High-level pool, water supply main pipeline and water receiving pipe network connecting structure and construction method

A construction method and water pipe network technology, applied in the direction of infrastructure engineering, water supply equipment, water supply main pipeline, etc., can solve the problems of difficult transportation, increased operating costs, and long distances for laying pipes, so as to ensure controllability and stability , Reduce the difficulty of operation management and save the operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

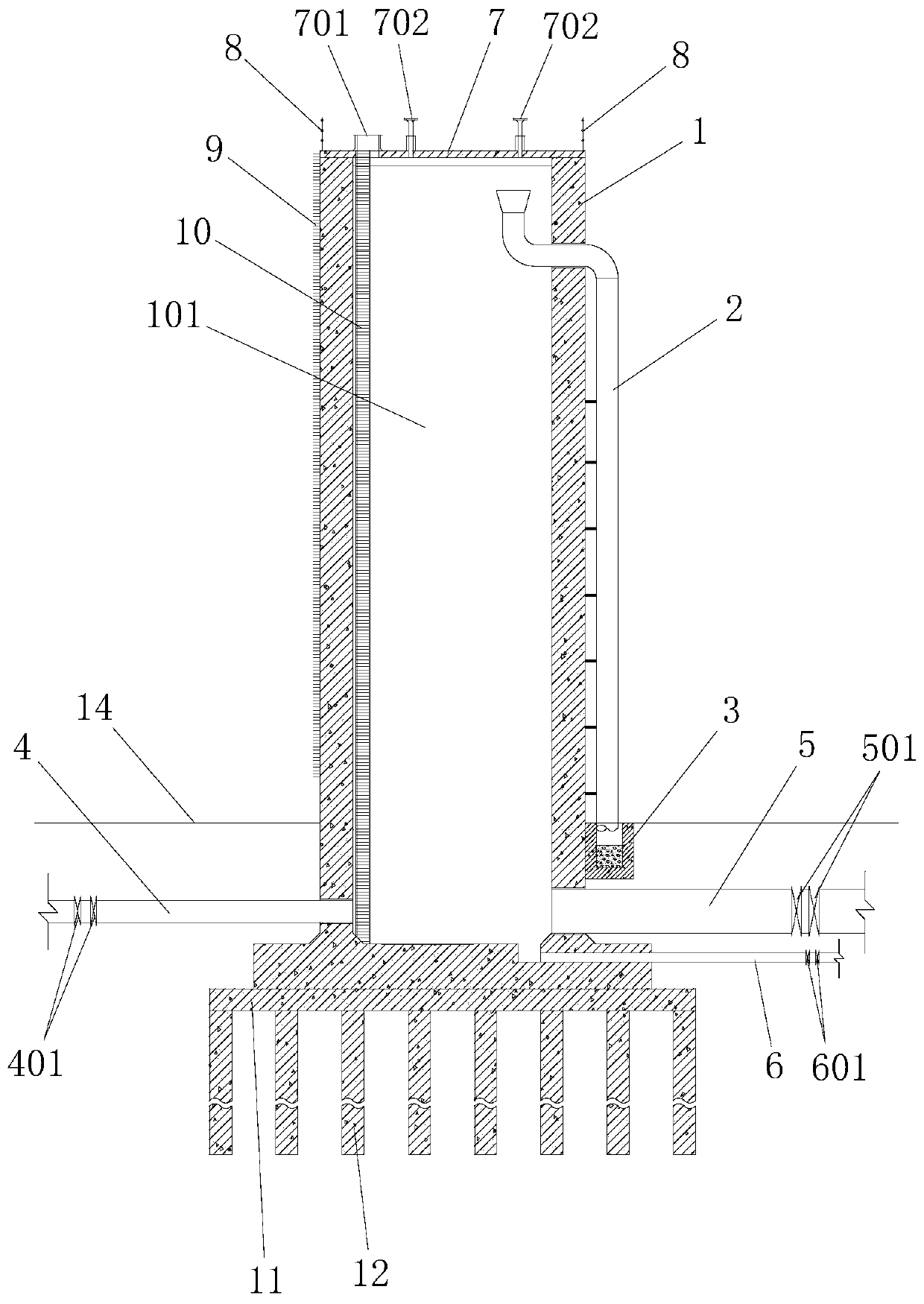

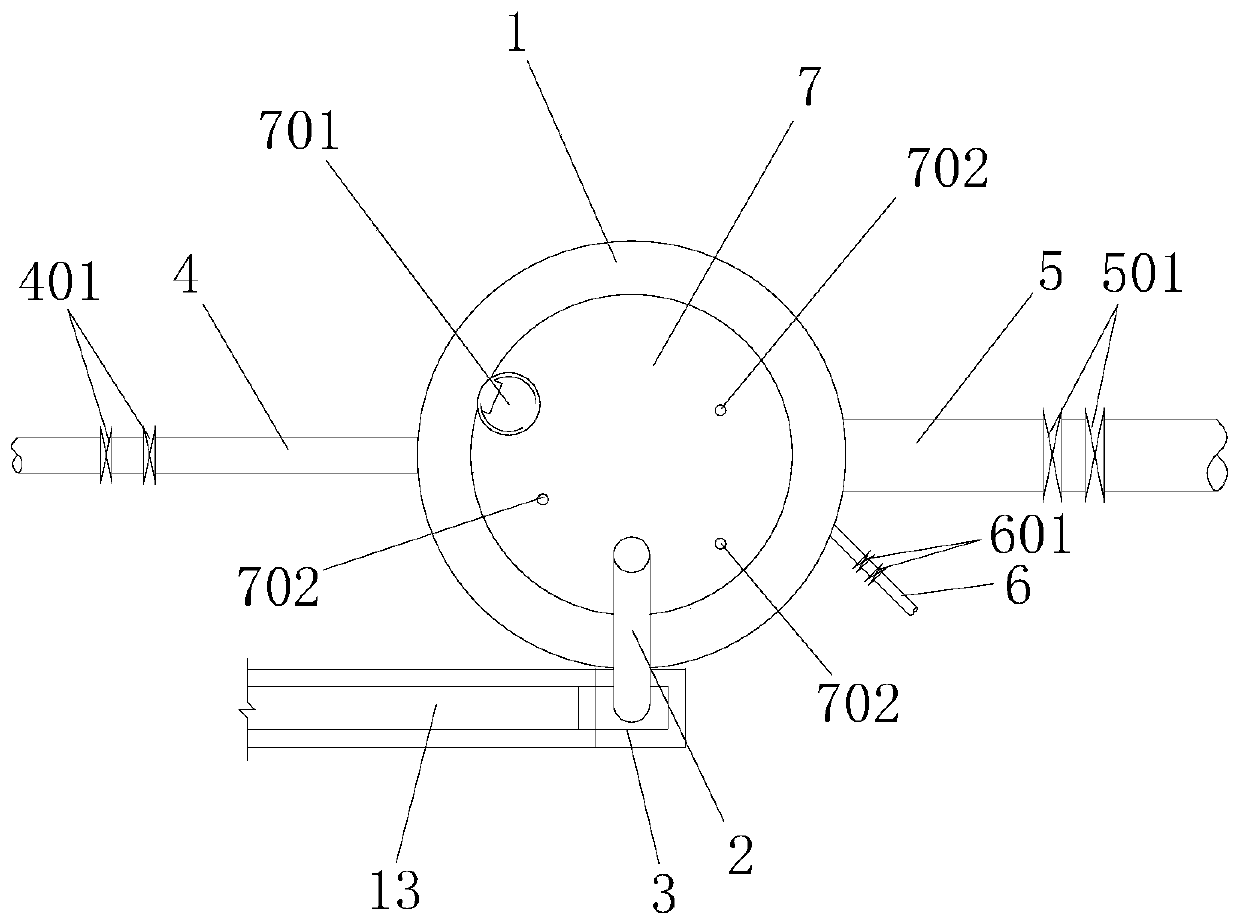

[0052] Such as figure 1 , figure 2 As shown, the present invention provides a high-level pool, which includes a pool body 1, wherein: a water-holding chamber 101 is formed inside the pool body 1, and an overflow pipe 2 is fixedly arranged on the outer wall of the pool body 1, and the overflow The top of the flow pipe 2 passes through the side wall of the pool main body 1 and extends into the water chamber 101. An overflow threshold line can be pre-marked on the upper inner wall of the water chamber 101. The top of the overflow pipe 2 is in the The inside of the water chamber 101 extends upwards to the same height as the overflow threshold line, and the outer lower part of the pool body 1 is provided with a drain channel 13 , and the bottom end of the overflow pipe 2 is connected to the drain channel 13 . The lower part of the pool main body 1 is provided with a first water delivery pipe 4 and a second water delivery pipe 5, one end of the first water delivery pipe 4 is fixed...

Embodiment 2

[0073] The present invention provides a connection structure between the main water supply line and the water receiving pipe network. The water delivery pipe 4 is connected, and the water receiving pipe network is connected with the second water delivery pipe 5 at the lower part of the elevated pool.

[0074] The characteristics and advantages of the connection structure between the main water supply line and the water receiving pipe network of the present invention are:

[0075] In the connection structure between the main water supply line and the water receiving pipe network, a high-level pool is used to connect the pipes on both sides, and the water is transferred and temporarily stored through the high-level pool, which can not only save costs, but also adjust the pressure in the water pipeline to ensure the stability of water supply. It can greatly reduce the impact of the water pipe network on the main line of the water supply supporting project, and at the same time re...

Embodiment 3

[0077] The invention provides a construction method for connecting a main water supply line and a water receiving pipe network. The construction method for connecting a main water supply line and a water receiving pipe network includes the following steps:

[0078] Step S1: Measure the scope and position of the foundation pit, and mark the excavation line, using 1.6m 3 The backhoe excavates the earthwork within the scope of the excavation line, retains the excavated material, and transports the excavated material to the excavated material storage yard along the line in a 15t dump truck for later backfilling;

[0079] Step S2: Clean up the debris in the foundation pit, drain the accumulated water, backfill the foundation pit with medium coarse sand, earthwork and gravel in sequence, and perform compaction treatment on the coarse sand, earthwork and gravel respectively;

[0080] Step S3: According to the engineering geology, adopt pile foundation reinforcement treatment in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com