Special cable resistant to 1600 DEG C ultra-high temperature and flame scouring, and preparation method thereof

A special cable, ultra-high temperature technology, applied in the direction of cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of inability to bend, inconvenient installation and use, unstable electrical performance, etc., to achieve good bending performance and convenience The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

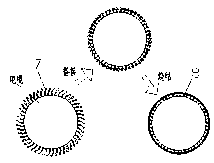

[0033] refer to figure 1, 1600℃ ultra-high temperature and flame-resistant special cable, from inside to outside, it includes conductor core 1, polyimide composite insulation layer 2 wrapped around conductor core 1, and polyimide composite insulation layer 2 extruded The outer silicone rubber inner layer 3, the airgel felt layer 4 wound outside the silicone rubber inner layer 3, the threaded pipe 5 tightly sleeved outside the airgel felt layer 4, and the silicone rubber outer layer extruded outside the threaded pipe 5 Layer 6 is characterized in that L-shaped supports 7 are annularly distributed on the outer ring of the silicone rubber outer layer 6, and all L-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com