Device for testing heat conductivity coefficient and contact thermal resistance of gas diffusion layer in compressed state

A gas diffusion layer and thermal conductivity technology, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of large size, complex structure, and measurement error of operating instruments, and achieve easy disassembly and assembly, high thickness measurement accuracy, and assembly and the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

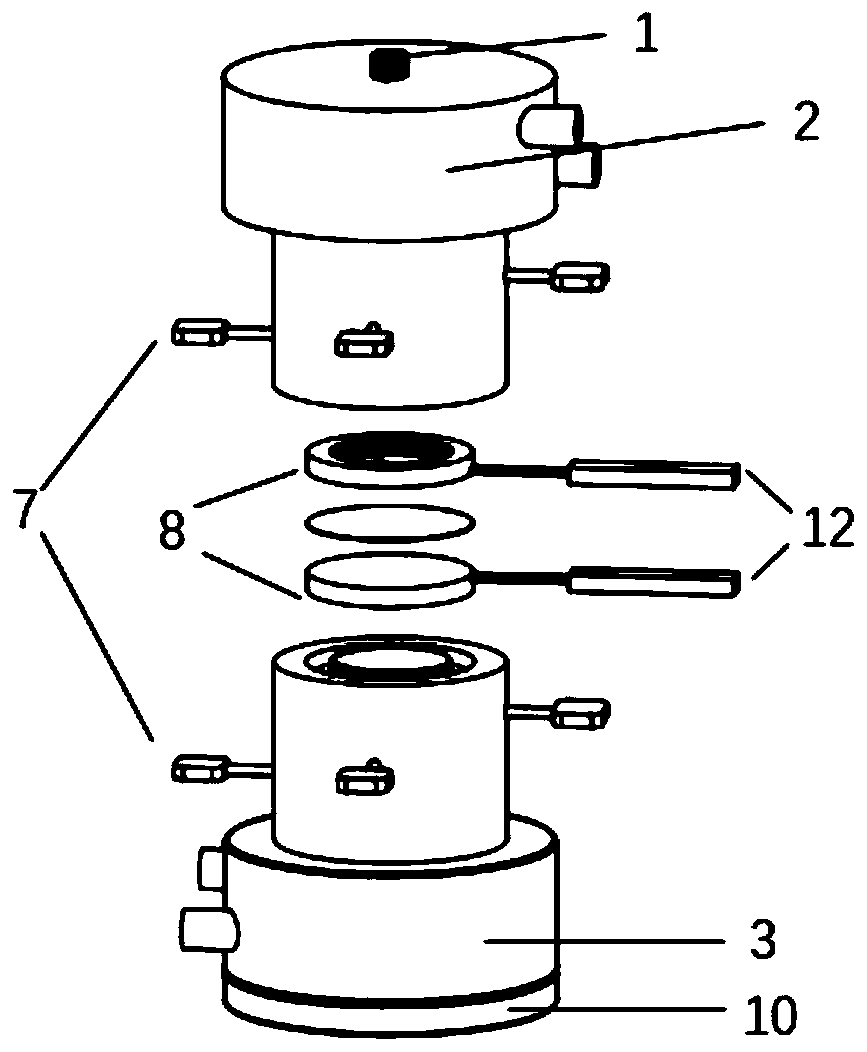

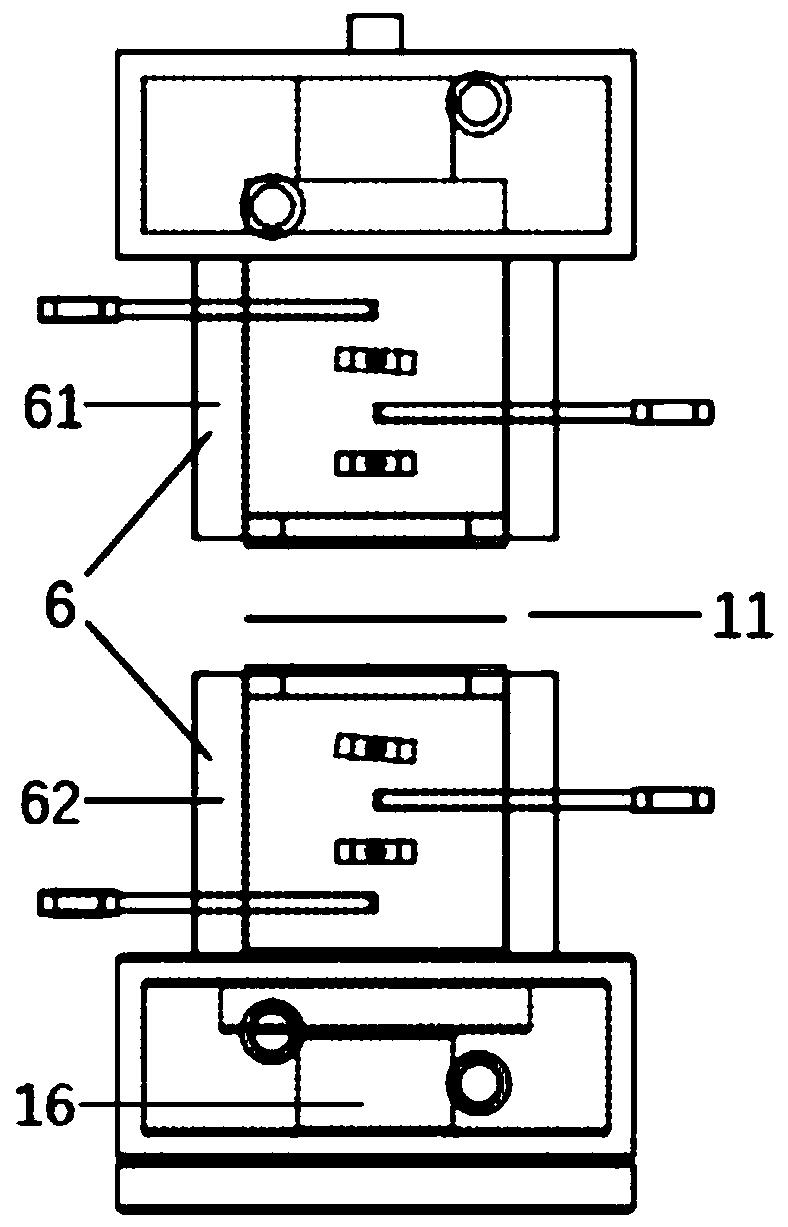

[0067] like Figure 1-5 As shown, a test device that can test the thermal conductivity and contact thermal resistance of the gas diffusion layer in the compressed state. The effective thermal conductivity of the gas diffusion layer under different pressures and the contact thermal resistance between the gas diffusion layer and bipolar plates of different materials can be tested by using the testing device. The test device is designed based on the test method of steady-state heat flow method. The testing device is mainly used in conjunction with the universal testing machine, and can be assembled on the universal testing machine to provide the required pressure in the testing process through the universal testing machine. The universal testing machine is a prior art, not shown in the figure. The testing device is equipped with an extensometer 12, which can measure the deformation of the sample thickness under different pressures. The heat flow passing through the sample is re...

Embodiment 2

[0076] Different from Embodiment 1, the cooling medium and the heat exchange medium in this embodiment are both ethylene glycol. The material of the upper heat flow column 4 and the lower heat flow column 5 is electrolytic iron. The upper heat flow column 4 and the lower heat flow column 5 have a temperature measuring circular hole with a diameter of 1mm every 10mm along the axial direction. Both the upper heat flow column 4 and the lower heat flow column 5 are processed with external threads on the sides at a distance of 6 mm from their end faces.

[0077] In this embodiment, the thickness of the replaceable test head 8 is 1 mm, and there is a temperature measuring groove 0.5 mm away from the upper end surface of the replaceable test head 8, and the material of the replaceable test head 8 is carbon-plated metal.

[0078] In this embodiment, the material of the thermal insulation pad 10 and the thermal insulation cover 6 is asbestos. The length of the heat insulating cover 6...

Embodiment 3

[0080] A test device for thermal conductivity and thermal contact resistance of a gas diffusion layer in a compressed state, the specific structure of which is as follows Figure 1-4As shown, the device can be used in conjunction with a universal testing machine, which provides the required pressure during the test. During the test, select the test head made of the material that needs to measure the contact thermal resistance, screw the two test heads on the end faces of the upper heat flow column 4 and the lower heat flow column 5 respectively, and the interface between the test head and each heat flow column end surface needs to be in good thermal contact , to ensure that the heat flow can be completely transferred to the test head. Insert the miniature thermocouple 9 into the temperature measuring tank of each test head, and use silica gel to seal the temperature measuring tank to fix the miniature thermocouple 9 to prevent the miniature thermocouple 9 from falling during t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com