A molding die for a hinge connecting part of a display bracket

A display bracket and shaft connection technology, which is applied in the field of forming molds for shaft joints, can solve problems that restrict the development and promotion of integrated shaft connections, increase labor costs, equipment supporting costs, and high production costs, etc., to achieve reduction The effect of labor cost, ensuring positioning, and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

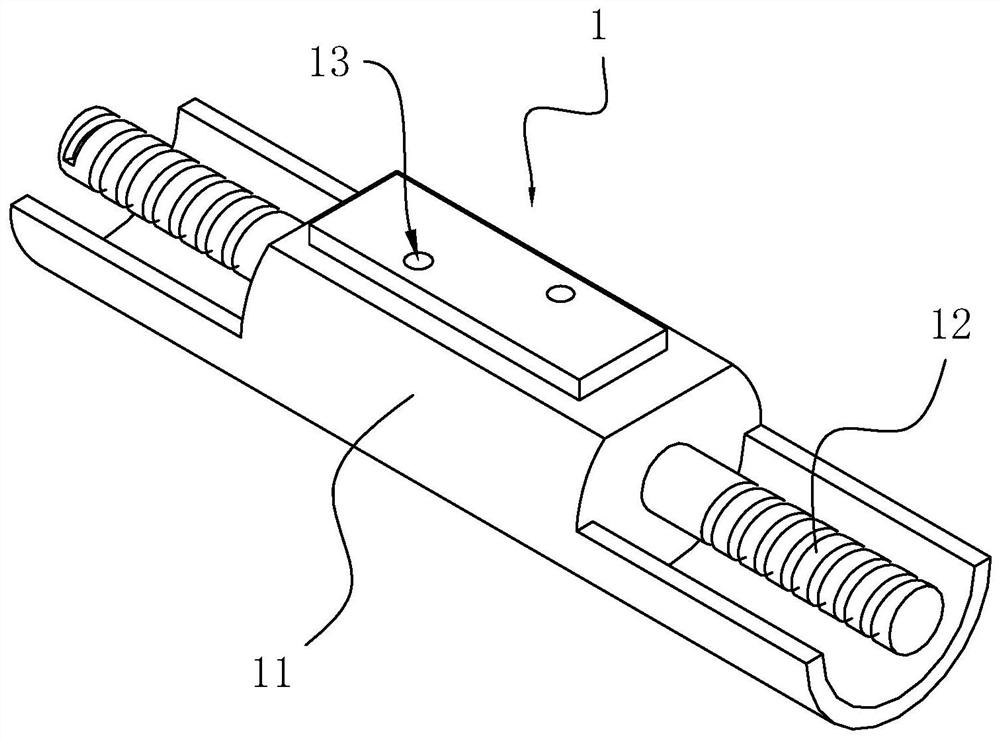

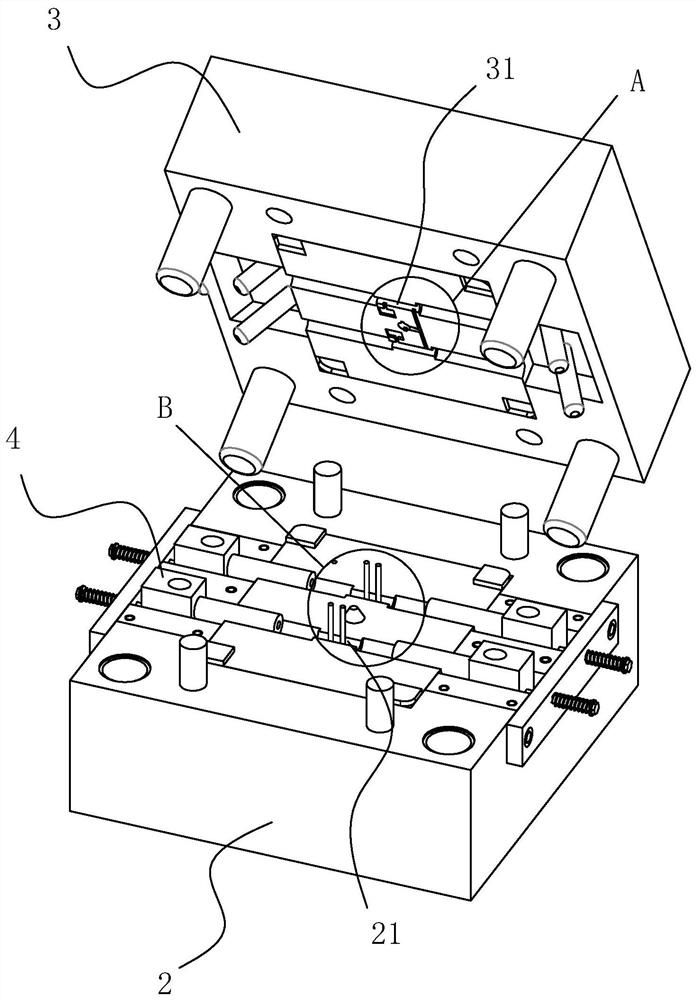

[0047] Embodiment 1: A forming mold for the hinge connecting piece of the display bracket, combined with figure 2 with image 3 As shown, it includes a left mold 2 and a right mold 3 and several sets of connecting shaft positioning components 4 arranged on the left mold 2 and arranged along the height direction of the left mold 2 for realizing the integral molding of the connecting shaft 12 and the body 11; On the side of the left mold 2 facing the right mold 3, there are several first grooves 21 arranged along the height direction of the left mold 2; The second grooves 31 arranged in the height direction, when the left mold 2 and the right mold 3 are merged, each first groove 21 cooperates with each second groove 31 to enclose and form several grooves for forming the body 11 cavity.

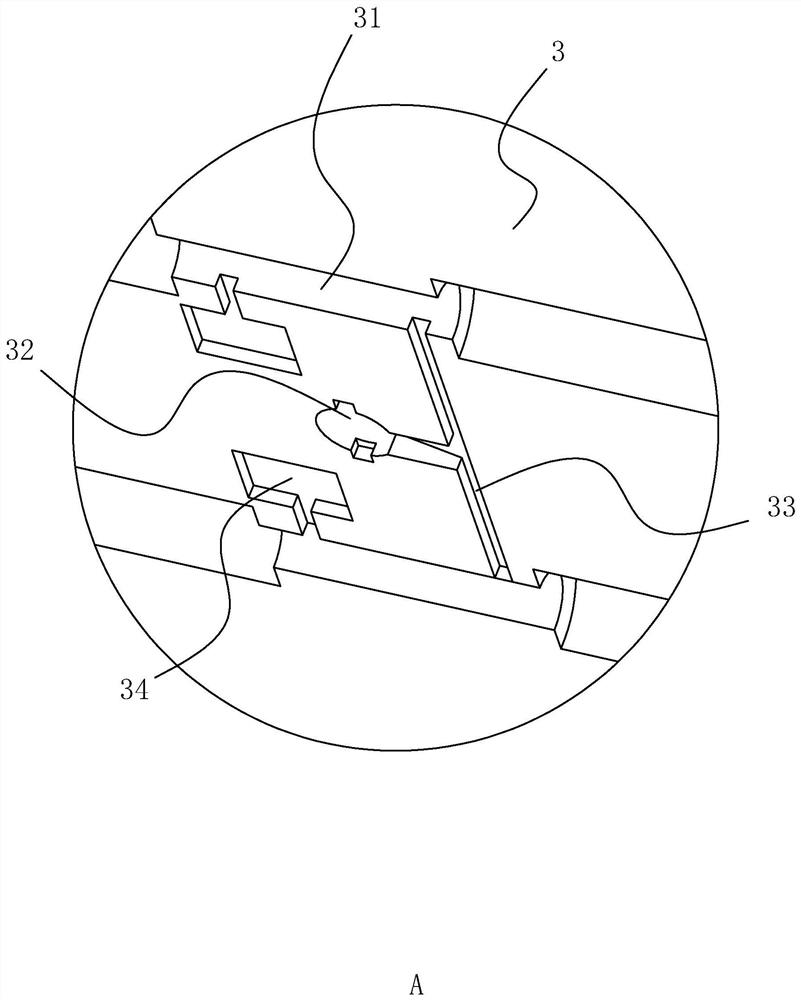

[0048] which, combined with image 3 As shown, the right mold 3 is provided with a runner 32 for injection of the molten metal solution into the molding die, and a runner 33 communicating wi...

Embodiment 2

[0059] Embodiment two: if Figure 11 As shown, the difference from Embodiment 1 is that each positioning member 41 is provided with an inclined guide surface 412, and the two ends of each inclined guide surface 412 are respectively connected to the side of the positioning member 41 away from the first groove 21. And the locating piece 41 is connected away from the side of the left mold 2, and the right mold 3 is provided with several wedge-shaped pieces 38 that are respectively matched with each piece of locating piece 41 in quantity and position. When the left mold 2 and the right mold 3 merged, each The wedge blocks 38 respectively abut against the inclined guide surfaces 412 for pushing the positioning member 41 to move toward the direction where the first groove 21 is located.

[0060] When the left mold 2 and the right mold 3 are separated, each piece of wedge block 38 will move away from the left mold 2. At this time, each piece of second elastic member 52 resets, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com