A method for preparing high-quality phosphorous concentrate

A phosphate concentrate, high-quality technology, applied in the direction of solid separation, flotation, etc., can solve the problems that the content of sesquioxide cannot be effectively reduced, the content of calcium sulfate dihydrate in phosphogypsum is reduced, and the production of wet-process phosphoric acid is affected. Achieve the effects of low SiO2, reduced emissions and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

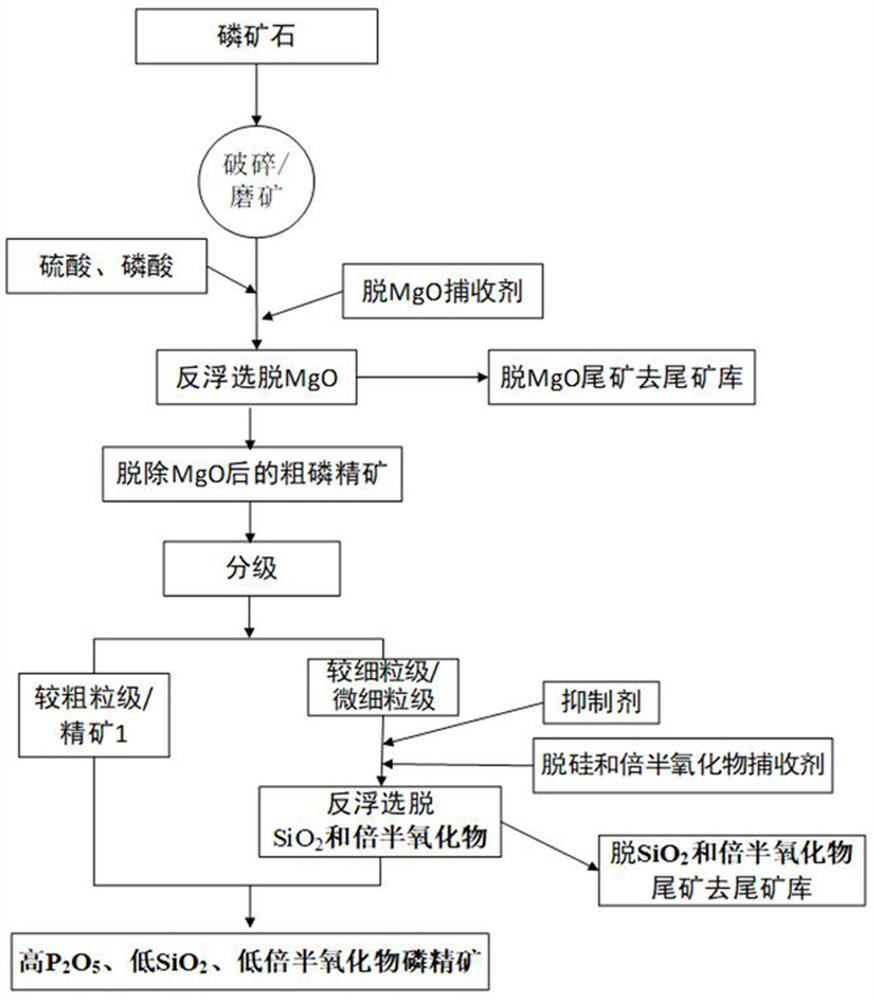

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention in conjunction with the following described in further detail, but not limited by these embodiments.

[0039] Processing of phosphate rock in this embodiment is the production of a large state-owned enterprises in my country with the beneficiation of phosphate rock mine:

[0040] The phosphate rock P 2 O 5 : 20.15%, MgO: 4.97%, SiO 2: 16.13%, double half oxide: 3.06%. The ore milling is from -200 mesh> 92%, which makes the monomer dissolution> 85%, and the adjustment of the slurry flotation concentration is 25%, and 10 ㎏ / t, phosphoric acid is added to the weight of the flotation mineral pulp. 1㎏ / t, pH value is 4.5, and the magnesia receptant 2.6 ㎏ / t for anti-flometry removal MgO, the magnesia is sodium oleate, stearic acid, ether amine according to 1: 0.5: 0.1 The proportion is mixed.

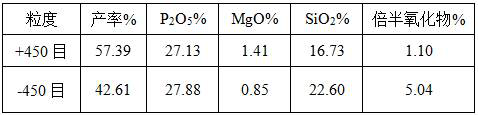

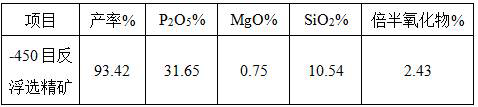

[0041] The magnesia crude phosphorus concentrate index obtained after the MgO anti-floating selection is P 2 O 5 : 27.45%, MGO: 1.17%, SIO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com