A clean and dust-free feed processing plant

A processing plant and feed technology, which is applied in the field of clean and dust-free feed processing plants, can solve the problems of excessive dust in feed plants, achieve the effects of avoiding human harm, improving dust pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

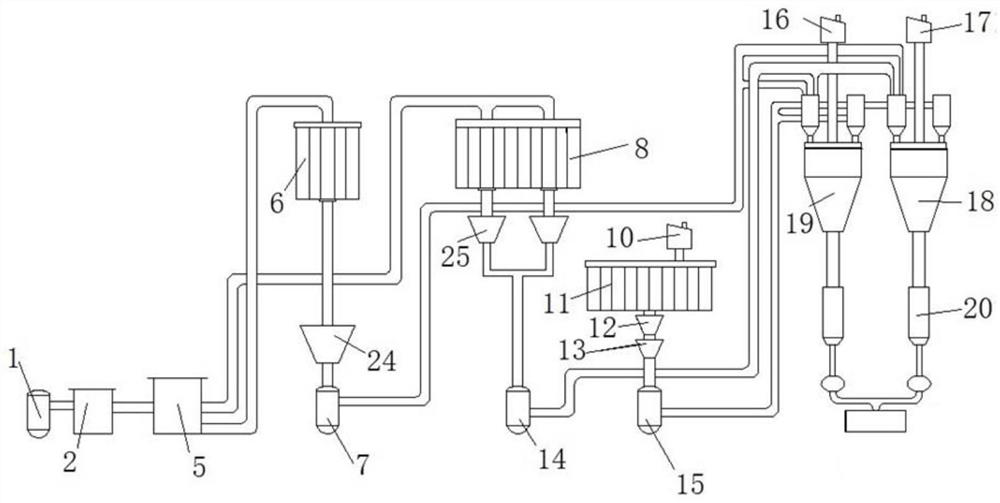

[0040] Example 1 Basic preparation of clean and dust-free feed processing plant

[0041] see Figure 1-3 , a clean and dust-free feed processing plant, consisting of a bulk raw material feeding port 2, a carrier feeding port 5, a carrier bin 6, a bulk raw material bin 8, a micro-dosage raw material feeding port 10, a micro-dosage raw material bin 11, and a receiving and packaging line , wherein one side below the bulk raw material feeding port 2 is connected to the air compressor 1, and the other side is connected to the bulk raw material warehouse 8 through a gas conveying pipeline; the lower side of the carrier feeding port 5 is connected to the carrier warehouse 6 through a mechanical conveying pipeline; The carrier warehouse 6 is a plurality of mutually independent warehouses arranged side by side, the top is sealed and connected to the mechanical delivery pipeline through their own independent pipelines; connected, a scale 24 is set in the middle of the vertical pipeline...

Embodiment 2

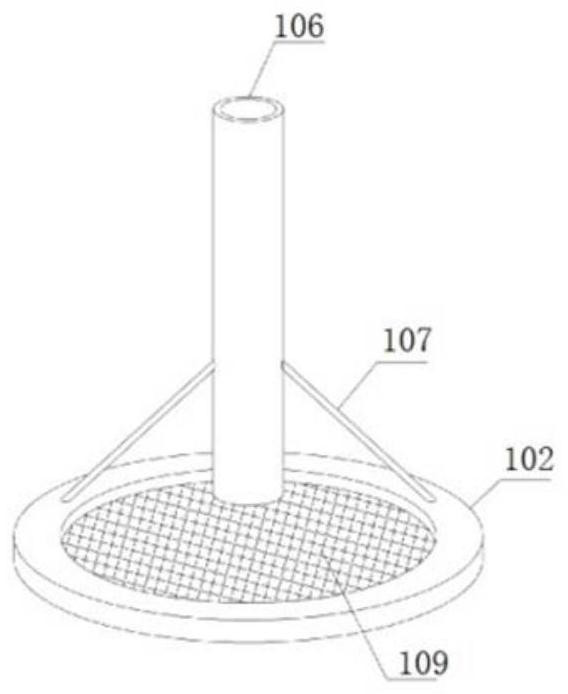

[0046] Example 2 A clean and dust-free feed processing plant using a ton bag feeding device

[0047] see Figure 4-7 , upgrade the configuration on the basis of the clean and dust-free feed processing plant in Example 1. Repeated operations at the feeding port of the carrier bin and the bulk raw material bin are prone to bag breakage and dust leakage, which is an important place for dust generation in the factory, but the existing feeding device is not enough to lift heavy raw material bags, and the raw material bags are in the incoming goods At the same time, the goods are purchased in large packages, many of which weigh up to one ton. If the original packaging can be lifted and fed, the dust generated during subcontracting and feeding can be greatly reduced.

[0048] The present invention designs a ton bag feeding device, and a ton bag feeding device is arranged beside the bulk raw material feeding port 2 and the carrier feeding port 5, and the ton bag feeding device includ...

Embodiment 3

[0052] Example 3 A clean and dust-free feed processing plant that adopts the automatic control sealing system of the dust collector

[0053] see Figure 8-10 , upgrade the configuration on the basis of the clean and dust-free feed processing plant in embodiment 2. Electromagnetic pulse dust collectors are generally installed on the top of bulk raw material warehouses, but after the existing electromagnetic pulse dust collectors have been used for a period of time, there will be a reset gap in the return spring inside the electromagnetic valve, and the seal is not tight, resulting in insufficient air pressure in the entire production line. When the work pressure is reached, the production line cannot start. At the same time, if the pulse solenoid valve is not tightly sealed, the continuous air supply will cause dust to overflow from the connection between the pulse solenoid valve and the dust collector, resulting in dust pollution. In the present invention, an automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com