Nitrogen-doped mesoporous bamboo-based charcoal and application thereof

A technology of nitrogen doping and biochar, applied in the direction of alkali metal compounds, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of forming, limited specific surface area, poor pore structure, etc., and achieve the strength of finished products High, high desulfurization performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Specifically, nitrogen-doped mesoporous bamboo-based biochar is prepared by the following method:

[0033] A. Cut waste bamboo chopsticks into bamboo segments, wash and dry, and then carbonize at high temperature in an inert atmosphere to obtain carbonized materials;

[0034] B. The carbonized material is calcined at low temperature in an oxidizing atmosphere to obtain the oxidized material;

[0035] C. Mix the oxidizing material with the urea solution for ultrasonic impregnation, then dehydration, high-temperature calcination in an inert atmosphere, and then cooling, washing and drying to obtain nitrogen-doped mesoporous bamboo-based biochar.

[0036] The raw material of the present invention is waste disposable bamboo chopsticks, which has a wide range of sources. In order to directly obtain shaped biochar after calcination, it does not need to be reprocessed and shaped like powdered biochar to be directly put into industrial application. It is cut into bamboo sections with a...

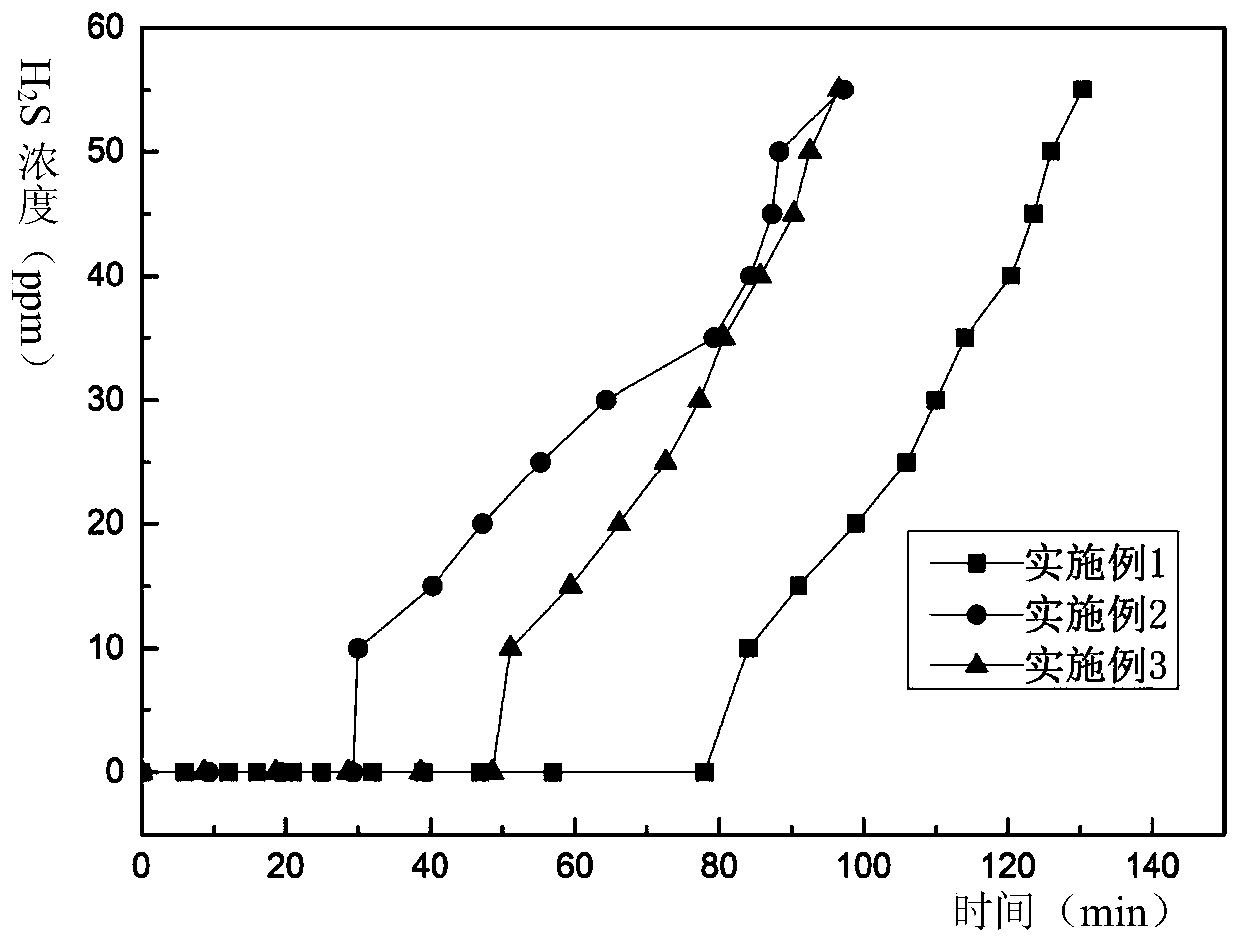

Embodiment 1

[0044] Cut the discarded bamboo chopsticks into bamboo segments with a length of about 1 cm and a diameter of about 0.5 cm, wash them with hot distilled water several times, put them in an oven, and dry them at 105°C for 24 hours. Weigh 40g of the pretreated bamboo section, place it in a tube furnace, and pass N at a flow rate of 150mL / min 2 30min in N 2 In the atmosphere, the temperature is increased to 800°C at a rate of 5°C / min, and carbonized for 2 hours to obtain a carbonized material;

[0045] Place the carbonized material in a tube furnace, blow in air at a flow rate of 150 mL / min, heat up from room temperature to 370 °C at a rate of 5 °C / min, and oxidize for 7 hours to obtain an oxidized material;

[0046] Dissolve urea in water and mix the urea solution with the oxidizing material at a mass ratio of 1:1. After ultrasonic immersion for 15 minutes, the suspension is evaporated to dryness at 80°C, and then the dehydrated sample is transferred to the tube In the furnace, at ro...

Embodiment 2

[0050] Cut the discarded bamboo chopsticks into bamboo segments with a length of about 1 cm and a diameter of about 0.5 cm, wash them with hot distilled water several times, put them in an oven, and dry them at 105°C for 24 hours. Weigh 40g of the pretreated bamboo section, place it in a tube furnace, and pass N at a flow rate of 150mL / min 2 30min in N 2 In the atmosphere, the temperature is increased to 800°C at a rate of 5°C / min, and carbonized for 2 hours to obtain a carbonized material;

[0051] Place the carbonized material in a tube furnace, blow in air at a flow rate of 150 mL / min, heat up from room temperature to 370 °C at a rate of 5 °C / min, and oxidize for 7 hours to obtain an oxidized material;

[0052] Dissolve urea in water and mix the urea solution with the oxidizing material at a mass ratio of 2:1. After ultrasonic immersion for 15 minutes, the suspension is evaporated to dryness at 80°C, and the dehydrated sample is transferred to the tube In the furnace, at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| breakthrough sulfur capacity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com