Infrared broadband cut-off filter, optical filter and camera

A cut-off filter and wide-band technology, applied in the field of optical film, can solve the problem of narrow cut-off width of infrared cut-off filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Simulation experiment data:

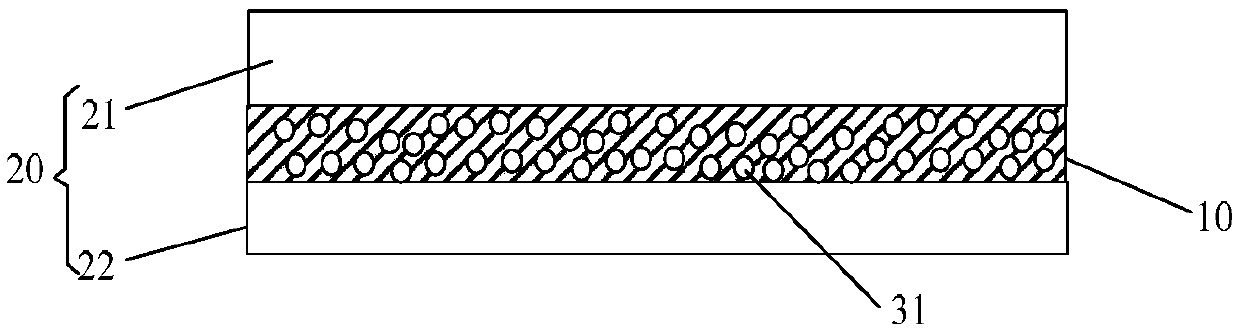

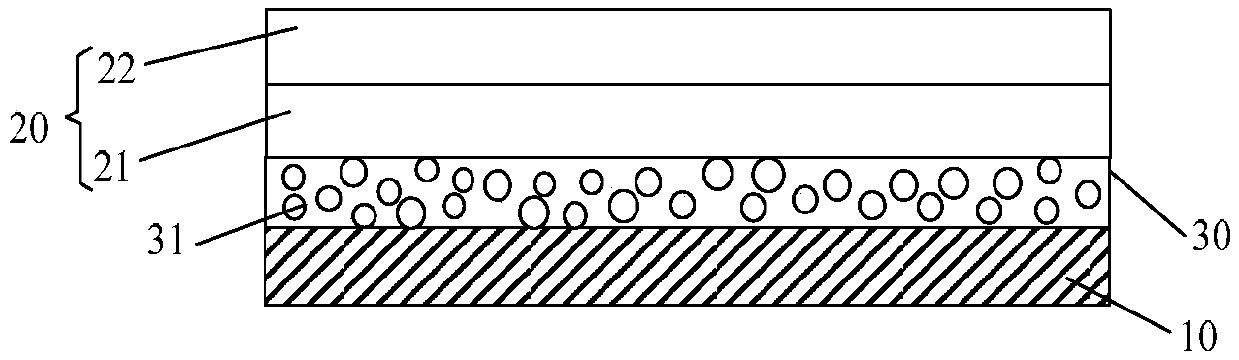

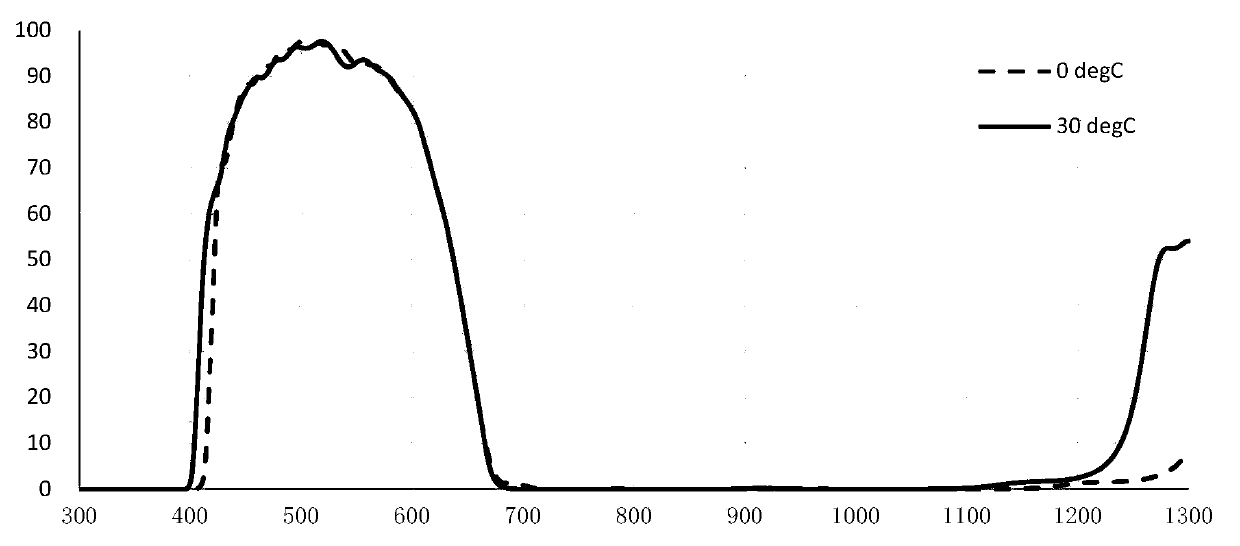

[0061] Infrared broadband cut-off filter structure such as figure 1 As shown, the transparent substrate layer is a PET layer doped with a light absorber, the high refractive index material layer forming the cut-off unit is a titanium dioxide layer with a refractive index of 2.354, and the low refractive index material layer is silicon dioxide with a refractive index of 1.46. Layer, the transparent substrate layer is provided with light absorber ABS-642, and uv-531 (2-hydroxyl-4-n-octyloxybenzophenone) ultraviolet light absorber, light absorber ABS-642 is in this transparent The weight percentage in the base material layer is about 1%, and the weight percentage of the uv-531 (2-hydroxy-4-n-octyloxybenzophenone) ultraviolet light absorber in the transparent base material layer is about 1%. Due to the addition of the above-mentioned ultraviolet absorber, when the shift is performed at 0-30°, the shift amount of the UV side spectrum can be con...

Embodiment 2

[0067] The infrared wide-band cut-off filter corresponding to Example 1 was manufactured by magnetron sputtering process, and the substrate (with a PET layer of 0.05mm on the substrate) was cleaned with a clean cloth and ethanol. After degassing the vacuum chamber, use a vacuum cleaner to clean the inside of the bell jar, fill the molybdenum boat with the film material to be evaporated, and record the name of the film material of each boat. And place the substrate on the substrate frame, do not tilt the substrate. Drop the bell jar and evacuate the vacuum chamber according to the operation rules of the coating machine. When the vacuum reaches 7×10 -3 After Pa, pre-melt the film material in the molybdenum boat in turn to remove the gas in the film material. At this time, pay attention to block the film material with a baffle to ensure that the substrate will not be plated during pre-melting. When the vacuum degree reaches the requirement, the method of controlling the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com