Self-protection flux-cored wire capable of generating slag coating with special protection performance and preparing method

A technology of flux-cored welding wire and protective performance, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problem of one-time preparation and molding of metal structural parts without double-layer function, no slag beneficial coating, unfavorable fast operation, etc. problems, to achieve the effect of improving labor intensity, eliminating slag removal process, and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

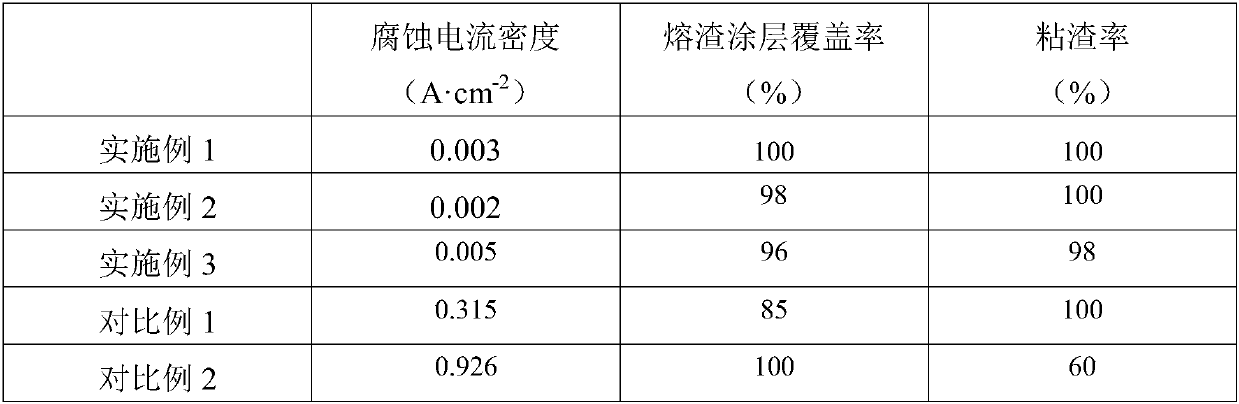

Embodiment 1

[0035]A self-shielding flux-cored welding wire that generates a slag coating with special protective properties, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: The core and the drug core are filled in the steel strip. The H08A composition of the steel strip is C 0.1%, Mn 0.3-0.55%, Si 0.3%, S≤0.03%, P≤0.03%. The drug core components are prepared according to the following quality: 60g of glass powder, 8g of zirconia powder, 0.05g of graphene powder, 6g of sodium potassium carbonate powder, 3g of potassium titanate powder, 5g of rutile powder, and 1g of corundum powder , 1g of sodium fluorosilicate powder, 15.95g of iron powder, the core powder accounts for 13% of the total weight of the welding wire. All powders were sieved through a 150-mesh sieve. Put the various powders taken into the powder mixer, mix for 30 minutes, and then add the mixed ...

Embodiment 2

[0037] A self-shielding flux-cored welding wire that generates a special protective slag coating, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the steel strip H08A is C: 0.1%, Mn: 0.3-0.55% , Si: 0.3%, S: ≤0.03%, P: ≤0.03%. The drug core components are prepared according to the following quality: 70g of glass powder, 2g of zirconia powder, 0.25g of graphene powder, 8g of sodium potassium carbonate powder, 2g of potassium titanate powder, 3g of rutile powder, and 5g of corundum powder , 2g of sodium fluorosilicate powder, 7.75g of iron powder, the core powder accounts for 25% of the total weight of the welding wire. All powders were sieved through a 150-mesh sieve. Put the various powders taken into the powder mixer, mix for 30 minutes, and then add the mixed powder into the U-shaped 0.9×14mm H08A carbon steel belt groove. Then close the U-shaped groove so that the powder is wrapped therein. Then make ...

Embodiment 3

[0039] A self-shielding flux-cored welding wire that generates a special protective slag coating, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the steel strip H08A is C: 0.1%, Mn: 0.3-0.55% , Si: 0.3%, S: ≤0.03%, P: ≤0.03%. The drug core components are prepared according to the following quality: 80g of glass powder, 3g of zirconia powder, 0.85g of graphene powder, 2g of sodium potassium carbonate powder, 1g of potassium titanate powder, 2g of rutile powder, and 3g of corundum powder , 3g of sodium fluorosilicate powder and 5.15g of iron powder, the core powder accounts for 18% of the total weight of the welding wire. All powders were sieved through a 150-mesh sieve. Put the various powders taken into the powder mixer, mix for 30 minutes, and then add the mixed powder into the U-shaped 0.8×12mm H08A carbon steel belt groove. Then close the U-shaped groove so that the powder is wrapped therein. Then le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com