Grader automatic control system

An automatic control system and grader technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovelers, construction, etc., can solve the problem of low construction accuracy, inability to intuitively understand the leveling status information, Consumption of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

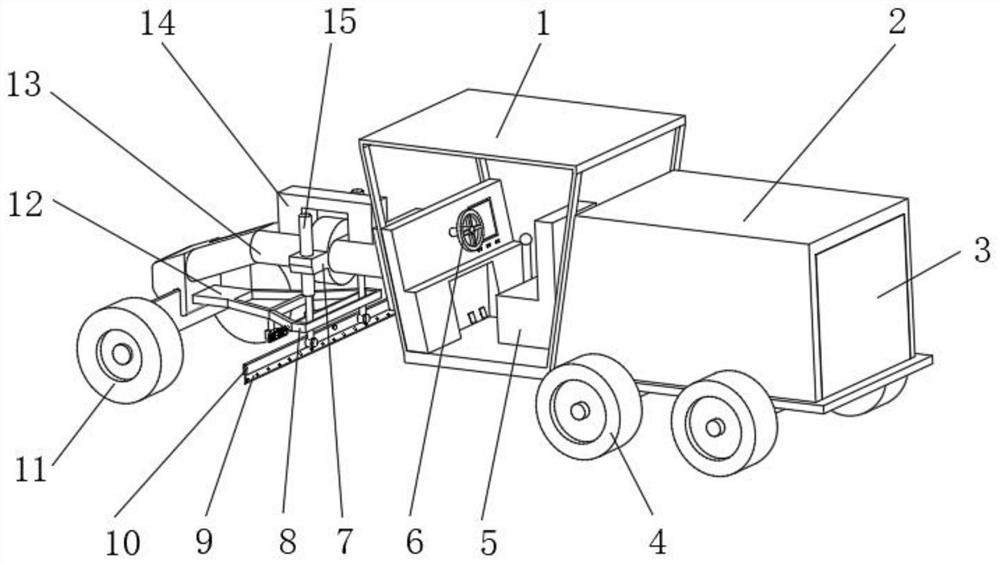

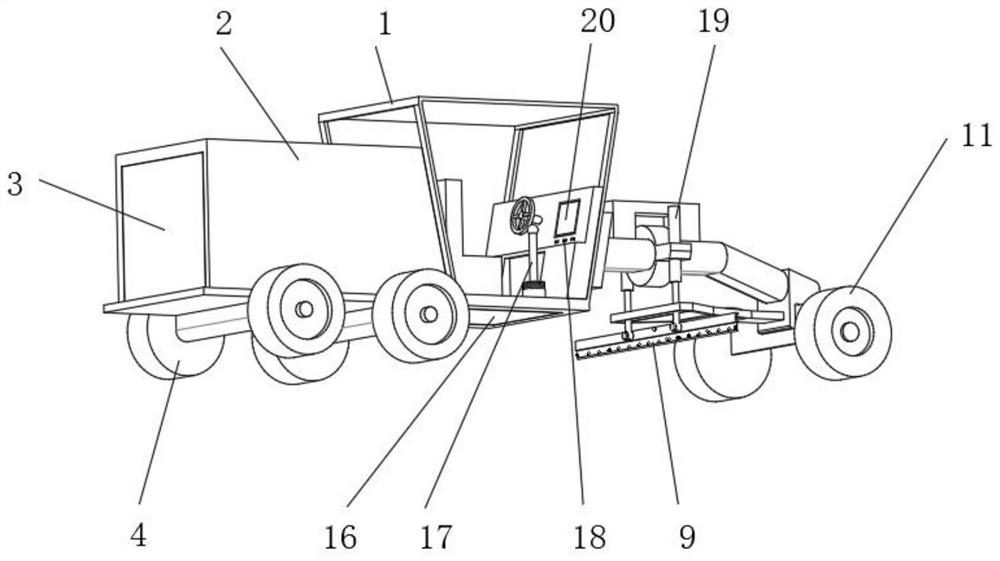

[0033] An automatic control system for a grader, such as Figure 1-6 As shown, the main body 1 is included. The outer wall of the main body 1 is welded with a control room 2; the control room 2 is provided with a GNSS directional antenna, a GNSS positioning antenna and a ZDT820 positioning and directional terminal device; and the outer wall of the control room 2 passes The lock body is connected with the control room door 3; the inner wall of the main body 1 is fixed with a console by bolts; the outer wall of the console is installed with an operation screen 20 through a mounting seat; and the outer wall of the console is fixed with a USB Interface 18, the user can import the preset design model through the USB interface 18, and transmit the data to the control unit in the control room 2, so that the motor grader can automatically adjust the upper and lower positions of the scraper according to the height of the designed different positions; the main body 1 One side outer wall ...

Embodiment 2

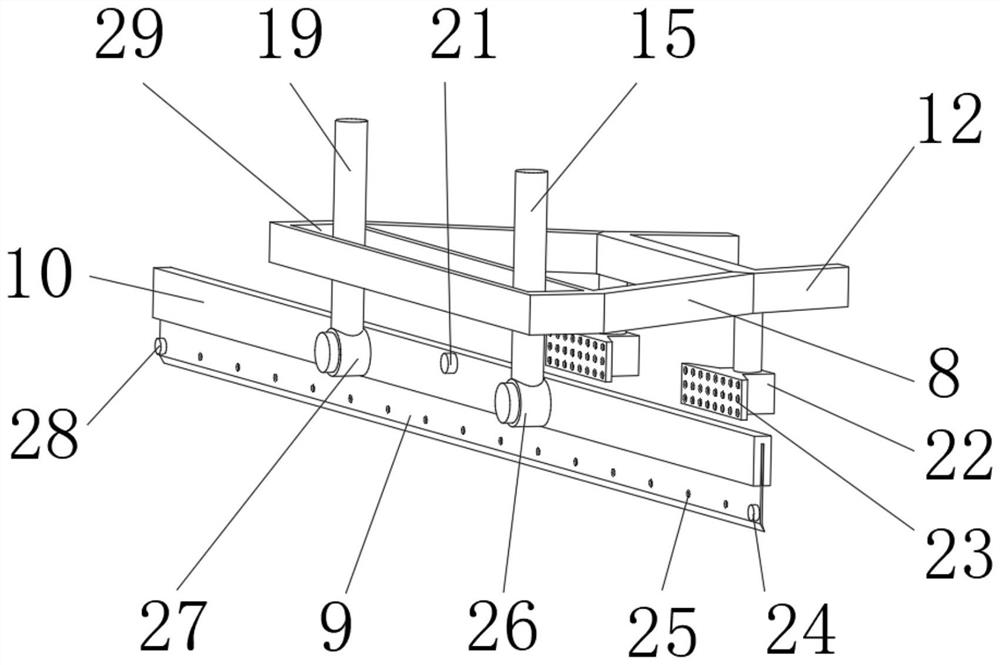

[0042] An automatic control system for a grader, such as figure 1 As shown, in order to further ensure operation safety; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the front car body 13 is welded with a connecting frame 12, and the outer wall of the connecting frame 12 is welded with a limit frame 8. A limit slot 29 is provided on the outer wall of the top of the limit frame 8; by setting the limit slot 29, the movable range of the scraper 9 can be further restricted, which ensures the safety of the operation.

[0043] When this embodiment is in use, because one end of the first hydraulic cylinder 15 and the second hydraulic cylinder 19 passes through the limiting groove 29, the scraper 9 is connected via a rotating seat and other mechanisms. If the first hydraulic cylinder 15 and the second hydraulic cylinder 19 are telescopic If the fit exceeds the safe position, or the rotation range of the rotating body 7 is too large, the ...

Embodiment 3

[0045] An automatic control system for a grader, such as figure 1 , image 3 As shown, in order to improve the operating efficiency of the scraper 9; this embodiment makes the following improvements on the basis of embodiment 1: the bottom outer wall of the connecting frame 12 is welded with a spray head 22, a water tank and a pressure pump are arranged inside the control room 2, and the spray head 22 passes The internal water pipe is connected with the water tank, the spray head 22 and the pressure pump are controlled by the control unit, and the outer wall of the spray head 22 is provided with evenly distributed spray holes 23; by setting the spray head 22, the scraper 9 can be cleaned by controlling the spray head 22 to spray water, thereby Improve operational fluency and increase operational efficiency.

[0046] In order to increase the scope and cleaning effect; such as image 3 As shown, the spray head 22 has a horn-shaped structure. By setting the spray head 22 in a horn-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com