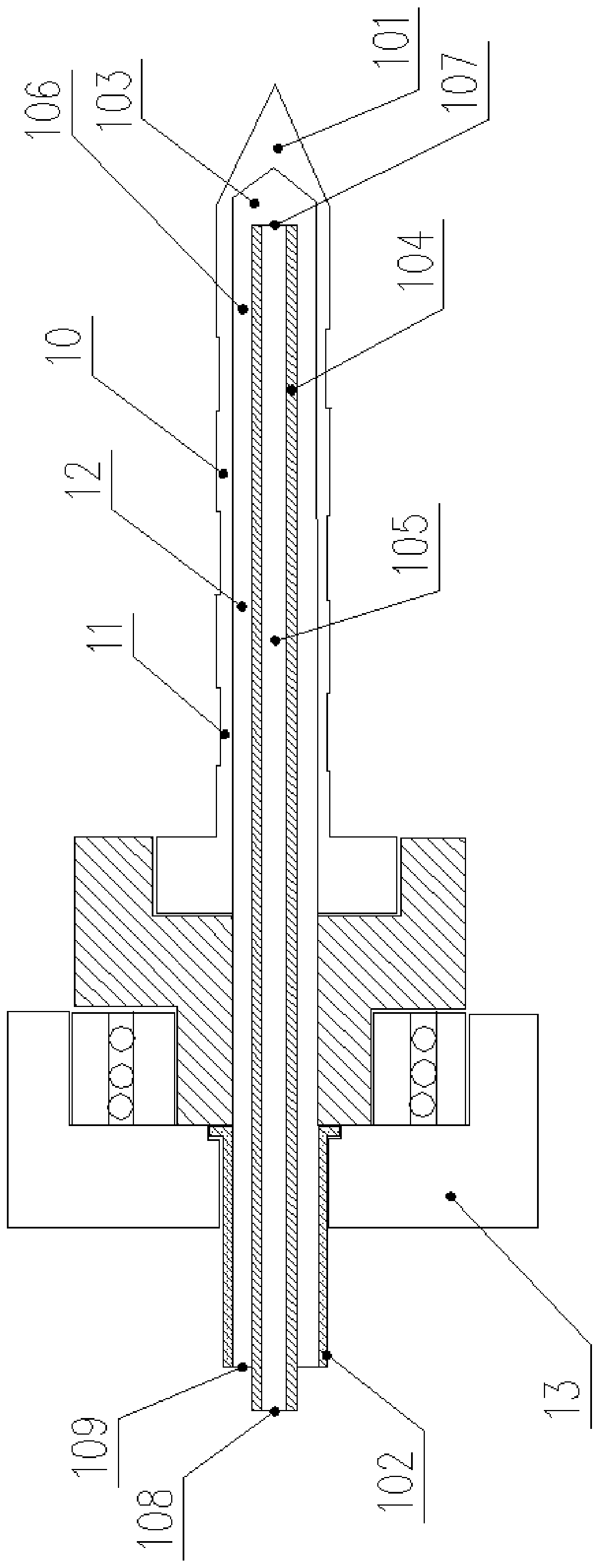

[0054]The amorphous nanocrystalline powder baking device includes a mounting bracket 20, and a heating furnace cavity 21 for heating and baking the amorphous nanocrystalline powder is arranged in the mounting bracket 20, and the heating furnace cavity 21 is heated by corresponding heating. The equipment is used to realize temperature-controlled heating in its cavity; the heating furnace cavity 21 is in the shape of a cylindrical barrel, and the heating furnace cavity 21 is coaxially arranged with the installation bracket 20; under the support of an external support, the heating The furnace cavity 21 and the mounting bracket 20 are arranged obliquely along the axial direction relative to the horizontal plane; the inclined lower side of the heating furnace cavity 21 is provided with a cavity outlet 212, and the position corresponding to the cavity outlet 212 is provided on the mounting bracket 20 A material receiving funnel 28, the discharge end of the material receiving funnel 2...

Embodiment 2

[0069] The amorphous and nanocrystalline powder baking device also includes an ultrasonic vibrator 25 installed on the mounting bracket 20 , and the ultrasonic vibrator 25 outputs ultrasonic waves into the heating chamber 21 .

[0070] The amorphous nanocrystalline powder baking device used in Example 2 involves the application of a second insulating coating method. Specifically, the second insulating coating method includes the following steps:

[0071] S4-21. Using ultrasonic waves to mix the inorganic powder and attach it to the amorphous mixed powder to obtain an amorphous attached powder;

[0072] S4-22. Mix the alkali solution with the amorphous adhesion powder and fully react, dry and fix with a binder, so that the surface of the amorphous adhesion powder is fixed to form an insulating coating layer, and the Amorphous coated powder.

[0073] The inorganic powder is SiO 2 or Fe 2 o 3 and other inorganic oxides; the mesh number of the inorganic powder is more than 800...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com