Bilateral thin-wall barrel port inward curling machine

A crimping machine and thin-walled technology, applied in the field of machinery and equipment, can solve the problems of low production efficiency, poor machining accuracy, and inability to mass-produce, and achieve the effects of reducing manpower usage, improving symmetry accuracy, and improving automation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

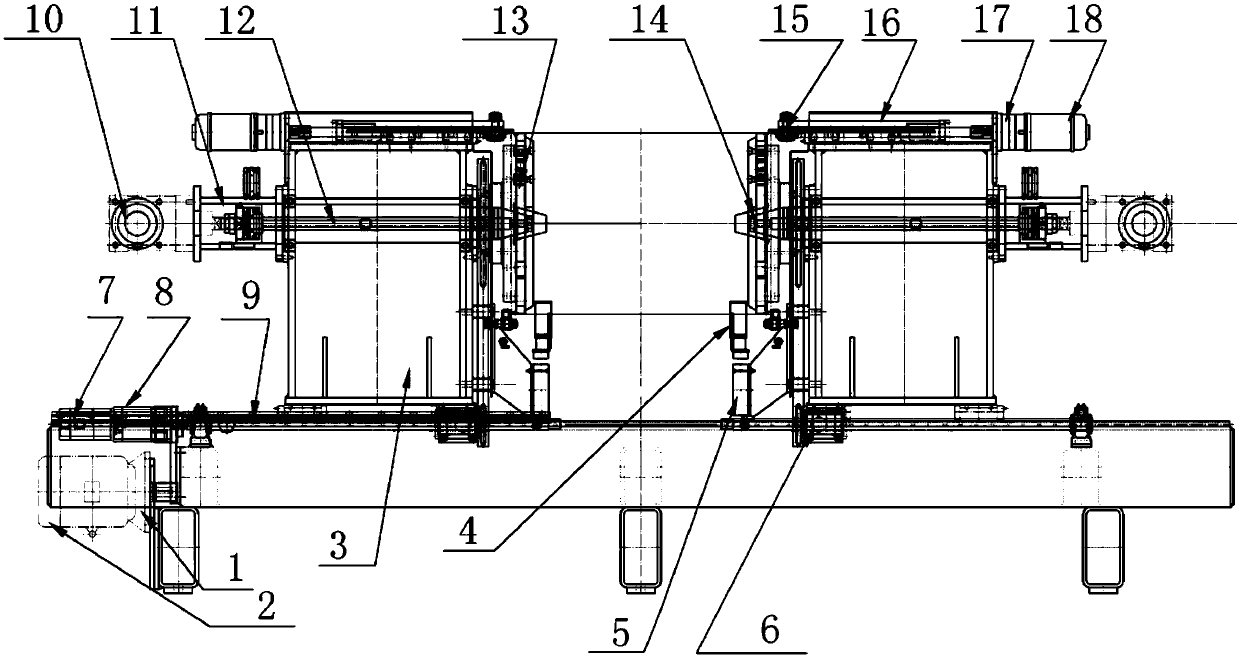

[0052] Such as figure 1 As shown, this application adopts a main body mechanism with relative movement of tooling boxes 3 on both sides of a reference working surface. The first motor 1 is installed on the left side of the application, and the first motor 1 is a servo motor; the first reducer 2 is installed On the right side of the first motor 1, the first reducer 2 is a planetary reducer; the hexagonal drive shaft is connected to the output hole of the first reducer 2 and runs through the bottom of the tooling box 3 on both sides, and the tooling box 3 on both sides Two sprockets 6 are arranged on the hexagonal transmission shaft at the bottom, and the sprocket 6 is fixedly connected with the bottom of the tooling box 3. The main movement of the workpiece forming is driven by the first motor 1 through the first reducer 2 to rotate the hexagonal transmission shaft. Each group of sprocket chain pairs of the workpiece boxes 3 on both sides transmits the torque to the workpiece p...

Embodiment 2

[0054] The displacement of the tooling box 3 on both sides of the application is realized by the linkage screw 9, the second motor 7 is installed above the first motor 1, and the model of the second motor 7 is ECMA-C20807RS; the second reducer 8 is installed on The right end of the second motor 7, the model of the second reducer 8 is PLF80-10; the left side of the linkage screw 9 is connected to the output hole of the second reducer 8 and runs through the bottom of the tooling box 3 on both sides, The linkage screw 9 is arranged on the front side of the hexagonal transmission shaft, and the two do not affect each other; the displacement of the tooling box 3 is driven by the second motor 7 through the second reducer 8 to rotate the linkage screw 9, and is installed on both sides of the linkage screw 9 The tooling box body 3 begins to move toward each other, and the sprocket wheel 6 fixedly installed on the bottom of the tooling box body 3 follows the tooling box body 3 displacem...

Embodiment 3

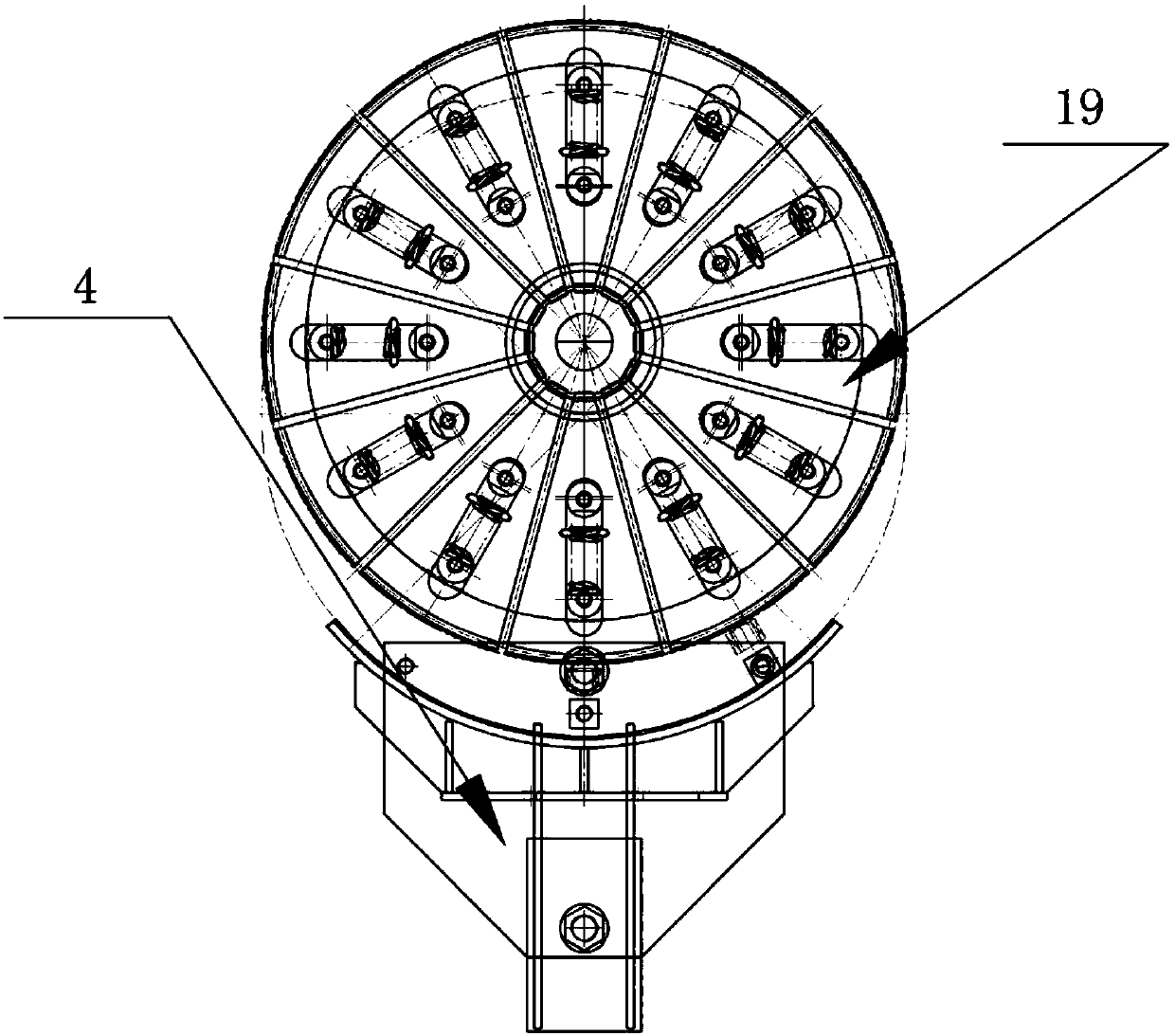

[0056] The core-pulling positioning mechanism 11 of the present application penetrates through the middle of the tooling box body 3, and the left and right core-pulling positioning mechanisms 11 are on the same axis. The core-pulling positioning mechanism 11 includes: a core-pulling cylinder 10 , a core-pulling rod 12 , and a core-pulling tower head 14 . The core-pulling cylinder 10 is located at the tail end of the core-pulling positioning mechanism 11. The model of the core-pulling cylinder 10 is SC150X50. The front end of the core-pulling cylinder 10 is provided with a core-pulling rod 12, which is installed inside the tooling box 3 , The front end of the core-pulling rod 12 is provided with a core-pulling tower head 14, the core-pulling tower head is provided with 12 expansion flaps 19, and the outer ring of the core-pulling tower head is provided with a workpiece positioning account plate 13. The loading and unloading positioning of the workpiece generates relative motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com