Permeable asphalt and preparation method thereof

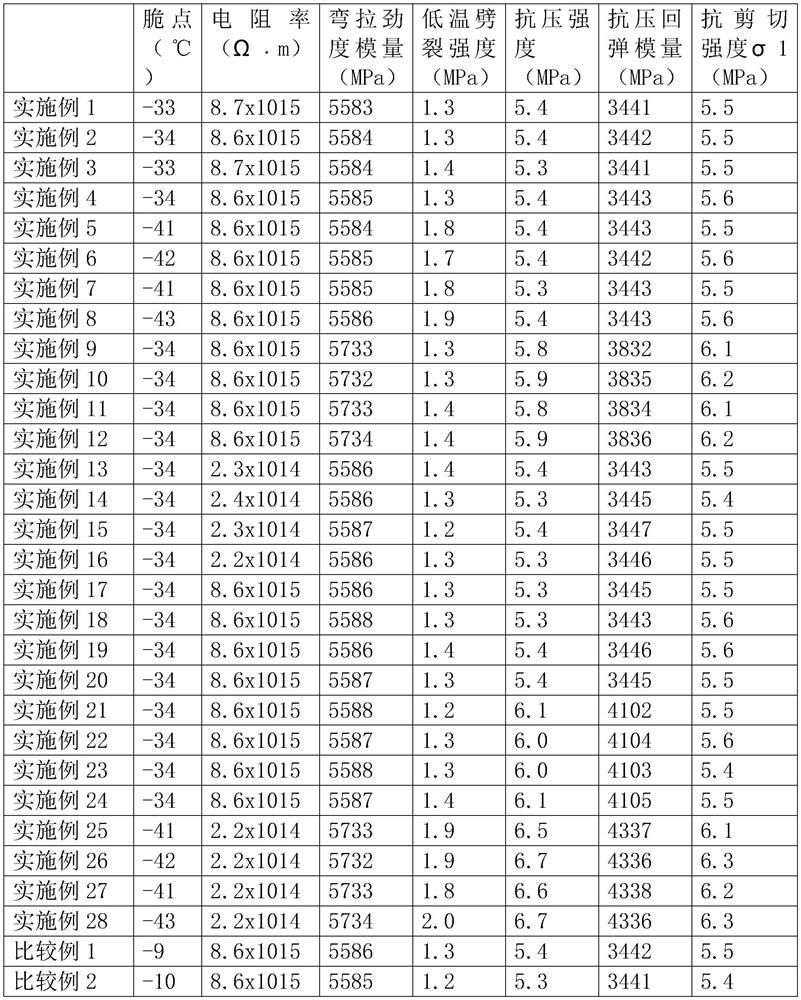

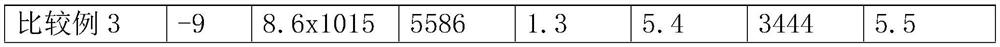

A technology of permeable asphalt and asphalt, which is applied in the field of permeable asphalt and its preparation. It can solve the problems of general frost resistance of asphalt, decrease in structural strength, and affect the use of road surfaces, and achieve the effects of reducing electrostatic hazards, increasing conductivity, and reducing brittle points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

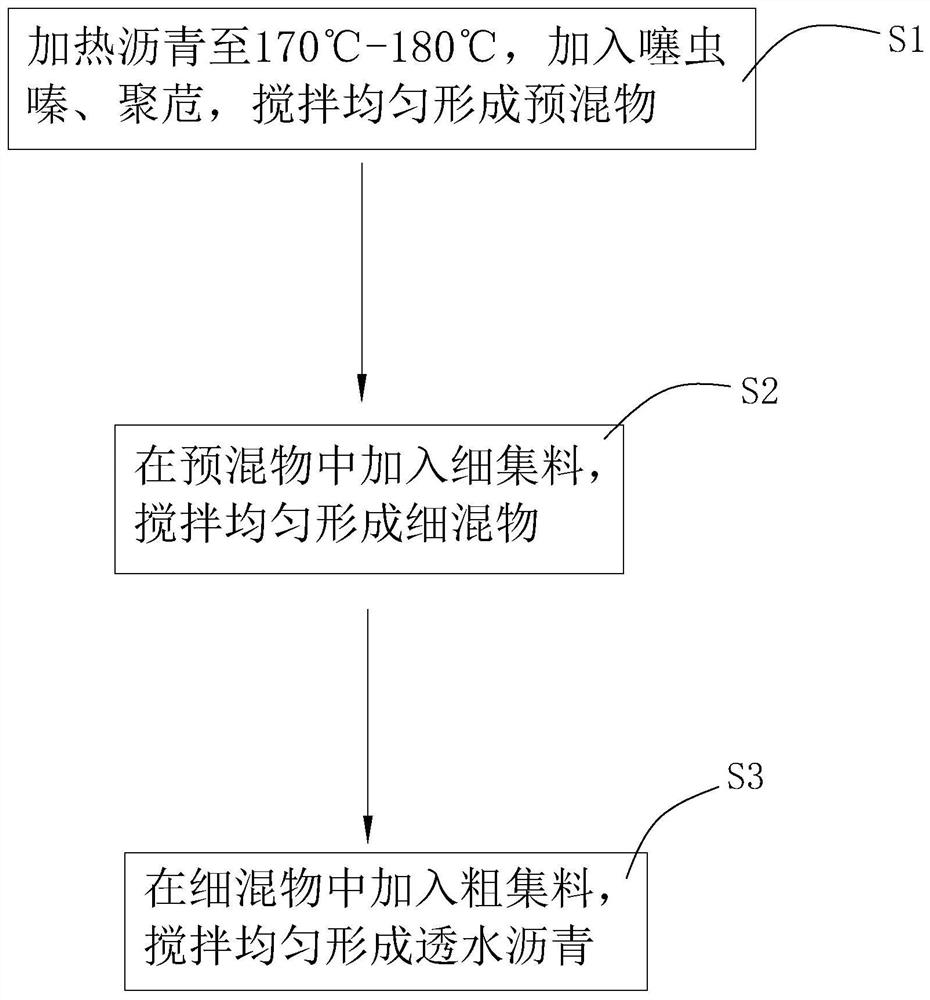

[0069] A kind of permeable asphalt, refer to figure 1 , the preparation method of permeable asphalt is as follows:

[0070] S1. Add 100kg of asphalt into the stirring tank, heat to 170°C, add 3kg of thiamethoxam and 0.5kg of polyacenaphthylene, keep the temperature at 170°C, rotate at 60r / min, and stir for 5min to form a premix.

[0071]S2. Add 90kg of fine aggregate to the premix, keep the temperature at 170°C, rotate at 55r / min, and stir for 5min to form a fine mixture;

[0072] S3. Add 380kg of coarse aggregate to the fine mixture, keep stirring at a constant temperature of 170°C and a rotating speed of 45r / min for 8 minutes to form permeable asphalt.

Embodiment 2

[0074] A kind of permeable asphalt, refer to figure 1 , the preparation method of permeable asphalt is as follows:

[0075] S1. Add 100kg of asphalt into the stirred tank, heat to 175°C, add 4kg of thiamethoxam and 1kg of polyacenaphthylene, keep the temperature at 175°C, rotate at 60r / min, and stir for 5min to form a premix.

[0076] S2. Add 105kg of fine aggregate to the premix, keep the temperature at 175°C, rotate at 55r / min, and stir for 5min to form a fine mixture;

[0077] S3. Add 395kg of coarse aggregate to the fine mixture, keep stirring at a constant temperature of 175°C and a rotating speed of 45r / min for 8 minutes to form permeable asphalt.

Embodiment 3

[0079] A kind of permeable asphalt, refer to figure 1 , the preparation method of permeable asphalt is as follows:

[0080] S1. Add 100kg of asphalt into the stirred tank, heat to 180°C, add 5kg of thiamethoxam and 1.5kg of polyacenaphthylene, keep the temperature at 180°C, rotate at 60r / min, and stir for 5min to form a premix.

[0081] S2. Add 120kg of fine aggregate to the premix, keep the temperature at 180°C, rotate at 55r / min, and stir for 5min to form a fine mixture;

[0082] S3. Add 410kg of coarse aggregate to the fine mixture, keep stirring at a constant temperature of 180°C and a rotating speed of 45r / min for 8 minutes to form permeable asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com