A hexagonal steel bar drawing machine tool

A hexagonal steel and machine tool technology, applied in the field of hexagonal steel bar drawing machine tools, can solve the problems of mold influence, waste of material, increase of production cost, etc., and achieve the effect of material property modification and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

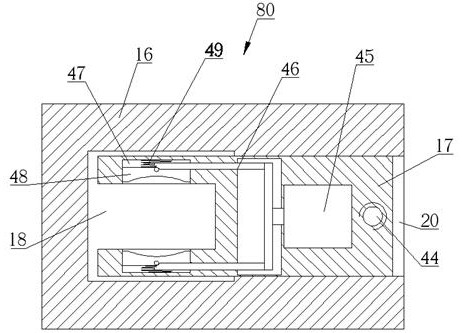

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

[0018] refer to Figure 1-5 , a hexagonal steel bar drawing machine tool according to an embodiment of the present invention, including a base 10 placed on the ground, a discharge table 11 is fixedly installed on the top surface of the base 10, and the right side of the discharge table 11 The transport seat 16 is fixedly installed on the side, and two first processing seats 21 are fixedly installed symmetrically on the left and right sides of the transport sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com