Reclaimed tire grinding and sorting system

A sorting system and tire technology, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve problems such as inability to sort cleanly, low crushing efficiency, and low integrity of metal wires, so as to improve crushing efficiency and tires The effect of recycling rate and improving the efficiency of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

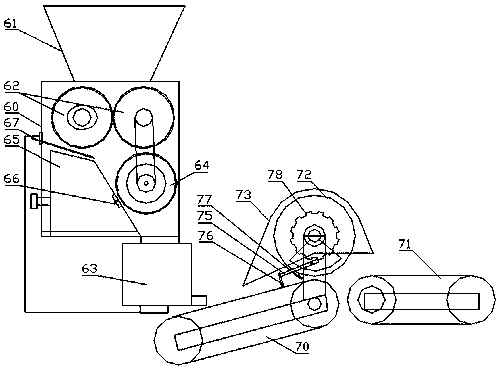

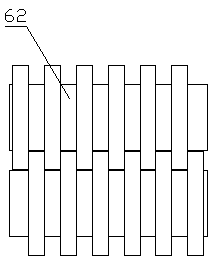

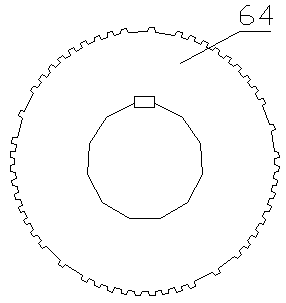

[0015] As shown in the accompanying drawings, the present invention includes a rubber block pulverizer and a magnetic separator. The rubber block pulverizer includes a body 60, a primary crushing device, a secondary crushing device and a vibrating screen 63, and the top of the body 60 has a first feeding port There is a second feed port on one side of the body 60, a discharge port on the bottom of the body 60, a lower hopper 61 is provided on the first feed port, and the primary crushing device includes two primary crushing rollers 62 and a crushing roller drive motor , the gear transmission between the two primary crushing rollers 62, the two primary crushing rollers 62 are installed in the body 60, and are located directly below the first feeding port of the body 60, the crushing roller driving motor is installed on the body 60, and One of the primary crushing rollers 62 is driven to rotate, and multiple groups of cutter heads are respectively arranged on the two primary crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com