Preparation method of super-weather-resistant titanium dioxide

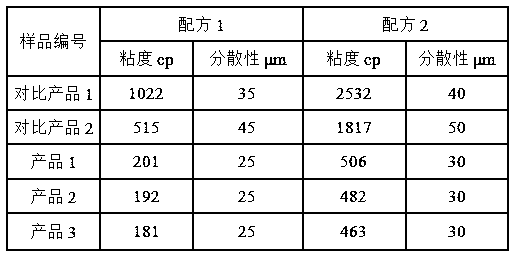

A titanium dioxide and super-weather-resistant technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve problems such as high oil absorption and water absorption, poor storage stability of paint, low oil absorption or water absorption, etc. Achieve the effects of reduced oil absorption and water absorption, good storage stability, and good formula applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the qualified chlorination base material, beat the slurry and dilute it to 280g / L, heat to 95℃, adjust the pH to 10.0 with sodium hydroxide solution; add 2.5wt% sodium silicate solution (with SiO 2 Calculate), add time 20min; adjust the pH of the slurry with dilute sulfuric acid to 6.0, adjust the time to 150min, after homogenizing for 30min, add 2.0wt% aluminum sulfate solution (with Al 2 O 3 Calculate), while adding sodium hydroxide solution to keep the slurry pH at 7.0 unchanged, adding time for 30 minutes, homogenizing for 30 minutes and then sanding, the sanding particle size is controlled to 0.32μm; the hydrothermal reaction is carried out at 240 ℃, the reaction The time is 3h; after cooling to 50°C, water washing (water washing conductivity 2 The total amount of TMP is 0.3wt%, and the vapor-solid ratio is 1.8.

Embodiment 2

[0033] Take the qualified chlorination method base material, beat the slurry and dilute it to 240g / L, heat it up to 80℃, adjust the pH to 11.0 with sodium hydroxide solution; add 2.0wt% sodium silicate solution (with SiO 2 Calculate), adding time 20min; adjust the pH of the slurry with dilute sulfuric acid to 6.0, adjusting time to 150min, after homogenizing for 30min, add 2.5wt% aluminum sulfate solution (with Al 2 O 3 At the same time, add sodium hydroxide solution to keep the pH of the slurry unchanged at 7.0. Add time for 30 minutes, homogenize for 30 minutes, and then sand mill. The sand mill particle size is controlled to 0.31 μm; the hydrothermal reaction is carried out at 200 ℃. The time is 5h; after cooling to 50°C, water washing (water washing conductivity 2 The total amount of TMP is 0.3wt%, and the vapor-solid ratio is 1.8.

Embodiment 3

[0035] Take the qualified chlorination base material, beat the slurry and dilute it to 200g / L, heat to 75℃, adjust the pH to 7.0 with sodium hydroxide solution; add 1.5wt% zirconium oxychloride solution (with ZrO 2 Calculate), add time 20min; adjust the pH of the slurry with sodium hydroxide solution to 8.5, adjust the time for 60min, after 30min homogenization, add 3.0wt% aluminum sulfate solution (with Al 2 O 3 At the same time, add sodium hydroxide solution to keep the pH of the slurry unchanged at 7.0. Add time for 30 minutes, homogenize for 30 minutes and then sand mill. The particle size of sand mill is controlled to 0.30 μm; the hydrothermal reaction is carried out at 120°C. The time is 8h; after cooling to 50°C, water washing (water washing conductivity 2 The total amount of TMP is 0.3wt%, and the vapor-solid ratio is 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com