Control method of titanium alloy compressor tip clearance

A technology of blade tip clearance and control method, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as burning out aircraft equipment, aircraft crashes, etc., to reduce gas leakage rate, improve efficiency, and coating thickness distribution. low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

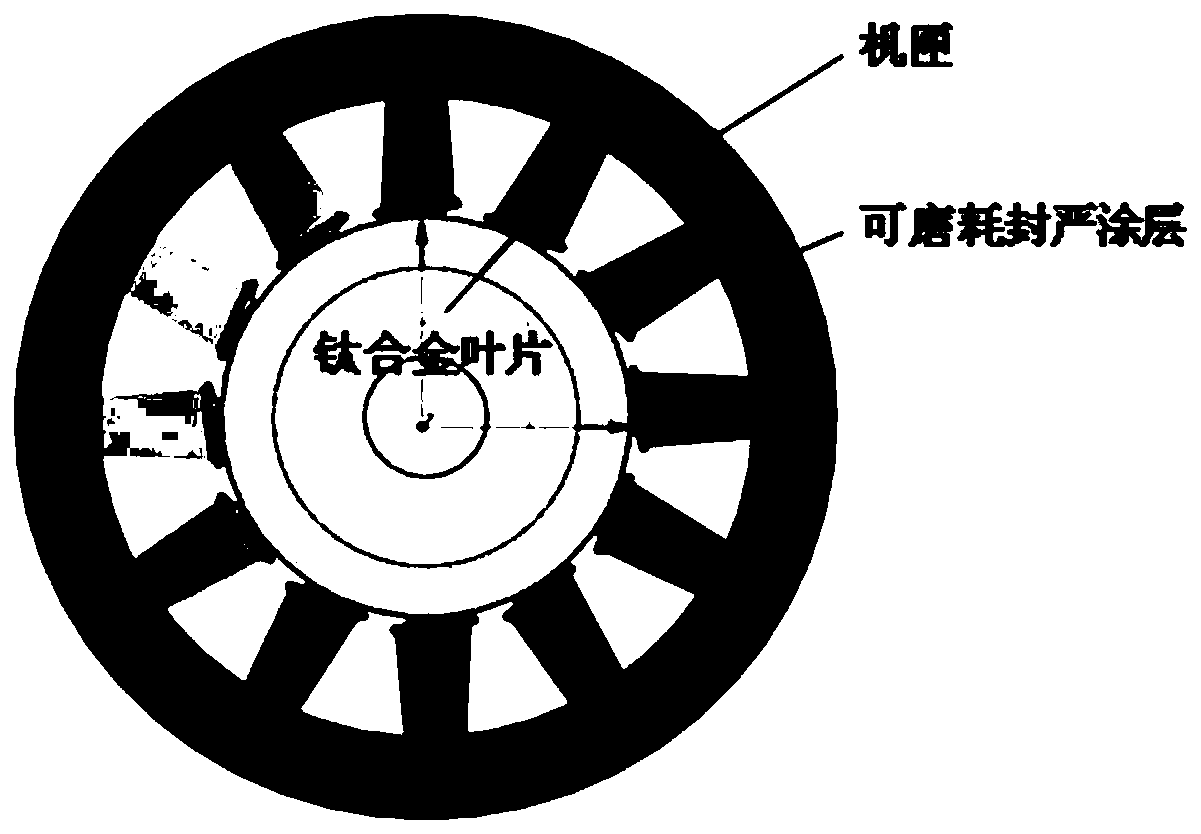

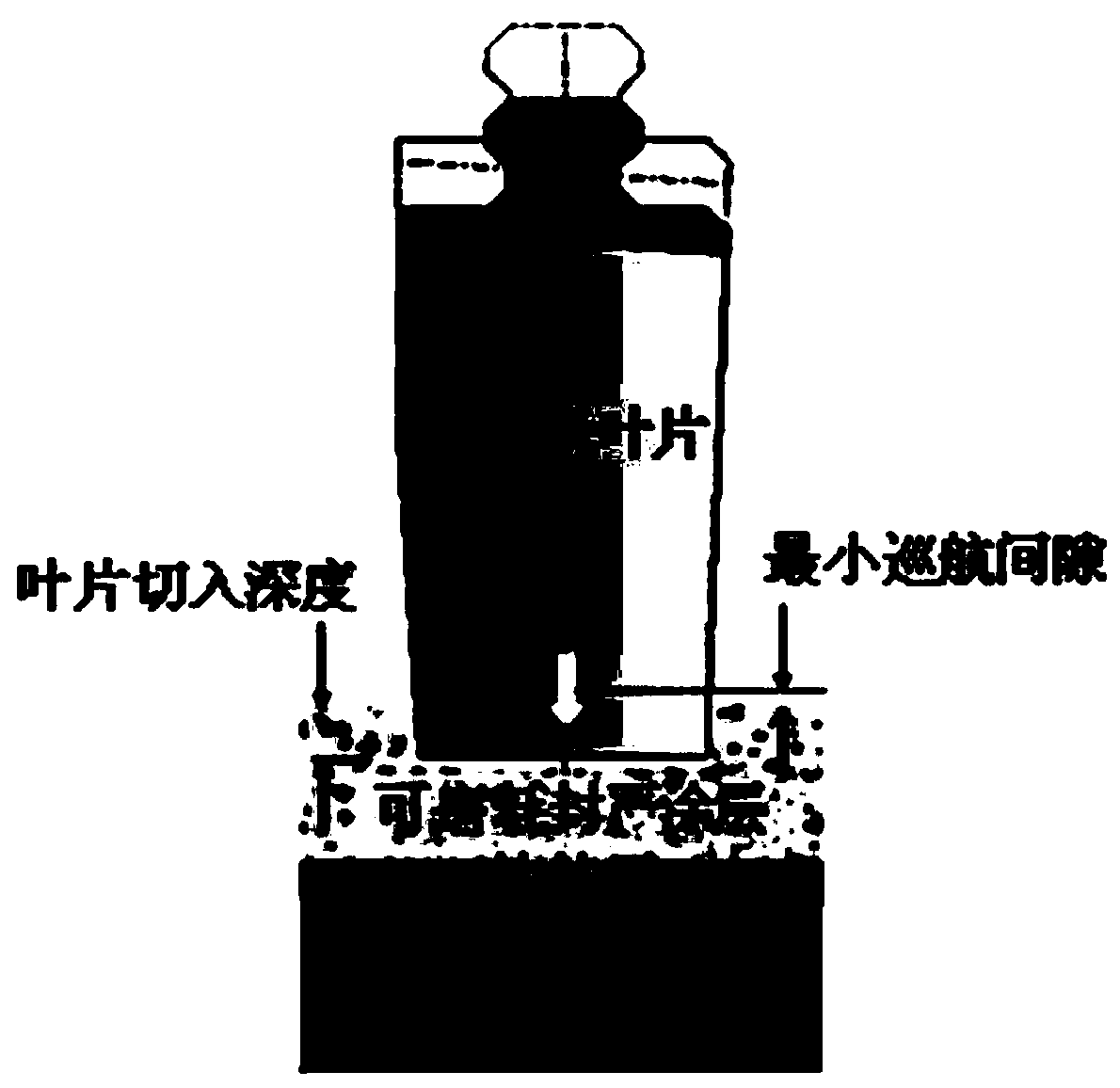

[0026] Such as figure 1 , 2 As shown, the abradable sealing coating NiCrFeAl-BN is prepared by plasma spraying method on the inner wall of the casing, and the specific preparation process is as follows:

[0027] 1) Parts cleaning: Use absorbent cotton or a brush dipped in acetone to carefully wipe and clean the sprayed area and adjacent areas of the parts to completely remove the oil on the surface of the parts.

[0028] 2) Protection: Use protective tooling and high-temperature protective tape to shield and protect the non-sprayed areas of the parts. After the protection is completed, a second confirmation is required to ensure that there is no leakage or over-protection.

[0029] 3) Sand blowing: put the parts into the sand blowing machine, and ensure that the clamping position of the parts is correct and firm. After stabilization, perform sand blowing on the spraying area; after the sand blowing is completed, use compressed air to blow off the floating dust on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com