Pipeline steel welding residual stress prediction method based on ANSYS

A residual stress and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low X-ray penetration, high cost, affecting the accuracy of residual stress measurement, and achieve high analysis efficiency. , saving manpower and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

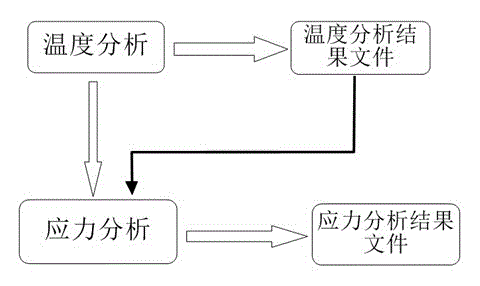

[0028] A method for predicting welding residual stress of X80 pipeline steel based on ANSYS finite element analysis software, comprising the following steps:

[0029] Step (1): Determine the welding conditions, the conditions are: double wire submerged arc welding front wire: I=750A, U=40V; rear wire: I=600A, U=40V; the distance between the front and rear wires is 40mm, and the welding speed is 12mm / s, weldment length 300mm, width 160mm, thickness 20mm;

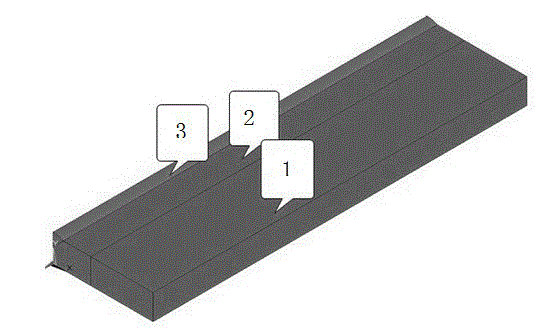

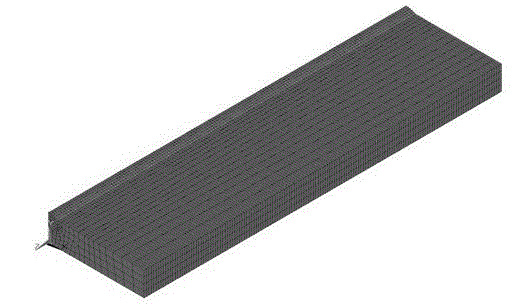

[0030] Step (2): Create a solid model of the weldment and define a SOLID70 unit to sweep and divide the grid; the grid size of the weld area is 2mm, and the heat-affected zone and the base metal area are divided in proportion to the line first, and then swept; the overall It conforms to the rule that the farther away from the weld, the larger the grid size; when the model is a symmetrical model, in order to reduce the amount of calculation, the half plate can be selected for analysis;

[0031] Enter the solution process bel...

Embodiment 2

[0035] A method for predicting welding residual stress of X80 pipeline steel based on ANSYS finite element analysis software, comprising the following steps:

[0036] Step (1): Determine the welding conditions, the conditions are: the welding current of single wire submerged arc welding is 650A, the welding voltage is 40V, and the welding speed is 12mm / s. The weldment is 300mm long, 160mm wide and 20mm thick;

[0037] Step (2): Create a solid model of the weldment, and define a SOLID70 unit to sweep and divide the mesh. Among them, the grid size of the weld area is 2mm, and the heat-affected zone and the base metal area are divided in proportion to the line first, and then swept; the overall conforms to the rule that the farther away from the weld, the larger the grid size, when the model is a symmetrical model , in order to reduce the amount of calculation, the half plate can be selected for analysis;

[0038] Enter the solution process below to calculate the temperature fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com