Method for treating oil-in-water emulsion by using positive electricity enhanced oleophilic and hydrophobic three-dimensional porous material

A lipophilic, hydrophobic, three-dimensional porous technology, applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve problems such as poor infiltration and limited contact probability, and achieve enhanced oil-water separation effect and high enrichment rate. , The effect of reducing effluent oil concentration and COD value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

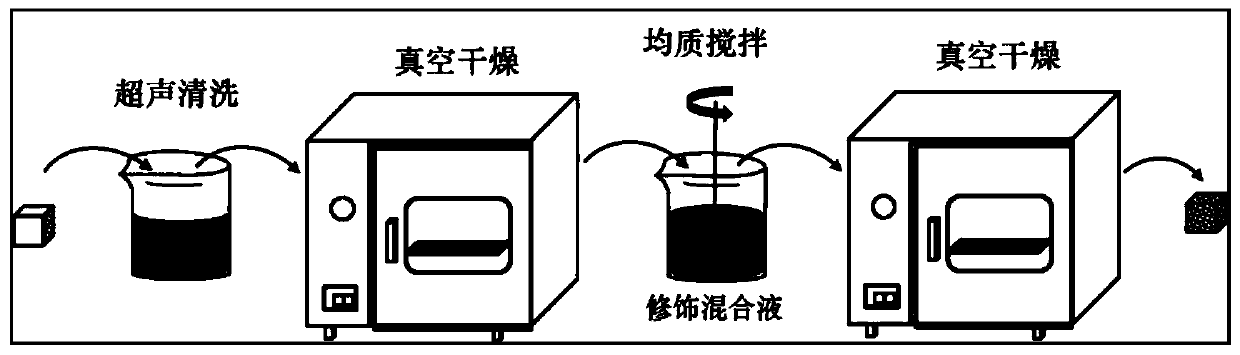

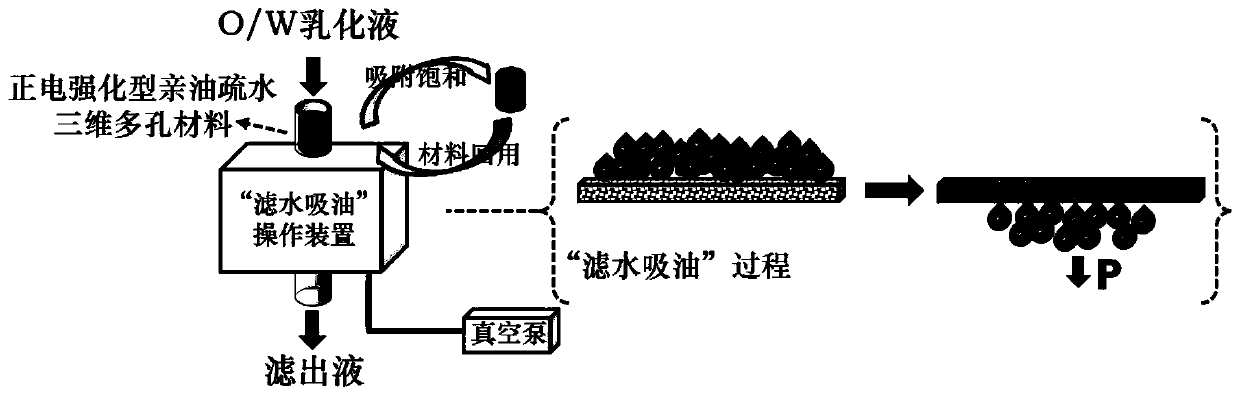

[0050] see figure 1 - attached Figure 5 , a method for treating oil-in-water emulsions with a positively charged lipophilic and hydrophobic three-dimensional porous material provided by the present invention and a comparison of the charging effect of the three-dimensional porous material: the volume is 1*1*3cm 3 , a melamine sponge (MS) with a pore size of 160 μm was soaked in an ethanol solution and ultrasonically cleaned for 20 minutes, washed with water, and dried in vacuum at 60° C. for 4 hours to a constant weight to obtain a pretreated melamine sponge; respectively weighed 0.4 g of dopamine (PDA), Dissolve 0.5g polyethyleneimine (PEI) in 200mL Tris-HCl buffer solution with a pH of 8.5, ultrasonically disperse for 5 minutes, and make a mixed modification solution; add the pretreated MS to the mixed modification solution, and mechanically stir at 200rpm After 18 hours, washed with water, dried in vacuum at 60°C for 4 hours, until constant weight, to obtain a positively-s...

Embodiment 2

[0053] Adopt the MSA prepared by Example 1 and the non-emulsifier oil-in-water emulsion prepared by the MS treatment (a) method of surface modification treatment in the treatment method provided by the invention, and compare the COD value and oil concentration of the filtrate to reduce Effect. The specific treatment method is as follows: Fill the MSA synthesized in Example 1 into the water filtration and oil pumping device, compress and reduce to 1 / 3 of the original volume before use. Prepare the oil-in-water emulsion prepared by the method (a), measure and record the COD value and oil concentration of the initial emulsion. Filter the emulsified hydraulic pressure through the material in a low negative pressure driving environment of 0kPa and a pressure of -1kPa, use a beaker or a plastic graduated tube to connect 10mL of the filtrate, and measure the COD value and oil concentration of the filtrate. Use 1*1*3cm 3 Melamine sponge (MS) replaced MSA, repeated the above operatio...

Embodiment 3

[0056] Prepare positively charged three-dimensional porous materials with different PEI application amounts of 0g to 0.7g, measure their surface chargeability, and use different PEI-modified porous materials to treat the emulsions stabilized by different chargeable emulsifiers prepared by the method (b), Compare its oil concentration reduction effect.

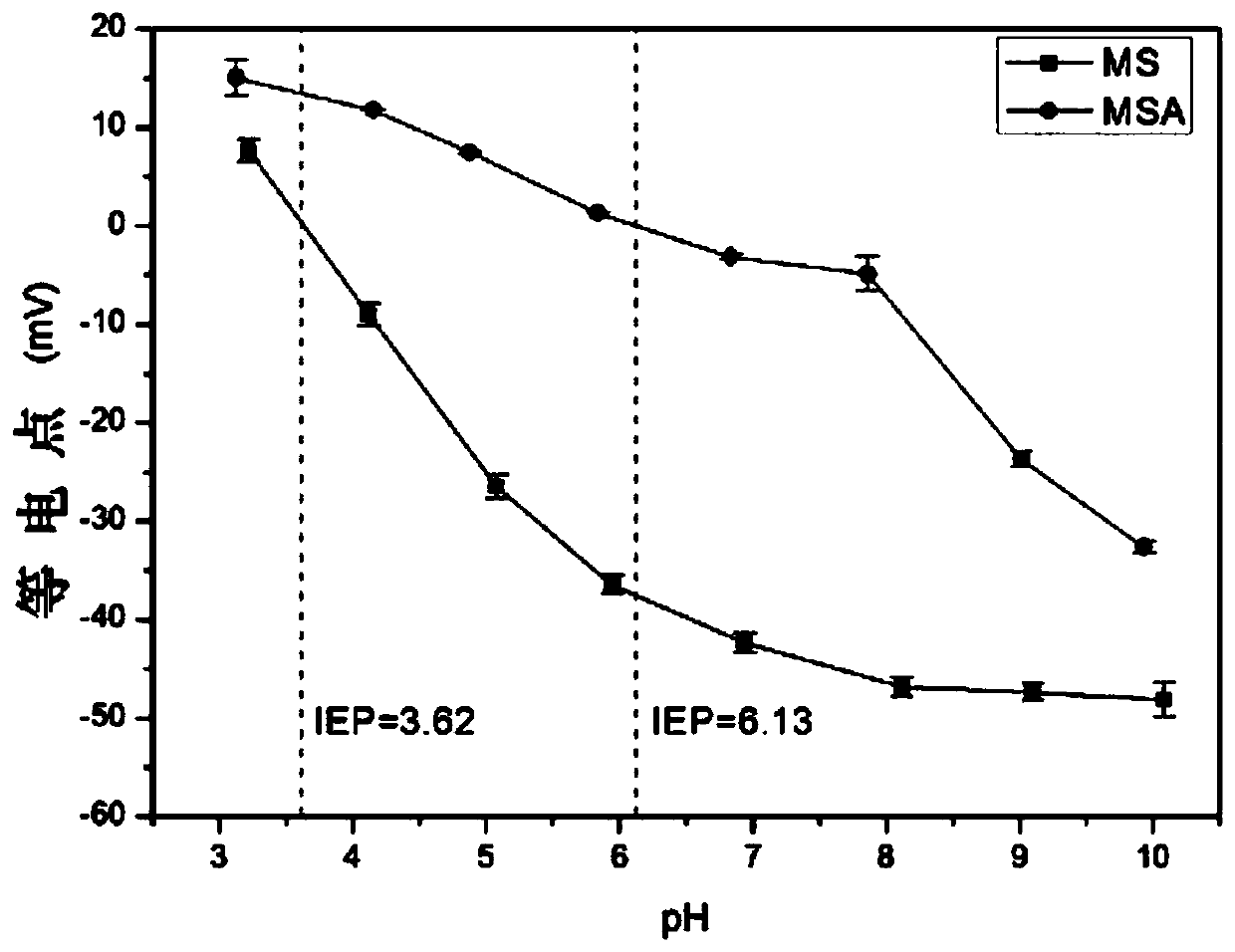

[0057] The specific operation method is as follows: The difference between the positively electrically strengthened three-dimensional porous material prepared in this example and the MSA prepared in Example 1 is that the quality of PEI added is different, which are 0g, 0.1g, 0.2g, 0.3g, 0.4 The gradients of g, 0.5g, 0.6g, and 0.7g prepared porous materials with different positive electric strengths, and characterized their chargeability. The results are as follows Figure 7 As shown, as the amount of PEI modification increases, the isoelectric point of the Zeta potential on the surface of the material moves positively; when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com