High-energy-saving sewage multi-layer percolation purification treatment method

A purification treatment and percolation technology, which is applied in the field of environmental engineering, can solve problems such as strict requirements on the concentration of suspended particulate matter in influent water, reduced pollutant removal rate, and difficulty in meeting water quality standards, achieving pollution-free discharge, high ornamental value, and saving infrastructure. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

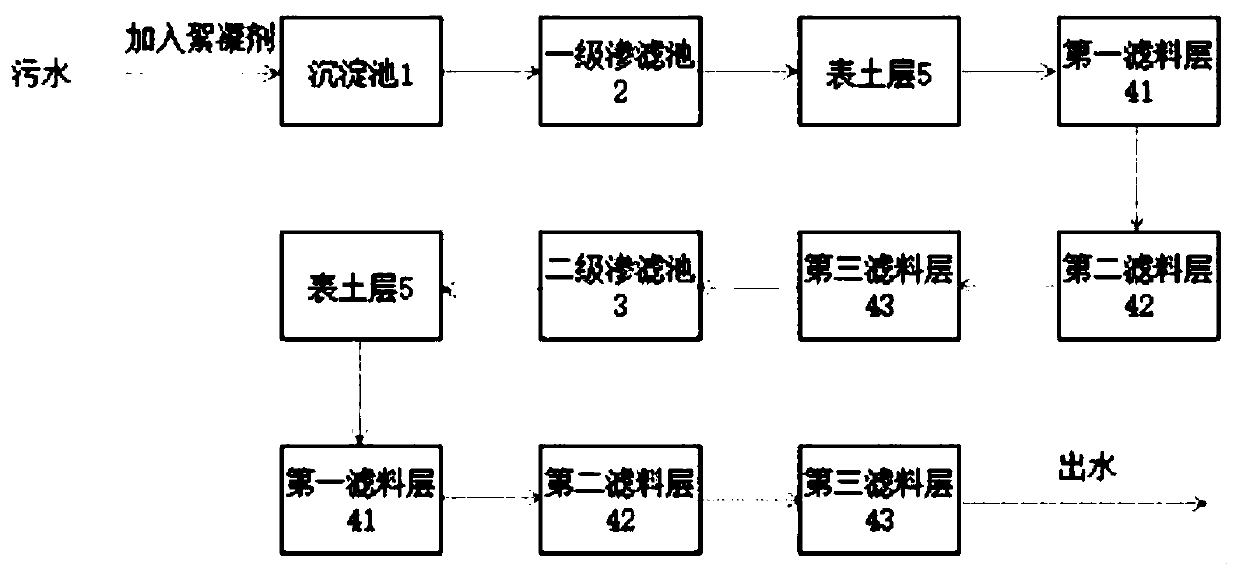

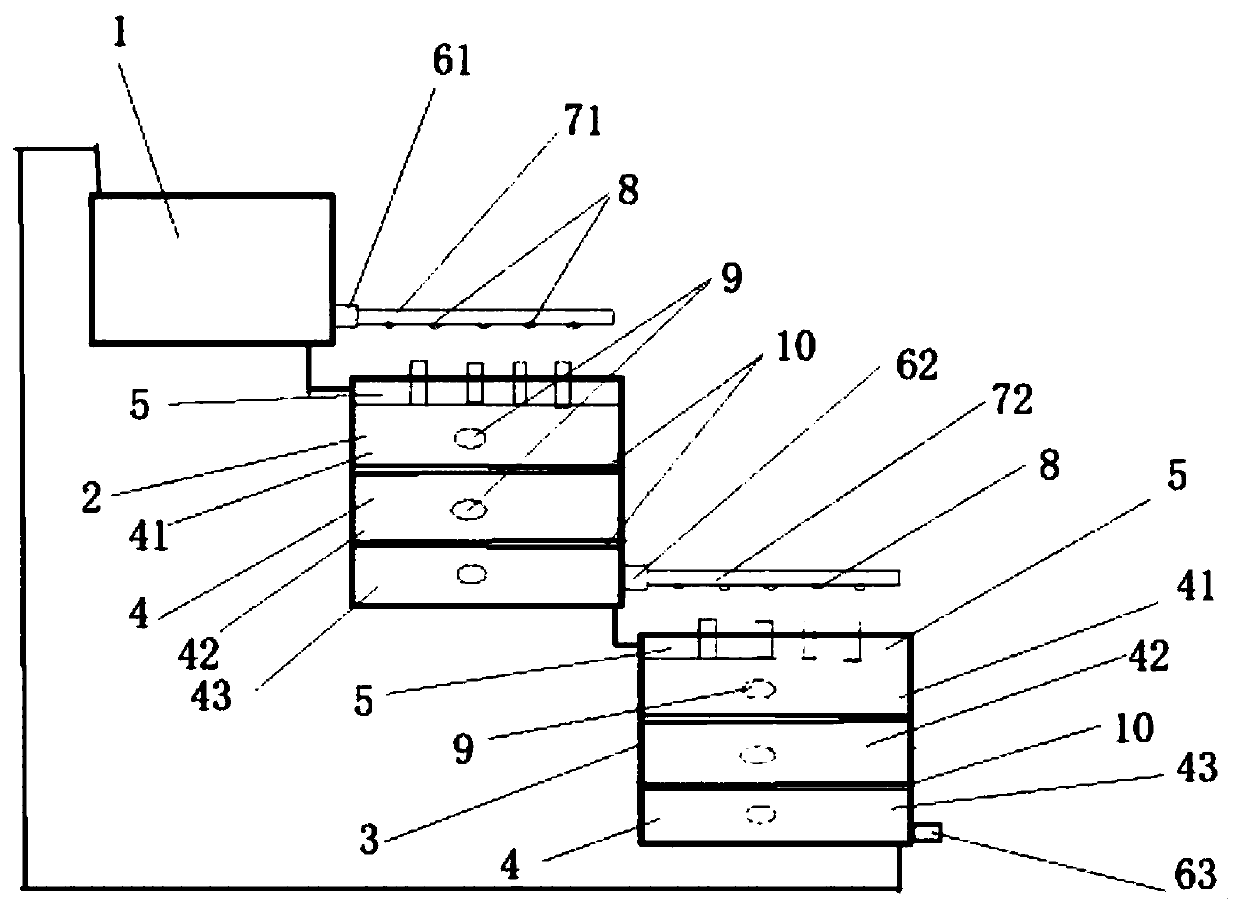

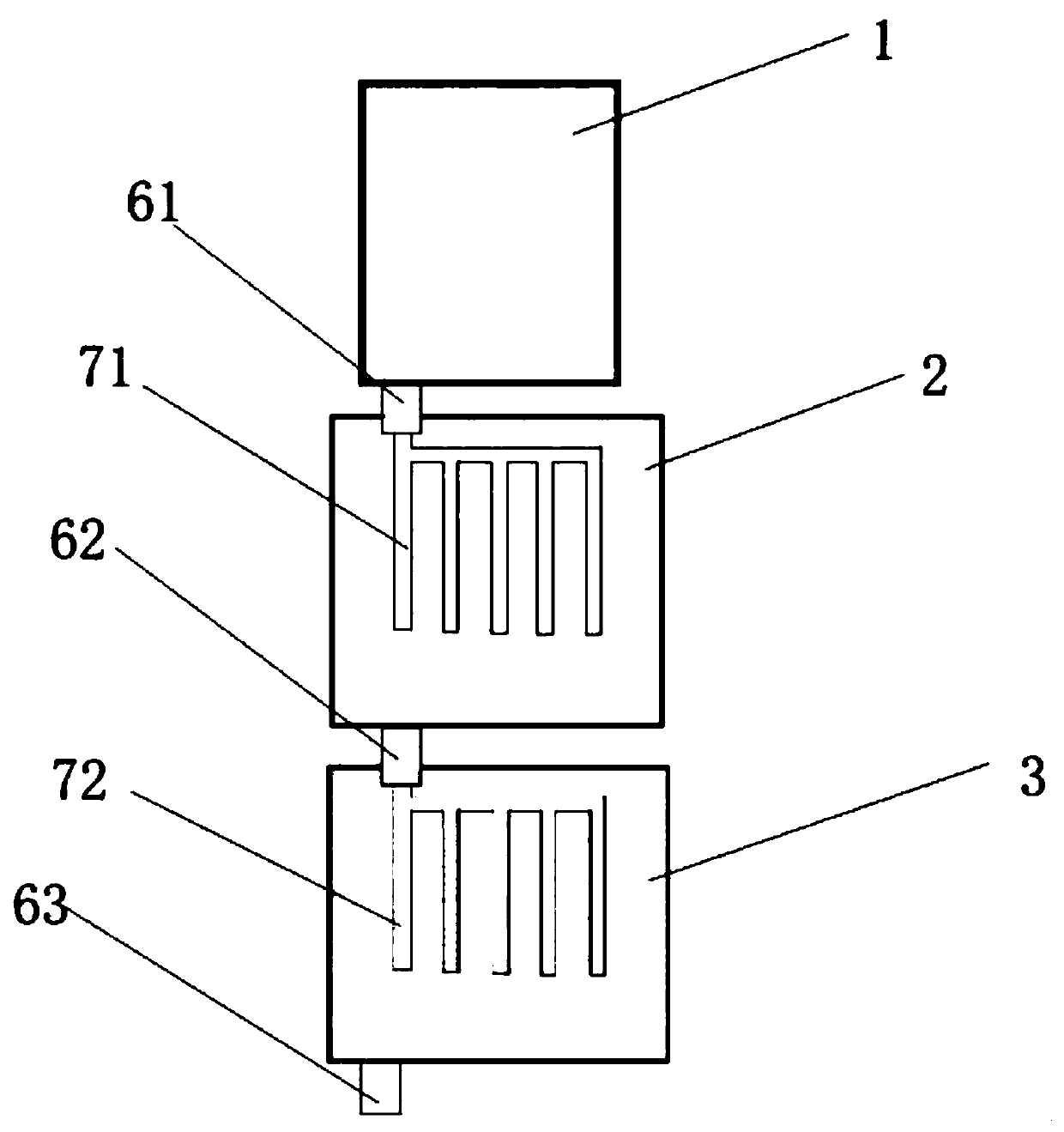

[0032]As shown in the figure, collect the sewage passing through the grid fence into the sedimentation tank 1, add 30 grams of microbial flocculant per ton of sewage, let it settle for 12 hours, and then transport the sewage to the diafiltration device for diafiltration purification; the diafiltration The device includes a primary diafiltration tank 2 and a secondary diafiltration tank 3, and the sedimentation tank 1, the primary diafiltration tank 2 and the secondary diafiltration tank 3 are arranged in steps; Filter the water layer 4 and the topsoil layer 5, and send the sewage from the water outlet 61 at the bottom of the sedimentation tank 1 into the first parallel pipeline 71 above the primary infiltration tank 2 near the sedimentation tank 1, and from the lower end of the first parallel pipeline 71 Multiple groups of water outlet holes 8 drip into the water hyacinth planted in the top soil layer 5 of the primary infiltration tank 2, and the sewage passes through the wetla...

Embodiment 2

[0038] As shown in the figure, collect the sewage passing through the grid fence into the sedimentation tank 1, add 25 grams of microbial flocculant per ton of sewage, let it settle for 17 hours, and then transport the sewage to the diafiltration device for diafiltration purification; the diafiltration The device includes a primary diafiltration tank 2 and a secondary diafiltration tank 3, and the sedimentation tank 1, the primary diafiltration tank 2 and the secondary diafiltration tank 3 are arranged in steps; Filter the water layer 4 and the topsoil layer 5, and send the sewage from the water outlet 61 at the bottom of the sedimentation tank 1 into the first parallel pipeline 71 above the primary infiltration tank 2 near the sedimentation tank 1, and from the lower end of the first parallel pipeline 71 Multiple groups of water outlet holes 8 drip into the water onion planted in the topsoil layer 5 of the primary infiltration tank 2, and the sewage passes through the wetland ...

Embodiment 3

[0044] As shown in the figure, collect the sewage passing through the grid fence into the sedimentation tank 1, add 20 grams of microbial flocculant per ton of sewage, let it settle for 21 hours, and then transport the sewage to the diafiltration device for diafiltration purification; the diafiltration The device includes a primary diafiltration tank 2 and a secondary diafiltration tank 3, and the sedimentation tank 1, the primary diafiltration tank 2 and the secondary diafiltration tank 3 are arranged in steps; Filter the water layer 4 and the topsoil layer 5, and send the sewage from the water outlet 61 at the bottom of the sedimentation tank 1 into the first parallel pipeline 71 above the primary infiltration tank 2 near the sedimentation tank 1, and from the lower end of the first parallel pipeline 71 Multiple groups of water outlet holes 8 drip into the water sunflowers planted in the topsoil layer 5 of the first-level infiltration tank 2, and the sewage passes through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com