Large-size angle steel high-frequency heating single-face bending machine used for extra-high voltage iron tower

A high-frequency heating and large-scale technology is applied in the field of large-scale angle steel high-frequency heating single-sided bending machines for UHV iron towers. It can solve the problems of high bending defect rate of workpieces, heat loss of workpieces, and burns of workers. Improve production efficiency, reduce area, and ensure the effect of bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

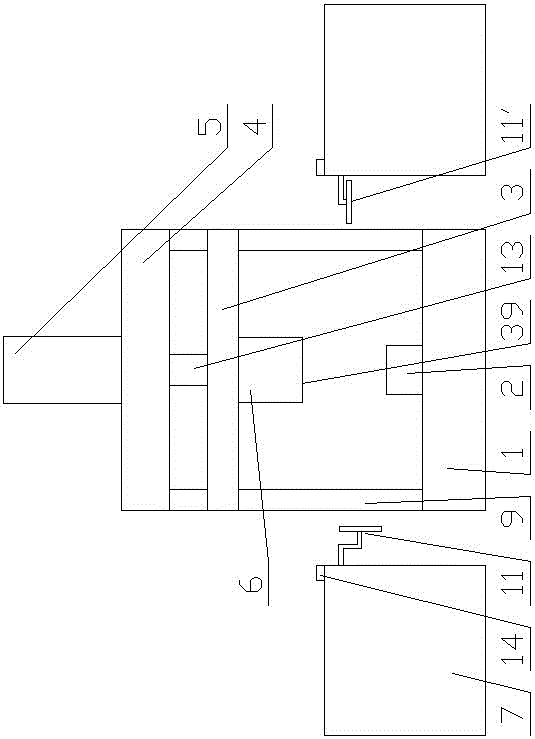

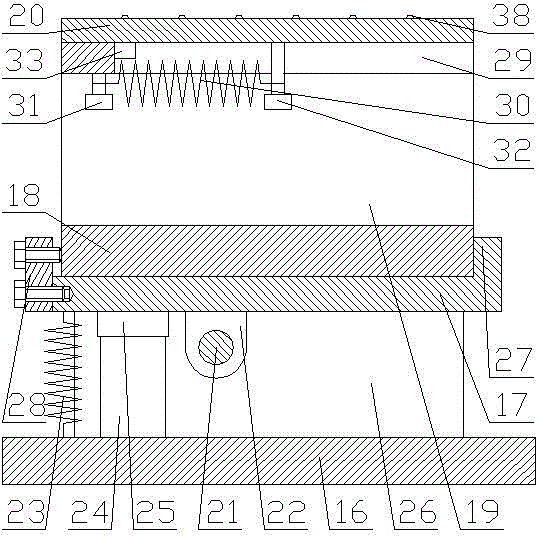

[0054] to combine Figure 1~Figure 4 As shown, the present invention includes a base 1, the front and rear ends of the top surface of the base 1 are symmetrically fixed with a workpiece placement frame 2, and the top of the workpiece placement frame 2 is movably connected with a briquetting block 3 up and down, and the bottom surface of the briquetting block 3 A bending die 6 is fixed, and the bending die 6 is located between the workpiece placement frames 2. The pressing block 3 provides a driving force through the piston A, and the piston A is fixed on the top plate 4, and the top plate 4 passes through the column 9 is fixed to the base 1; the left and right sides of the base 1 are respectively provided with a high-frequency heating machine 7, and the heating coil of the high-frequency heating machine 7 is parallel to the bending deformation surface of the workpiece, and the heating coil is surrounded by a The shape of the workpiece is the same as the shape of the bending de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com