A method of testing photoresist resin components

A photoresist and resin technology, which is applied in the direction of weighing, analyzing materials, and measuring devices by removing certain components, can solve problems such as inability to analyze, difficult to dissolve resin, and displacement, so as to save solvent consumables and atlases Clear and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The methacrylate monomers A and B are polymerized by the method of the present invention according to the design molar ratio of the monomers being 50:50 to obtain a photoresist resin.

[0039] The numerical value of the photoresist was analyzed by nuclear magnetic resonance technology, and the hydrogen spectrum and carbon spectrum were obtained. It was found that the monomer peaks in the spectrum were easy to overlap or interfere with each other, and it was not easy to obtain the actual molar ratio of the monomer through the peak area.

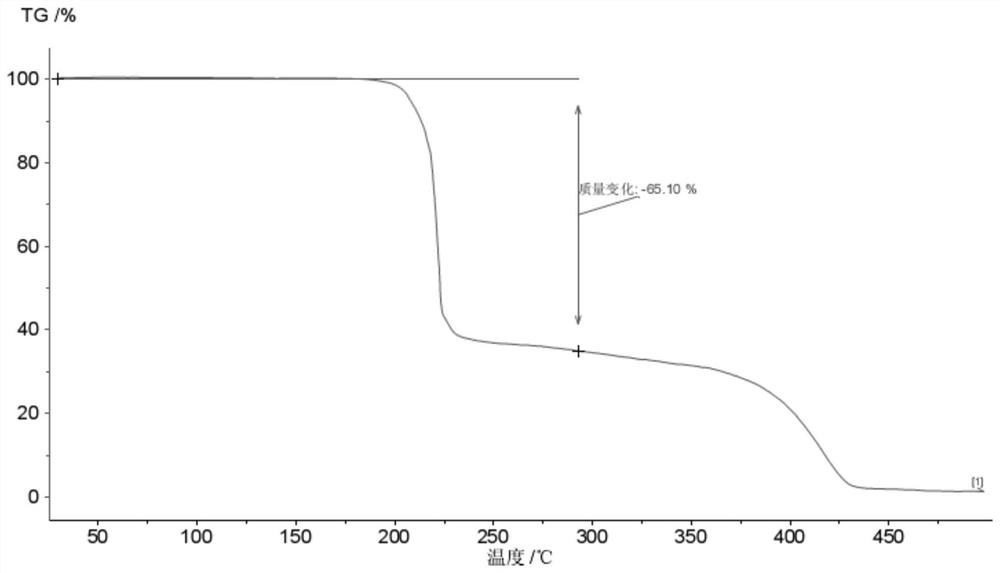

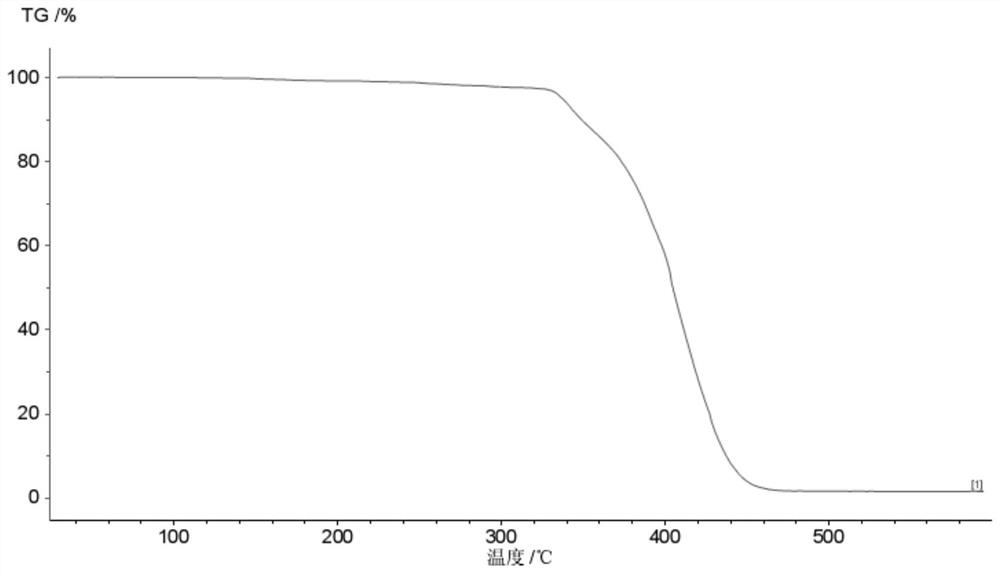

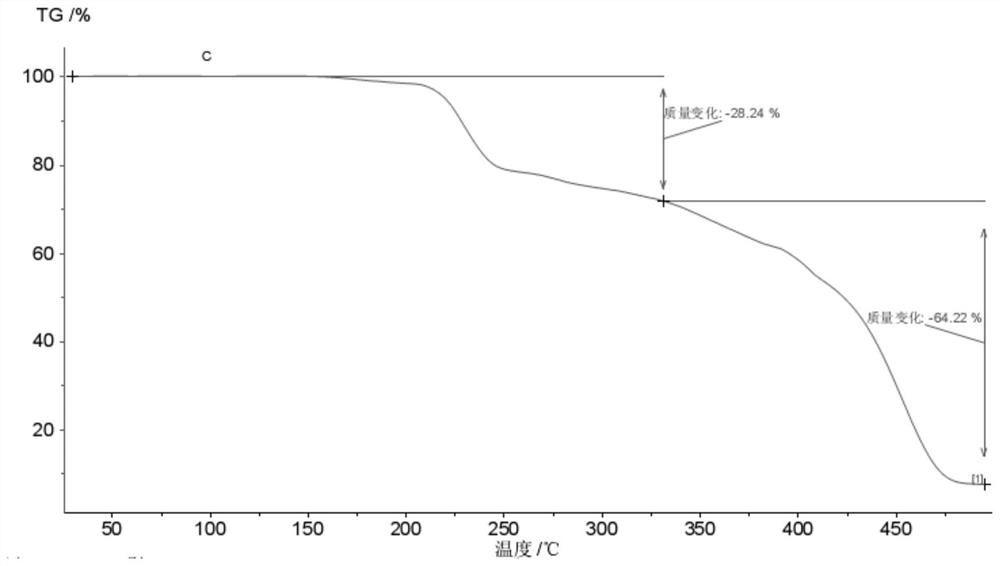

[0040] Thermogravimetric analysis was performed on monomer A, monomer B, and photoresist values respectively. The instrument used NETZSCH STA449F5 thermal analyzer (Shanghai Nachi Co., Ltd.), the test temperature was 500°C, the heating rate was 20k / min, and the nitrogen protection was 20ml / min ,get figure 1 , figure 2 with image 3 .

[0041] Depend on figure 1 , 2 It can be seen that monomer A begins to decompose at 200°C, and ...

Embodiment 2

[0050] The methacrylate monomers A and B are polymerized by the method of the present invention according to the design molar ratio of the monomers being 70:30 to obtain a photoresist resin.

[0051] The numerical value of the photoresist was analyzed by nuclear magnetic resonance technology, and the hydrogen spectrum and carbon spectrum were obtained. It was found that the monomer peaks in the spectrum overlapped with each other, and the actual molar ratio of the monomer could not be calculated by the peak area.

[0052] Thermogravimetric analysis was performed on monomer A, monomer B, and photoresist values respectively. The instrument used NETZSCH STA449F5 thermal analyzer (Shanghai Nachi Co., Ltd.), the test temperature was 500°C, the heating rate was 20k / min, and the nitrogen protection was 20ml / min ,get Figure 4 , Figure 5 with Image 6 .

[0053] Depend on Figure 4 , 5 It can be seen that monomer A starts to decompose from 200°C, monomer B starts to decompose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com