Preparation method of polyvinylidene fluoride composite mixture, and polyvinylidene fluoride composite membrane and preparation method and application thereof

A polyvinylidene fluoride and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of materials that cannot resist pollution and poor membrane formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

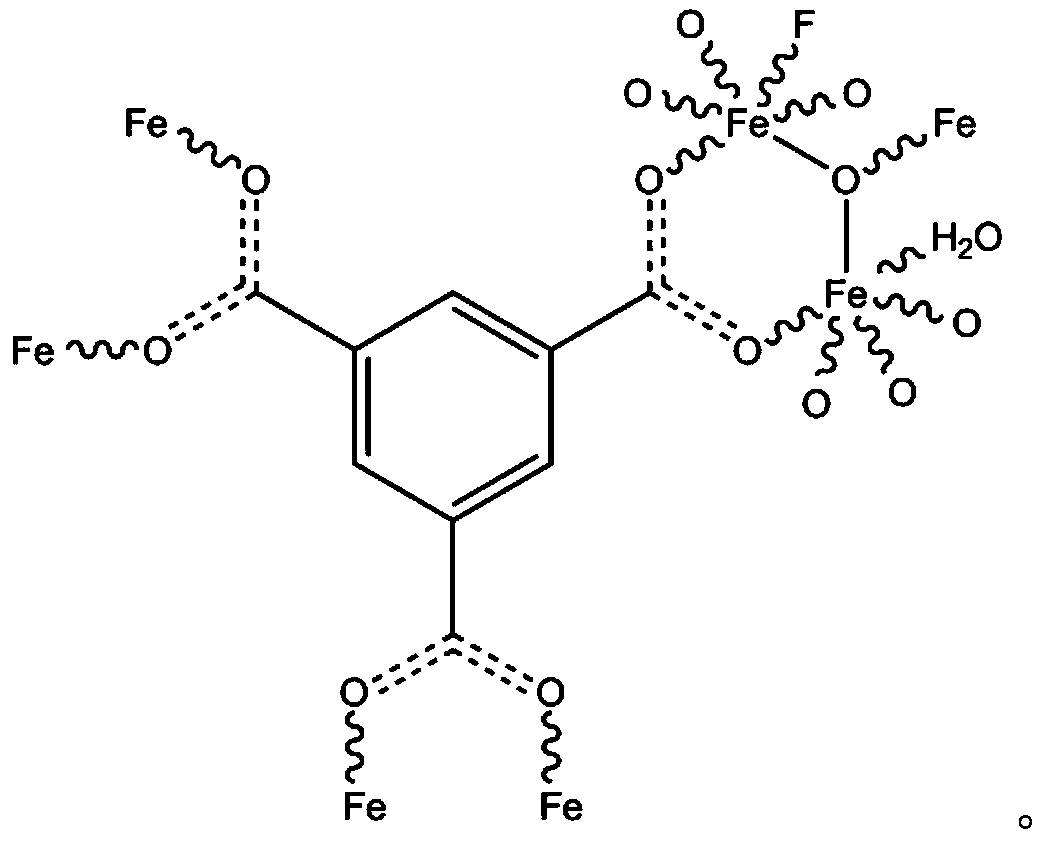

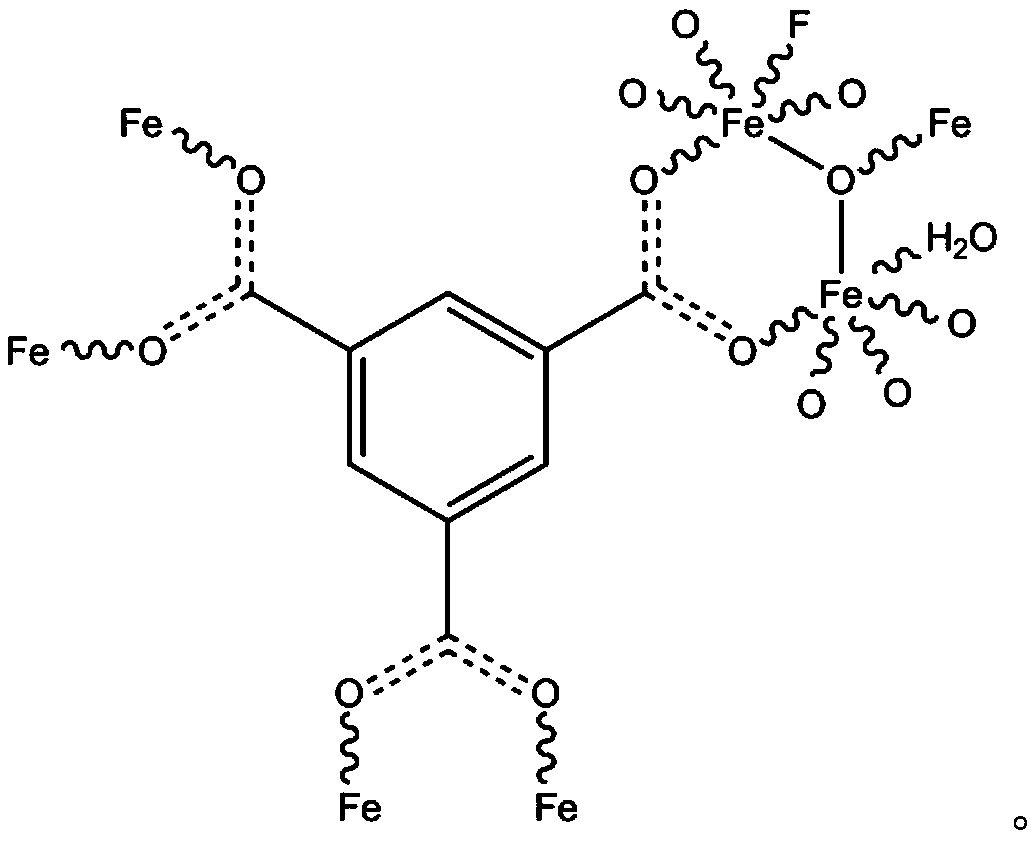

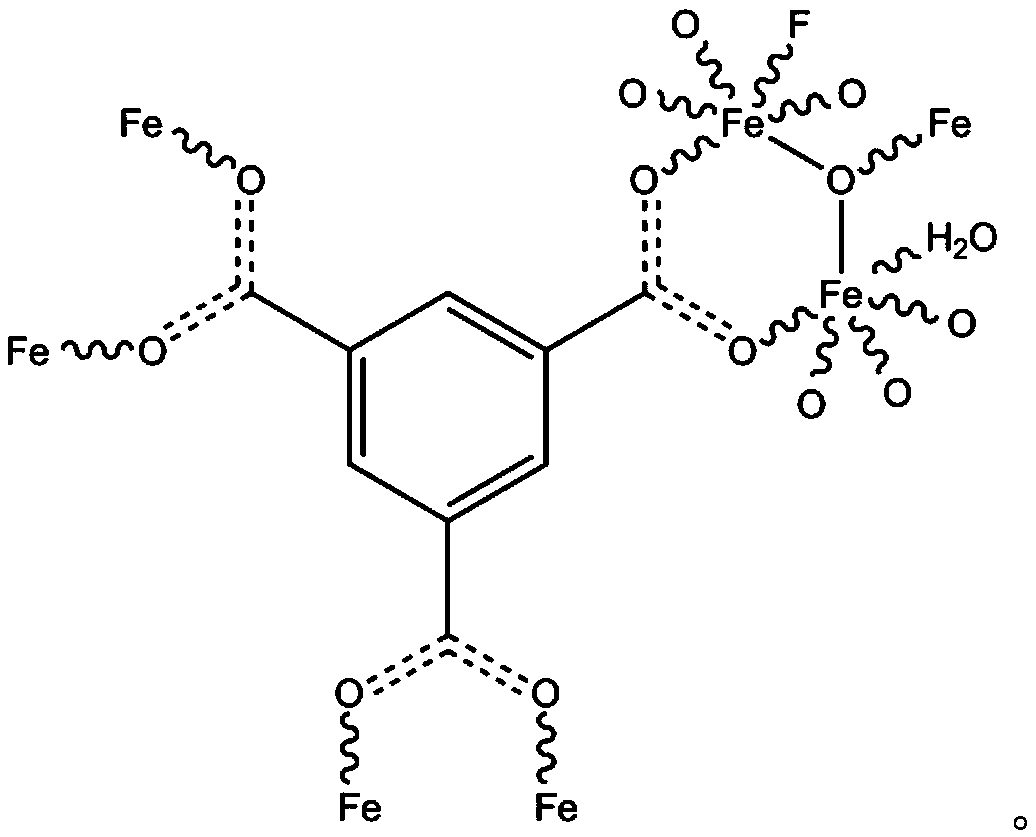

[0045] (1) 0.21g trimesic acid and 0.675g FeCl3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0046] (2) Add 0.5g of metal-organic framework material MIL-100-Fe and 8g of N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2 hours, then add 1.5g of polyvinylidene fluoride into the reactor, and stir at 60°C 4h, the composite mixture was obtained.

[0047] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0048] (4) Apply the spin coating method (the spin coating speed is 200r / min, and the spin coating time is 20s) to coat...

Embodiment 2

[0057] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

[0058] (1) 0.21g trimesic acid and 0.675g FeCl 3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0059] (2) Add 1g metal-organic framework material MIL-100-Fe and 7.5g N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2 hours, then add 1.5g polyvinylidene fluoride into the reactor, and stir at 60°C 4h, the composite mixture was obtained.

[0060] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0061] (4) Spin coating method (the spin coating speed is 1000r / min, and the spin coating time is 30s) is used to coat the mod...

Embodiment 3

[0068] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

[0069] (1) 0.21g trimesic acid and 0.675g FeCl 3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0070] (2) Add 1g metal-organic framework material MIL-100-Fe and 7g N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2h, then add 2g polyvinylidene fluoride into the reactor, stir at 60°C for 4h, A compound mixture is obtained.

[0071] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0072] (4) Spin-coating method (spin-coating speed of 300r / min, spin-coating time of 90s) is used to coat the modified casting solution on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com