Online separation reforming hydrogen production method capable of enhancing reaction efficiency and device for realizing method

A technology of reaction efficiency and hydrogen, applied in chemical instruments and methods, hydrogen separation, diffusible hydrogen separation, etc., can solve the problems of large volume, unsuitable for the utilization of miniaturized hydrogen production equipment, etc., to reduce reaction temperature, improve safety, The effect of reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

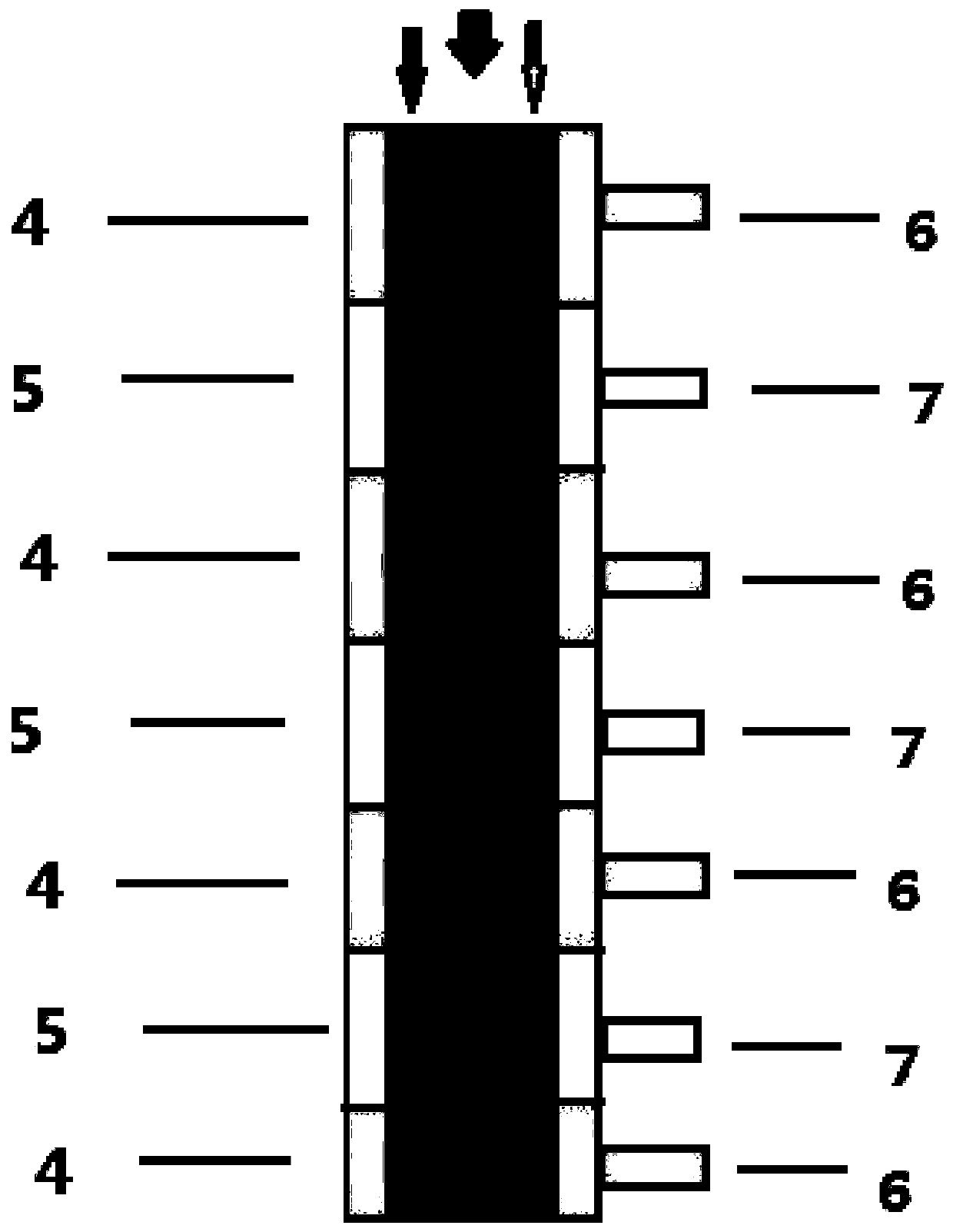

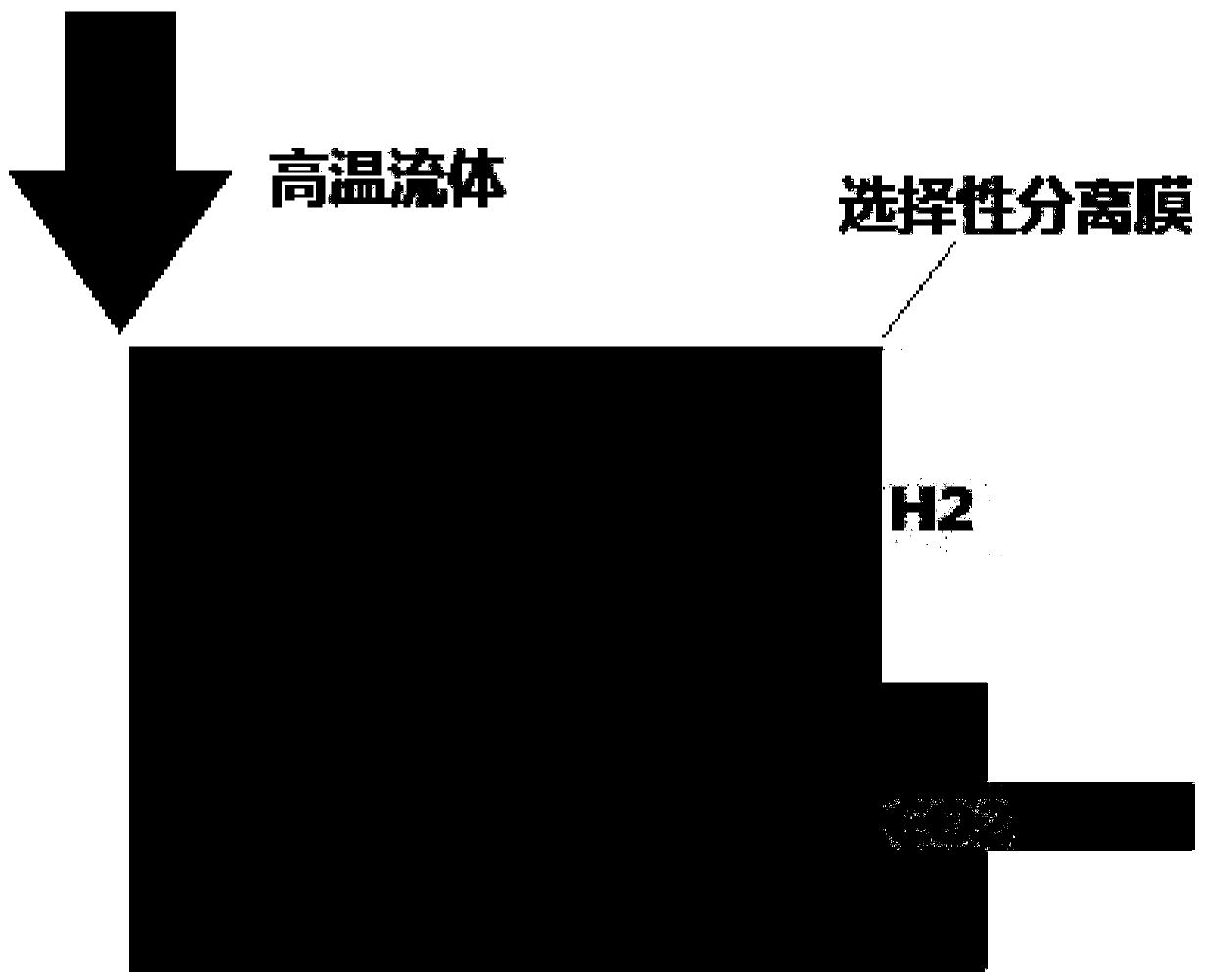

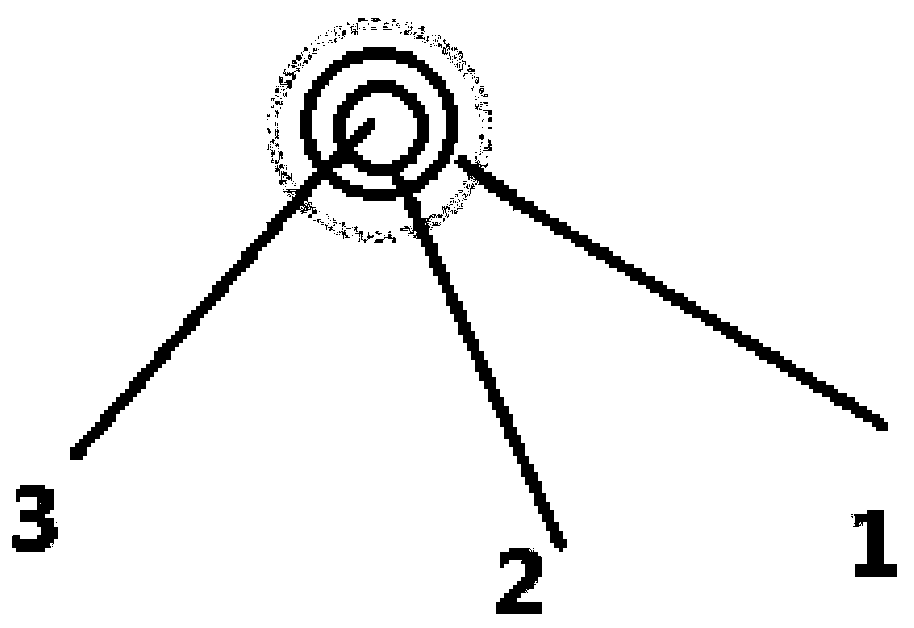

[0029] refer to figure 1 with 3 As shown, an on-line separation and reforming hydrogen production device (reactor) that can enhance reaction efficiency provided by the present invention is composed of three inner, middle and outer concentric tubes made of three different materials and upper and lower end caps. Three concentric circular tubes form three cavities, which are three cavities of the inner cavity (3), the middle cavity (2) and the outer cavity (1); The lower ends of the middle and outer chambers are sealed, and the upper end cover has multiple holes to provide high-temperature fluid inlets for the inner chamber and air inlets for the middle chamber; the outer wall of the inner pipe is coated with a reaction catalyst; the middle pipe adopts different selective separation The membrane is prepared to separate the gas products in the middle cavity to the outer cavity; the outer cavity is correspondingly isolated into different gas product areas, including the hydrogen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com