Pressure sensitive element resistant to high temperature particle erosion and its preparation method and sputtered thin film pressure sensor

A technology of sensitive components and high temperature resistance, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve problems such as narrow operating temperature range, insufficient temperature shock resistance and life, failure of pressure sensitive components, etc., to improve reliability and Effects of service life, strong washout/shock resistance, good reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

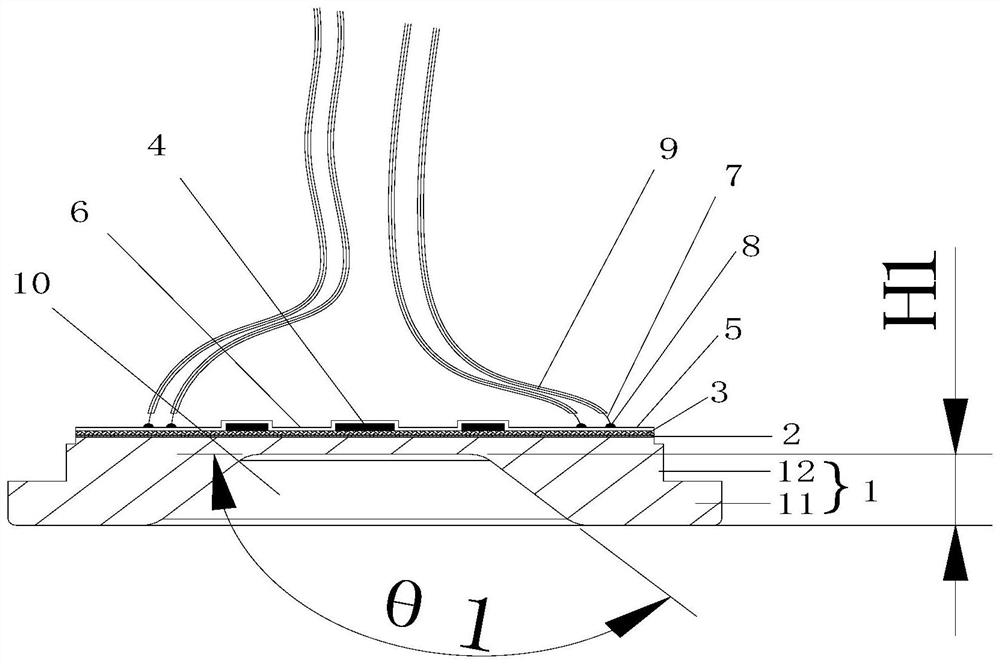

[0043] A pressure sensitive element resistant to high temperature particle erosion, such as figure 1 As shown, it includes an elastic base material 1; the elastic base material 1 is a flaring convex elastic body structure, including a pressurized chamber 10, a body 11 and a mounting part 12; the mounting part 12 is sequentially provided with a transition layer 2, an insulating layer 3, Resistive film layer 4, passivation layer 5, metal layer 6, wherein the elastic base material 1 has a linear expansion coefficient of 6.9×10 at a temperature of -60°C to 600°C -6 / K~8.3×10 -6 / K high temperature alloy, the insulating layer is Al 2 o 3 .

[0044] In this embodiment, the angle θ1 between the top surface and the side surface of the pressurized chamber 10 is 135°, and the depth H1 of the pressurized chamber 10 is 3.25 mm.

[0045] In this embodiment, the elastic base material 1 is 4J33 alloy (commercially available).

[0046] In this embodiment, the transition layer 2 is NiSiAL...

Embodiment 2

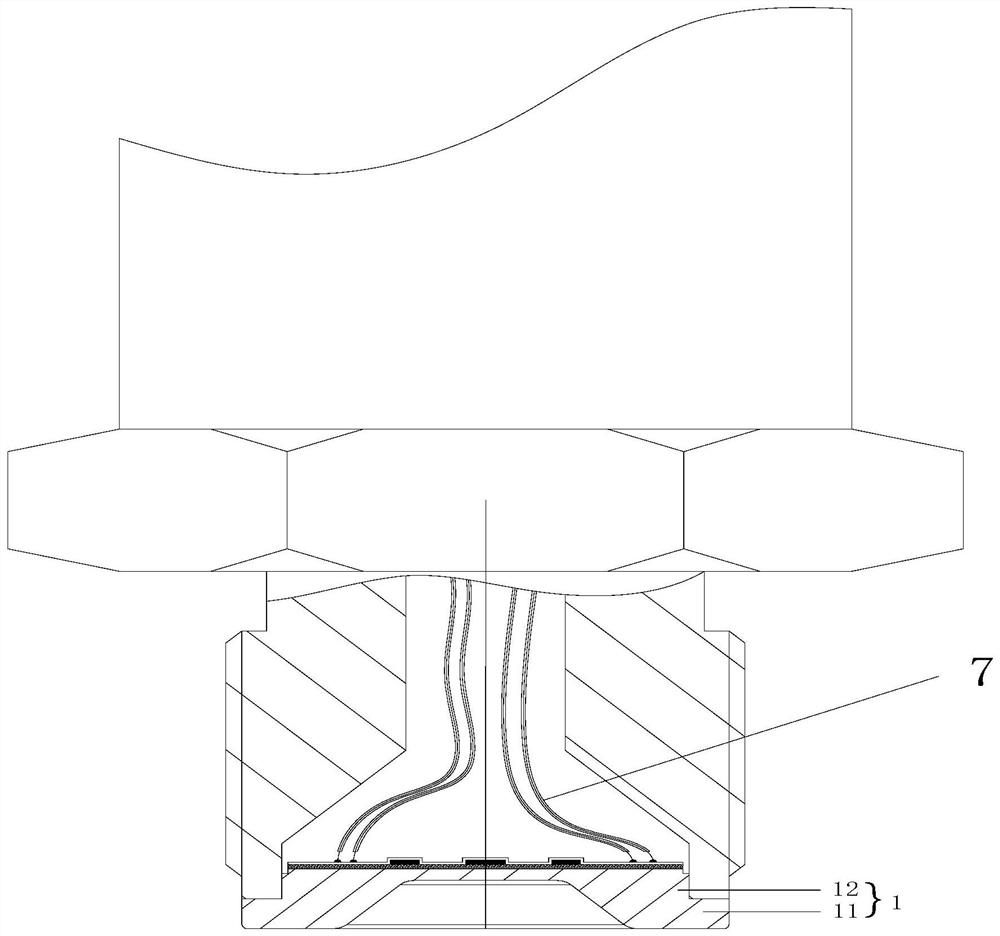

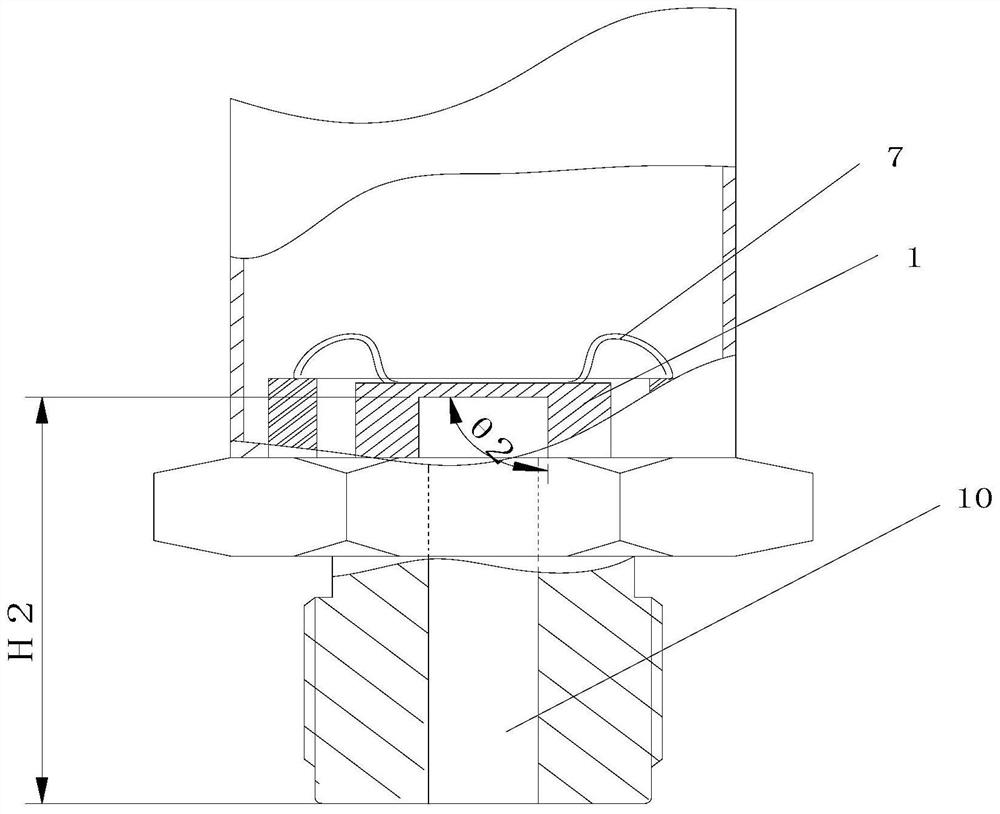

[0058] A sputtered thin-film pressure sensor resistant to high-temperature particle erosion, such as figure 2 As shown, it includes a hollow shell and the pressure sensitive element in Example 1.

[0059] In this embodiment, the hollow shell is fixed to the pressure sensitive element through the mounting part 12, and the transition layer 2, the insulating layer 3, the resistive film layer 4, the passivation layer 5 and the metal layer 6 on the mounting part 12 are arranged in the hollow shell Inside the body, the main body 11 is located outside the hollow shell, and the lead wire 7 is drawn out from the inside of the hollow shell, where the mounting part 12 and the hollow shell are fixed by welding (laser welding, argon arc welding or electron beam welding are all acceptable) .

[0060]In this embodiment, the sputtering thin-film pressure sensor resistant to high-temperature particle erosion includes a hollow shell and a pressure-sensitive element. The pressure-sensitive ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com